Bj Geotextile Ltd Waterproof Geotextile Fabric Polypropylene Nonwoven Fabric for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

Geotextiles

Divider

Protect the integrity of your gabion basket installation with high-quality geotextiles between your gabion structures and the soil. We supply only the highest quality of both woven and non-woven geotextiles for gabion installations and other applications.

Geotextiles

These geotextile filter fabric materials prevent the migration of fine soils to the spaces between rock particles. The migration of fine soil into your gabion structure can cause subsidence problems below or behind the gabion structure in time if not applied correctly and will stir up problems – especially in sandy soils. Clay soils do not generally require a geotextile filter fabric as they seldom leach through the basket section. We recommend using a suitable geotextile where the gabion is in contact with earth, this will limit any movement of soils through a gabion structure. In soft soil foundations especially and wherever overlaps or joins are required, we suggest a minimum overlap of 300mm(1 ft).

We supply geotextile to all sites where gabions are used. Depending on the required structure of the gabion, we normally find that about 1-2m2 of geotextile per m3 of gabion is required

Protection: Geotextile when used as a protection layer acts as a cushioning barrier between the geosynthetic lining system and other layers of the dam or landfill cell. Generally the larger mass rolls of geotextile provide the best cushioning protection. As a protection barrier it helps prevent puncturing and leaks from external forces coming into contact with the liner.

Applications

gabions and river mattresses

roads

concrete retaining walls.

Separation

the separation of good and poor roadway layer work materials

roads over soft soils.

Roadway lining provides waterproofing qualities for layer works and wearing courses.

Drainage of

sports fields

railway tracks

behind concrete walls & embankments.

Membrane liner protection

geotextiles are permeable nonwoven fabrics used to separate, filter, reinforce, protect, or drain. Geotextiles allow filtration / separation of granular layers in roads and rail applications, used to protect membranes in landfill applications, used in coastal defence applications and used in Landscaping to protect surfaces and structures from weeds and root growth.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

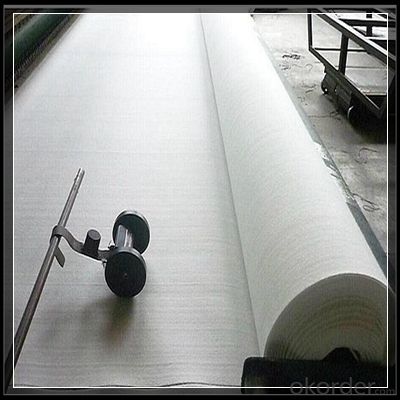

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles aid in the reduction of liquefaction?

- Geotextiles aid in the reduction of liquefaction by acting as a barrier that prevents the migration of fine particles during the occurrence of liquefaction. This helps in maintaining the soil's stability and increasing its resistance to liquefaction-induced hazards.

- Q: How do geotextiles help in preventing soil erosion in construction sites?

- Geotextiles help in preventing soil erosion in construction sites by acting as a barrier between the soil and the forces that cause erosion, such as wind and water. These synthetic fabrics are placed on the soil surface or embedded within it to stabilize the soil and enhance its strength. Geotextiles also improve filtration and drainage, reducing water flow velocity and preventing the loss of fine soil particles. By providing reinforcement and protection, geotextiles effectively mitigate soil erosion and maintain the stability of construction sites.

- Q: What are the factors to consider when selecting geotextiles for a project?

- When selecting geotextiles for a project, there are several factors that need to be considered. These factors include the type and purpose of the project, the required strength and durability of the geotextile, the site conditions and environmental factors, as well as the cost and availability of the geotextiles. Additionally, factors such as installation methods, compatibility with other materials and long-term performance should also be taken into account. Overall, a thorough understanding of the project requirements and careful evaluation of these factors will help in selecting the most suitable geotextiles for the project.

- Q: How do geotextiles contribute to the efficiency of drainage systems?

- Geotextiles contribute to the efficiency of drainage systems by providing two main benefits. First, they act as a filter to prevent soil particles from clogging the drainage pipes or systems, allowing for a consistent flow of water. Second, they help to distribute the water evenly across the entire drainage area, improving the overall effectiveness of the system.

- Q: Can geotextiles be used in mine tailings management?

- Yes, geotextiles can be used in mine tailings management. Geotextiles are often employed in the construction of tailings dams and containment structures to provide reinforcement, filtration, and separation. They can help improve the stability and strength of the tailings containment system, prevent erosion and seepage, and facilitate water drainage.

- Q: Can geotextiles be used for reinforcement of earthen dams?

- Yes, geotextiles can be used for the reinforcement of earthen dams. Geotextiles are commonly employed in dam construction projects to enhance the stability, strength, and erosion resistance of earthen embankments. They act as a barrier, preventing the loss of soil particles while still allowing for water drainage, thereby improving the overall performance and longevity of the dam.

- Q: I only know how many grams per gram of geotextile, but do not know what the meaning of this TS30? More

- Product specifications: equivalent to weight 126g / m2

- Q: GB / T geotextile sampling sampling frequency, 100 volumes equal to the number of square meters?

- Geotextile width is usually 6 meters long, 50 meters long or 100 meters. A roll area of 300 square meters or 600 square meters. 100 volumes are 300 * 100 square meters, or 600 * 100 square meters.

- Q: Do geotextiles require regular maintenance?

- Yes, geotextiles do require regular maintenance to ensure their effectiveness and longevity. This includes periodic inspections, removing any accumulated debris or sediment, repairing any damage, and monitoring their performance over time. Regular maintenance helps to preserve the functionality and durability of geotextiles in various applications.

Send your message to us

Bj Geotextile Ltd Waterproof Geotextile Fabric Polypropylene Nonwoven Fabric for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords