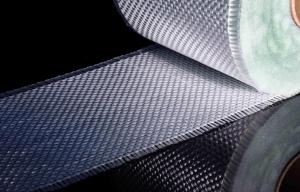

High Quality Roving Fiberglass Tape Woven Roving

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Woven Roving:

Fiberglass Woven Roving is mainly shuttle woven, producing an excellent appearance and using high performance. It is widely used in aircraft and space flight industry, ship industry, chemical industry, medical industry, military industry, sports goods, etc. It is available in manufacturing FRP fishing pole, golf pole, baseball bole, surfboard, sailboard, skis, ice stick, etc.

Application of Fiberglass Woven Roving:

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyester,viny ester and epoxy resins

Technical Parameters of Fiberglass Woven Roving:

Product No. | Density Ends/cm | Area Weight | Thickness | Width | Length | Breaking Strength(N) ≥ | ||

| ||||||||

Warp/cm | Weft/cm | g/M2 | Warp | Weft | ||||

EWR260 | 22 | 22 | 251-277 | 0.26 | 10~100 | 50~200 | 1100 | 900 |

EWR270 | 46 | 41 | 248-274 | 0.26 | 10~100 | 50~200 | 1800 | 1100 |

EWR300 | 32 | 18 | 296-328 | 0.3 | 10~100 | 50~200 | 1500 | 1100 |

EWR360 | 32 | 18 | 336-372 | 0.35 | 10~100 | 50~200 | 2000 | 1100 |

EWR400 | 32 | 23 | 400-430 | 0.4 | 10~100 | 50~200 | 2500 | 2200 |

EWR580 | 26 | 22 | 580-610 | 0.58 | 10~100 | 50~200 | 3850 | 3650 |

EWR600 | 20 | 16 | 600-645 | 0.6 | 10~100 | 50~200 | 4000 | 3850 |

EWR800 | 20 | 15 | 800-840 | 0.8 | 10~100 | 50~200 | 4600 | 4400 |

- Q: Who is going to handle the comonent joint of GRC in the exterior wall?

- Both of them should be tested. The installation process will handle it in surface flat, the rest of the process will continue.

- Q: What is the meaning of Glass fiber reinforced plastic purification tower ant medium

- raw materials and technical requirements of glass fiber reinforced resin purification tower production. Resin used in raw material resin manufacturing tower structure layer could be unsaturated polyester resin, epoxy resin, vinyl resin according to relevant requirements. According to the requirement by the supply and demand parties, both sides can choose other suitable winding resin after consulation. The resin used for corrosion resistant layer of the tower could be vinyl resin and epoxy resin according to relevant requirements. In accordance with the requirements of usage, they may also choose other resins with medium corrosion resistance after consultation. Unsaturated polyester resin should comply with the provisions of GB8237 and other resins shall comply with the corresponding standard. Generally speaking, resin should not contain pigments, dyes, fillers or colorants. Exception in the following circumstances: A) The materials we used does not interfere with the visual inspection of product quality and thixotropic agent does not affect corrosion resistance requirements of products ; b) if both parties agree, pigment, dye or colorant can be added into resin; c) if both parties agree, ultraviolet absorbent or flame retardant can be added into resin.

- Q: What are the causes and methods of glass fiber surface treatment?

- Heat - chemical treatment: first, the glass fiber textile products will be emulsified by paraffin wax and then be treated with surface treatment agent (mainly used for twisting textiles).

- Q: What parameters should be provided for the customs clearance of the glass fiber?

- After knowing specific custom code, you can check the elements for declaration at the custums net. The elements for declarationare mainly includes 1 material (glass fiber) 2 kinds (comb). However, we can not determine the custom code of glass fiber which proprably includes in the 7019 part.

- Q: Medium alkali glass fiber cloth

- It is mainly used for large and medium sized non-metal container, equipment, pipe and shell.

- Q: What is organic glass?

- Acrylic plexiglass (acrylic) , English Acrylic transliteration, is a combination of acrylic acid and methacrylic acid chemicals. Acrylic plate often is said to be poly methyl methacrylate (PMMA) plate, which is composed of methyl methacrylate monomer (MMA) polymerization. Acrylic plexiglass (acrylic) history can trace back to the early 20s, acrylic (PMMA), according to the polymerization,can be divided to casting plate (Cast Sheet points) and extrusion plate (Extruded Sheet), pultrusion into various sifferent hollow sections and organic glass acrylic (acrylic English) is Acrylic, UV resistant plate, plate and plate (also known as extinction silk matte board).Organic glass acrylic plate according to the transmittance can be divided into pure transparent plate, so the use of glass steel doors and windows for doors and windows can reduce the trouble, and basically the same life building. FRP glass fiber reinforced materials, acrylic plate is often said that the poly methyl methacrylate (PMMA) plate, this method greatly reduces the cost of MMA, The mechanical thermal curing pultrusion molding, high flexibility, anti-corrosion, casting industry is more suitable for small batch production of sheet metal of different colors, now most of the PMMA sheet called acrylic plate. Acrylic and organic glass all come from the brand name "Oroglas". However, more crack. Some people think that the transparent plastic plate is the organic glass, and molecular weight of casting plate is high. Acrylic plexiglass (acrylic) can trace back to the early 20s, oil and other corrosive media have special anti-corrosion function, high strength, sound insulation and so on.

- Q: How many types of glass fiber and what is escorting yarn?

- According to the yarn bundle, it can be divided into roving, fine yarn and textile yarn. According to production types, it can be divided into direct yarn and union yarn. Yarn can be divided into twisted yarn and felting yarn according to the degree of twist. According to the manufacturing products, it is divided into winding yarn and twistless yarn.

- Q: What is the material of glass steel? How to make it?

- Glass fiber reinforced plastic is a kind of composite material. It is common in everyday life. As a typical composite material, it is made by glass fiber and epoxy resin. In general, the glass fiber should be woven into a glass cloth, and then mix with the epoxy resin, the glass fiber reinforced plastic can be made after expoxy resin solidition. Epoxy resin itself is toxic, but the chemical properties is stable, and it is not harmful to human after solidation.

- Q: What is the difference glass fiber roving and fine yarn ? Does the equipment used for production have any difference.

- 6 microns non-alkali, 9 micron twistless roving (bulk yarn), 80 alkali , 30 twist roving ans 21 medium alkali. It is a glass fiber integrated production enterprises combined management, scientific research and development. The company has advanced production equipment and strong technical force. Main production includes 30 alkali-free glass fiber yarn and 40 fine yarn with annual production of 1500 tons.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Roving Fiberglass Tape Woven Roving

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords