Ceramic Fiber Blanket for Glass Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Blanket for for Glass Plant

Composite of Ceramic Fiber Blanket for Glass Plant

Ceramic Fiber Blanket for Glass Plant is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Types of Ceramic Fiber Blanket for Glass Plant : ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products used different materials. Performance of Ceramic Fiber Blanket for Glass Plant also has difference, and they are suitable for different working temperatures.

Main Features of the Ceramic Fiber Blanket for Glass Plant

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Application of Ceramic Fiber Blanket for Glass Plant

◆Petrochemical process heater refractory fiber lining

◆General furnace backup insulation

◆Heat treating furnace or intermittent(shuttle) kiln hot face lining

◆Electrical insulator

◆Heat seals for kiln car or furnace door

◆High temperature acoustic

◆Fire protection

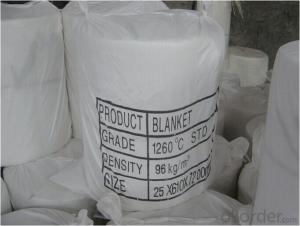

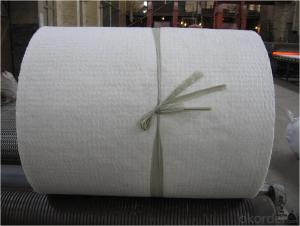

Ceramic Fiber Blanket for Glass Plant Images

Ceramic Fiber Blanket for Glass Plant Specification

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotlessly white | spotlessly | spotlessly | spotlessly | |

white | white | white | |||

Density (kg/m3) | 64,96, | 64,96, | 64,96, | 64,96, | |

128,160 | 128,160 | 128,160 | 128,160 | ||

Shrinkage on heating (%) | ≤3 | ≤3 | ≤3.5 | ≤3.5 | |

(24 hours, density as 128/m3) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.15(800°C) | 0.176(800°C) | 0.18(1000°C) | 0.23(1000°C | |

0.17(1000°C) | 0.22(1000°C) | 0.26(1200°C) | 0.31(1200°C) | ||

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

(density as 128kg/m3) | |||||

Chemical | AL2O3 | 45-47 | 45-46 | 53-55 | 38-54 |

composition | AL2O3+SIO2 | 98.5 | 99 | 99 | 82-90 |

(%) | ZrO2 | - | - | - | 10-18 |

FAQ of Ceramic Fiber Blankt for Glass Plant

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q8:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

- Q:I bought grapefruit diet pills i read u can use them to lose weight how much weight will i lose and how fast?

- 1.) 6 grams 2.) 3.2 grams 3.) 2.0% hydrogen, 32.7% sulfur and 65.2% oxygen 4.) ? 5.)?

- Q:What are some yummy high fiber low fat foods :)?

- This website has a variety of recipes using high fiber/low fat foodsHope ths helps.

- Q:Be serious hereHow do you record without a studio, but in a quiet room with a recorder and still make it sound professional.

- The only animals you will come across there in houses are the ones that look like you and myself :-)

- Q:will it be high in fiber

- Wood chips may be dangerous for your digestive systemSome foods that are high in fiber that are good for getting the 'ole digestive system going are spinach, broccoli, and pretty much any green veggieSpinach is really high in fiber as well as vitamins.

- Q:I am looking to make a solar power hot dog cooker for a class project.I have pretty much decided on the tin-foil parabola design most website suggest, however I'd like to augment it with insulationLet me know what you think might work best, and why:The major idea I had was to enclose my cooking area by either black paper, saran wrap, or perhaps a glass containerThe idea is that the IR light would still hit the hotdog, but less air that was heated around it would escapeIf I use black paper though, I might absorb the energy before actually hitting the hot dogClearly using tin foil would reflect it back out against the original reflectors.Let me know what you think.Thanks!

- Saran wrap could easily melt and is not very easy to maneuver to pull out the hot dogs when they are finishedthe black paper is a bad idea since it would block all of the radiant energy that you are hoping will reach the hot dogsI would go with the glass coverThere are glass covers that one puts over cheeses to keep them freshThey are not huge, but would be enough to do 4 - 5 hot dogsThat would be the most elegant solutionIf you cannot find one of them, you could glue 5 pieces together with silicon sealantThat should work tooSilicon sealant can handle quite high temperaturesThere are varieties in auto supply stores that can handle up to 600 degrees F, but you do not need anything near to that highYou could use small steel 'corners'to make it more stable Glue them to the glass with the same sealantyou could use them on the outside and inside of the glass, at, say, two per edge: so you'd need 16 of themWell, a fish tank would also work, if you can relocate the fish!

- Q:can you make yarn (knitting) out of cotton balls? if so then how?i have alot of cotton balls and i want to know if i can make yarn out of them? can you also tell me directions on how to do so? i cannot find anything on it on google!

- What id say mate is to first finish off the drywall first then start on the stair case

- Q:I want to naturally dye yarn

- Safflower (carthamus tinctorius) is a common food and dye plant in many parts of the worldIt bears yellow flowers which contain both yellow and red pigments within the blossomsIt has been used for centuries as a true saffron substitute and adulterantAnother name one sees it referred to is poor man's saffronIt is a useful plant with seeds which are used to produce safflower oil and meal for feeding livestockHowever, as the botanic name tinctorius indicates, it best known as a dye plantTo extract the yellow for coloring food saffron yellow the plant just needs to be steeped in a mildly acidic solution like a soup brothTo dye cloth or fiber yellow, the petals need to soaked in a mild vinegar solutionBobbi McRae in COLORS FROM NATURE recommends a cup of vinegar to a gallon of waterLike madder, heat is the enemy of good color extraction in safflower, so just soak the petals over night in the vinegar water or make a sun tea of everything and let it sit for a few days in the sun.Strain out the petals working them a bit to extract the last of the yellow To obtain the red within the petals wash the last of the yellow out (after the vinegar extraction) with water agitating them a bitStrainThen place the washed petals in fresh water and add some ammonina, or washing soda to create a basic solution as opposed to an acidic oneAgain like madder, a basic solution helps extract the red tones in the plant matterSoak overnight or as a sun teaIf in a rush, you can heat the solution to 150 degrees F, but proceed very cautiouslySafflower seems to like heat even less than madder if you want to extract a nice red tone.

- Q:Does anyone know of a Drin Houston that doesn't use Statin Drugs for high cholesterol and high triglycerides? I am taking TWO statins and want to get off of at least one, if not both of themI would like to find someone with experience in doing this treatment.Thanks!

- I'm a 45 year old woman and was recently diagnosed as being a borderline diabeticMy doctor prescribed some medication, but before filling it I decided to do some research on the internet which led me to the methodsAfter reading this ebook and applying the methods, my scepticism turned to 100% beliefI noticed that my energy levels increased significantly and I felt more rested in the morning, my symptoms started going awayI am very happy to tell you that I have been feeling better than I have felt in years and my doctor informed me that he will be taking me off my prescriptions if I keep this upI recommend you use the Type 2 Diabetes Destroyer to naturally reverse your diabetes.

- Q:I'm about 280 pounds and shopping for a new mattressIf you have experience please let me know how thick your mattress or possibly the brandI'd rather not sink to the box spring but I'm not a fan of a firm mattressAny advice would be great, thanks!

- If the choice is between these two, the chrom-moly will do betterAluminum is subject to work hardening or stress hardening.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket for Glass Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords