FSK Aluminium Foil for Glasswool Rockwool Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200000 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Introduction of Aluminum Foil Facing:

Aluminum Foil Facing is a kind of film, which is made of by Aluminum foil: 7 microns +Tri-way fiberglass scrim: M.D: 8/100mm; X.D: 12/100mm+ Polyethylene+Kraft paper: 50gsm (Natural) for Glasswool, Sandwich Panel, Wall Insulation, Roof Insulation

Application of Aluminum Foil Facing:

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Features of Aluminum Foil Facing

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Specification of Aluminum Foil Facing

CONSTRUCTION:

Aluminum foil: 7 microns

Tri-way fiberglass scrim: M.D: 8/100mm; X.D: 12/100mm

Adhesive: Polyethylene

Kraft paper: 50gsm (Natural)

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 88 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 110 50 | ASTM D828 |

Burst strength | N | 30 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

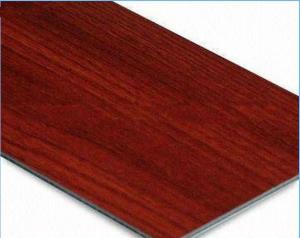

Pictures of Aluminum Foil Facing:

- Q: 9 meters high aluminum plastic door door fee is how much, Xuzhou area

- Xuzhou area of the labor costs should not be cheap. This highly operational estimates also need 80-120 yuan / square meter it.

- Q: Can aluminum panels be covered with self-adhesive coils to extend the life of aluminum-plastic plates by avoiding sun and rain? Or will it be closed by rain, humid airtight moldy, or reduce the service life?

- Aluminum-plastic plate is mainly afraid of oxidation, airtight should be to reduce the service life.

- Q: Aluminum engraving screen, aluminum hollow screen What are the advantages

- Can be made into a variety of patterns of relief, hollow screen, aluminum will not rust! The The Shang Yao metal products. The

- Q: Is the aluminum composite board the same as the aluminum composite panel?

- Aluminum composite core layer of mineral wool there are other environmentally friendly or special core material

- Q: I made a monitoring project, the bank inside the aluminum-plastic plate was I turned a hole. The above requirements we must rectify. Now want to ask you how to make up. I heard that the wrench is shipped over the sea. I'm thinking all about it all day.

- If you take into account the material is the road in OKorder, then you can also choose the same color of the same aluminum-plastic plate with it can be. As long as not a dedicated color, the general color market generally have some of the above.

- Q: Will the aluminum plate can make a wardrobe?

- can

- Q: Does the aluminum plate itself fire? Not aluminum plate

- Metal can not set fire to say that aluminum has heat absorption fast heat fast characteristics

- Q: Hello, how do you contact me? Need green aluminum plate, thank you!

- Mr. Liu, we have been contacted. The future of the window of the aluminum-plastic plate, the future of the window aluminum composite board. Asked by the green is not the meaning of the green, is a special color.

- Q: On the report of the project price per square meter engineering requirements is to use 50 * 5 angle iron keel with 4mmA grade aluminum-plastic plate dry hanging

- Skeleton production and installation of aluminum-plastic composite board for the plastic layer are pressed up and down a layer of aluminum sheet, and then in the aluminum plate surface by roller coated with fluorinated vinyl resin, made by baking, aluminum plate using mechanical milling, And leave a 0.3mm thick core material, so as not to hurt the inner surface of the panel. After the cut, fold, strengthen the ribs of the security system. Install the finished parts after installation

- Q: What is the composition of aluminum-plastic panels?

- Aluminum-plastic composite panels are made of multi-layer composite material, the upper and lower layers of high-purity aluminum alloy plate, the middle of non-toxic low-density polyethylene (PE) core board, the front also paste a protective film. For outdoor, aluminum-plastic panels coated with fluorocarbon resin (PVDF) coating, for the interior, the front can be non-fluorocarbon resin coating.

Send your message to us

FSK Aluminium Foil for Glasswool Rockwool Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200000 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords