Coated Alkali-Resistant Fiberglass Mesh Cloth (siva filesi)

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m2 m²

- Supply Capability:

- 1x40HQ Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

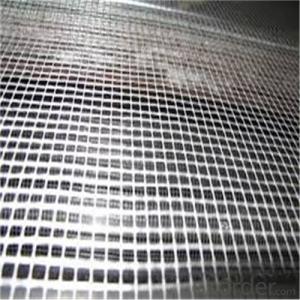

Specifications of Coated Alkali-Resistant Fiberglass Mesh Cloth (siva filesi)

Coated Alkali-Resistant Fiberglass Mesh Cloth (siva filesi) is mainly alkali-resistant fiberglass fabric, it use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's an ideal engineering material in construction and decoration industry.

Coated Alkali-Resistant Fiberglass Mesh Cloth (siva filesi)

Mesh size: 5mm x 5mm, 4mm x 4mm, or 4mm x 5mm

Weight/m2: 75g-160g

Length/roll: 50m-100m

Width: 1m

Color: white, blue, orange or other colors

Special spec can be ordered and produced by the requirements of customers

Usage/Applications of Coated Alkali-Resistant Fiberglass Mesh Cloth (siva filesi)

Coated Alkali-Resistant Fiberglass Mesh Cloth (siva filesi) used in insulator layer of reinforcement in the mortar, through shrinkage and temperature changes by providing a space to maintain movement between the layers, prevent crack and rupture due to shrinkage or temperature change

Packaging & Delivery of Coated Alkali-Resistant Fiberglass Mesh Cloth (siva filesi)

Packaging: Each roll is shrink-wrapped, or to be packed in plastic bag. Then rolls are put into pallets and cartons.

Delivery: About 25 days after confirming the order.

Characteristics of Coated Alkali-Resistant Fiberglass Mesh Cloth (siva filesi)

1. Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

2. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

3. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

4. Strength retention rate> 90%, elongation <1%, the durability of more than 50 years.

5. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

6. Good impact resistance and not easy to be teared.

- Q: What is the difference of the interior wall mesh and external wall mesh?

- The external mesh is mainly with the raw material of alkali, and then becoming a Mesh through various processes. Stability is very strong, the intensity is great, at the time of construction is also simple, it usually acts as insulation, is a professional mesh. Compared with the interior wall, it is a collection of fibers made with a good flexibility. Due to the differences of the local environment, the tensil force of the exterior wall is much better than the interior wall.

- Q: What are the main applications of fiberglass mesh?

- Wall reinforcement materials (such as glass fiber wall, net cloth, GRC wallboard, EPS internal and external wall insulation board, gypsum board and so on

- Q: Should gridding cloth be added when painting the inside corner of infilled wall and concrete column or shear wall?

- It should be added, or crack may appear.

- Q: The hardware cloth and the Mesh, which is better for the the thermal insulation ?

- The steel mesh is better. Wall brick wall with steel mesh drying binding configuration can well achieve the required positive pressure body wall strength to prevent cracking of the wall, out of shape the whole building substandard buildings. So the best selection of wall insulation effect with thermal insulation effect also has an enhanced role in the robustness of the building product is steel wire mesh, and the mesh is more suitable for the installation painting.

- Q: What's the gridding cloth? What's the application of them?

- With glass fiber woven fabric as base material, gridding cloth is processed with high alkali emulsion. GRC products are featured by high strength, lasting alkali resistance. Cement and concrete products, GRC wallboard and GRC components.

- Q: The costs of posting mesh are reasonable?

- It is mentioned to stick mesh in the construction technology which is included in the unit price. But in the process of construction, the foreman insisted on separate charge for the cost of the mesh, this is reasonable? T The process content in the Contract is as follows : 1: cleaning brush metope beauty solid nest wall again, 2: the nest bottom paint plaster leveling, 3: brush the nest wall fixed grid cloth, 4: the nest easily shave - 400, 2-3 times, 200 - watt bulb light and grinding smooth, brush primers, 5: Excluding special wall treatment, such as required gray sand leveling, the cost of another 15 yuan per square meter. 6: This offer provides paint, roller, brush wool and other disposable utensils from Party A. 7: To paint additive color is no more than two colors, one color for each additional should plus $ 150.

- Q: For puttying in decoration, anti-cracking fiberglass mesh or dacron cloth is widely used on walls. What are the correct constrcution order and method?

- For board joints, use white latex strip of cloth to attach bar-type anti-cracking cloth at the seams, and once it's not firm, brush some white latex again.

- Q: Under what wall does it need to pave glassfiber mesh completely? Plastering inner wall or exterior wall, which one is it applied to?

- This is just an industrial?standard. It is called adhesive?sticker, but it is rarely used to do so because of cost. And it is rarely used at home. As for paving mesh completely or joint tape, it can be plastering exterior wall. Plastering inner wall is generally used in seam crossing of wall (there is mesh specially for jionts, but it is required that plastering inner wall is used in most fiberglass mesh. It's too expensive, and there is no need to do that.)

- Q: What is the glass fiber board?

- Glass fiber board, that is glass fiber synthetic board, is made of glass fiber material and high heat resistant composite material, it does not contain asbestos components harmful to human body.

- Q: What consequence will using non-alkali resistant fiberglass mesh cause in thermal insulation construction?

- Fiberglass mesh used for external wall of buildings is equivalent of soft rebarIn this application Building Exterior fiberglass mesh plays the role of soft steel construction using alkali fiberglass insulation effect did not work needs to FIG alkaline fiberglass mesh outer coating (slurry) alkali-resistant fiberglass corrosion

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Coated Alkali-Resistant Fiberglass Mesh Cloth (siva filesi)

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m2 m²

- Supply Capability:

- 1x40HQ Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords