High Quality Glass Wool Roll for Thermal Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass wool blanket for thermal Insulation

1.Structure of Glass wool blanket for thermal Insulation:

Glass wool is an industrial product made by spinning glass into a fibrous material that can be packed in mats and blankets. This product is used as insulation and in other applications, like for air filters. It is available through home supply stores and manufacturers can also produce wools for special purposes, like insulation in aircraft, where the standards may be higher for health and safety reasons.Glass ool blanket with aluminum foil surface has good capability of heat radiatin protection.

2.Main Features of Glass wool blanket for thermal Insulation:

The glass wool blanket is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including blankets, boards and pipes.These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

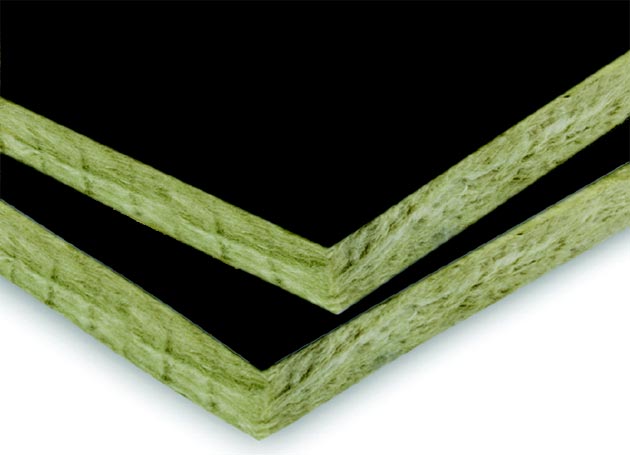

3. Glass wool blanket for thermal Insulation Images

4. Glass wool blanket for thermal Insulation Specification

The glass wool blanket is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

The glass wool blanket with aluminum foil surface has good capability of heat radiation protection.

The glass wool blanket with aluminum foil surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 10-32 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 10000-30000 |

Both unfaced and faced felts can be provided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the raw materials of centrifugal glass wool?

- The main raw materials of good centrifugal glass wools which are made of industrial chemicals like borax are natural ores like quartz sand, limestone, and dolomite, with some pure alkali.

- Q: what is the quota of glass wool rigid section of thermal insulation.

- Now, I also encountered the same problem, lz, can you tell me what quota should be used?

- Q: What performance characteristics does aluminium foil ultra-fine glass wool board have?

- Performance: ① It has good thermal insulation property at high and low temperatures. 2, It has performance of thermal insulation and fire-resistent partition. 3. It has excellent sound insulation and sound absorption performance. Hope it will help you out!

- Q: What are the uses of glass wool thermal insulation materials?

- Thermal and sound insulation of steel structures, thermal insulation and fire prevention of external walls.

- Q: Polyester and glass wool, which is better, and why?

- The first one is better, it has good flexibility.

- Q: Now what is the latest color steel sandwich board? such as: Foam, stretches, glass wool

- it is better to use rock wool because it is fireproofing and sound insulation.

- Q: How about the quoted price of asphalt glass wool felt?

- Unit price of asphalt glass wool felt: RMB 2400.00 yuan per ton.

- Q: What is the function of glass wool foil?

- Glass wool is one kind of the glass fiber and it is a man-made inorganic fiber. Glass is made by melting such raw materials as quartz sand, limestone, dolomite and other natural ore with some chemical materials like pure alkali and sodium borate. In the molten state, the glass is thrown into fine fibers in the shape of floc by the with external force. These fibres vertically interwine and show many small gaps. These gaps can be regarded as air void. Thus, glass wool can be regarded as porous materials and it is of good insulation and sound absorption performance.

- Q: Rubber and plastic or glass wool, which one more suitable for suspended ceiling thermal insulation materials?

- The cost of rubber and plastic is high and that of glass wool is low.

- Q: What is the density of glass wool?

- Glass wool, a man-made inorganic fiber, belongs to a kind of glass fiber. It is a spongiform material made through fibration of melten glass. It is an inorganic fiber whose chemical components belong to glass, having good formability, low bulk density, low thermal conductivity, good thermal insulation and sound absorption, corrosion resistance and chemical stability. For centrifugal glass wool whose thickness exceed 5 cm and unit weight is 16Kg / m3, the sound absorption coefficient of low frequency125Hz is about 0.2, and that of middle and high frequency is close to 1. When the thickness continues to increase from 5cm, the low-frequency sound absorption coefficient also increase gradually. When the thickness is greater than 1m or more, 125Hz low frequency sound absorption coefficient will also be close to 1. Thicknesses of acoustic glass wools often used in architectural acoustics are 2.5cm, 5cm, 10cm, and unit weights are16,24,32,48,80,96,112kg / m3. centrifugal glass wool whose thickness is 5 cm and unit weight is 12-48kg / m3 is usually used.

Send your message to us

High Quality Glass Wool Roll for Thermal Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords