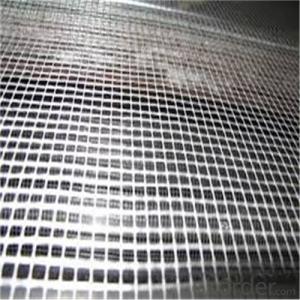

Cement Board Fiberglass Mesh Tape - High Quality, Low Price Fiber Glass Mat

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

CORE MAT is a stratified reinforcing glass fiber fabric composed by 5 layers. 2 exterior layers of random mat, 1 layer of woven roving and 2 layers of synthetic fibers. The main application is for RTM and RTM Light parts where mechanical performance is a must.

CONSTRUCTION

CORE MAT has been manufactured by stitch bonding technology. The 5 layers are arranged as follows:

Layer 1: Random glass fiber mat

Layer 2: Synthetic Web

Layer 3: Woven roving

Layer 4: Synthetic Web

Layer 5: Random glass fiber mat

The layers 2 and 4 are made by a synthetic material (polypropylene)and the main purpose of these layers is to allow the resin flow and provide compressibility to the reinforcement.

STYLES

The standard materials are the ones in the following list, but other designs are also available according to customer needs

How to understand CORE MAT description:

Example:

250BWR500B250

L. 1(250): 250 G/M2 of mat

L. 2(B): Synthetic material

L. 3(WR): Woven roving 500G/M2

L. 4(B): Synthetic material

L. 5 (250): 250 G/M2 of mat.

| Specification | Glass fiber G/M2 | Total dry weight G/M2 |

| 250BWR500B250 | 1000 | 1250 |

| 350BWR500B350 | 1200 | 1450 |

| 450BWR500B450 | 1400 | 1650 |

| 250BWR800B250 | 1300 | 1550 |

| 350BWR800B350 | 1500 | 1750 |

| 450BWR800B450 | 1700 | 1950 |

- Q: A brief introduction to glass cloth of glass fiber cloth

- The continuous strand felt is formed from the glass filament in the drawing process or from the original filament cylinder, and the continuous filament is 8 in shape. It is deposited on the continuous moving mesh belt and bonded by powder binder. The fiber in continuous glass fiber felt is continuous, so its strengthening effect on composites is shorter and the felt is good. Mainly used in pultrusion, RTM, pressure bag and glass mat reinforced thermoplastics (GMT) and other processes.

- Q: What are the requirements for wall insulation fiberglass mesh?

- Mesh is made of glass fiber as the main raw material, but also through multi-processing procedures. The interior wall mesh is an ideal material of grc wallboard. In general, the unit weight of interior wall thermal insulation mesh is lighter, usually about 50-60 grams, so its quality tensile resistance is relatively smaller. The weight of exterior wall thermal insulation mesh is generally 80-160 g, according to different building categories, the application of grams is not the same, It is better to apply it in external wall to resist tensile force .

- Q: How to use gridding cloth tape, namely glass fiber self adhesive tape?

- Use it with the case sealing tape.

- Q: Does it is required to paste mesh in which has ben pasted with wallpaper?

- Otherwise, the later wall cracks will also affect the wallpaper. Now, the walls has been re-covered with cement. Intend to shovel all red bricks and then cover cement.

- Q: Is the plastering of the window opening necessary to hanging the mesh.

- Newly renovated house, usually newly built, will produce a slight crack, but it is not serious. as for the lightweight walls, it can also use kraft paper to repair, not necessarily to use mesh.

- Q: How much does mesh paving cost??

- It costs about ?20 to 50.

- Q: The original walls have been posted withmesh. Now the quality is very good without drum kits and cracking, is it neccessary to be removed when decorating?

- There is no need. If you want to paste the wallpaper, you don't need to remove it and the painting of the wall is also not needed.

- Q: For a woven glass fiber mesh cloth work

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.

- Q: How much damage does glass fiber do to humans?

- Glass fiber is a kind of inorganic nonmetallic material with excellent properties. English name is: glass fiber. It is prepared by high temperature melting, wire drawing, winding and weaving process with glass balls or waste glass as. All kinds of products formed finally, glass fiber monofilament diameter from a few microns to twenty micron, the equivalent of a hair 1/20-1/5, each bundle of fibers are hundreds or even thousands of root root filaments, usually as a reinforcing material of complex materials, electrical insulating materials and insulation materials, circuit board, etc. and widely used in various fields of the national economy.

- Q: How to clean fiberglass mesh?

- It needn't to be cleaned.

Send your message to us

Cement Board Fiberglass Mesh Tape - High Quality, Low Price Fiber Glass Mat

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords