High Quality Glass Wool Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 700 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass wool Board for thermal Insulation

1.Structure of Glass wool Board for thermal Insulation:

Glass wool is an industrial product made by spinning glass into a fibrous material that can be packed in mats and Boards. This product is used as insulation and in other applications, like for air filters. It is available through home supply stores and manufacturers can also produce wools for special purposes, like insulation in aircraft, where the standards may be higher for health and safety reasons. Numerous companies make glass wool products along with lines of other insulation materials for a variety of applications.

2.Main Features of Glass wool Board for thermal Insulation:

The glass wool Board is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including Boards, boards and pipes. The advantage of this material is numerous: noncombustible, nontoxic, and resistant to corrosion. It has low weight, low thermal conductivity, stable chemical property, low moisture rate and good hydrophobicity. These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

3. Glass wool Board for thermal Insulation Specification

The glass wool Board is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

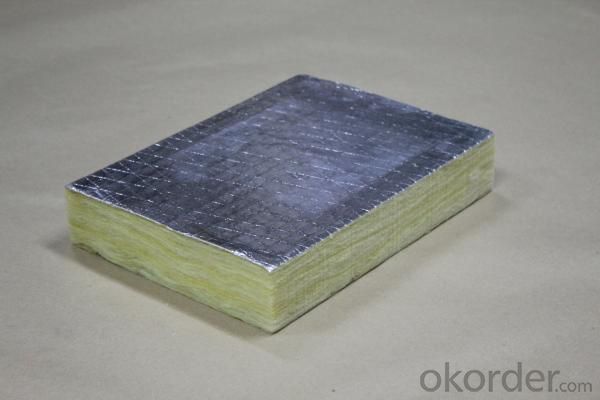

The glass wool Board with aluminum foil surface has good capability of heat radiation protection.

The glass wool Board with aluminum foil surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 24-96 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 600-1200 |

Both unfaced and faced felts can be provided.

4.Glass wool board image

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the raw materials of centrifugal glass wool?

- The main raw materials of good centrifugal glass wools which are made of industrial chemicals like borax are natural ores like quartz sand, limestone, and dolomite, with some pure alkali.

- Q: Does curtain wall glass wool belong to thermal insulation wool?

- , the general it is mineral wool.

- Q: what is the quota of glass wool rigid section of thermal insulation.

- what is the meaning of your words! are you asking the size! (I am a thermal insulation material wholesalers and if you have any questions please ask me)

- Q: Whether the combustion performance of glass wool blanket can reach A grade

- Yes, it itself is grade A incombustible?material.

- Q: Centrifugal glass wool board and polyurethane foam, which has better thermal insulation performance?

- The performances maybe are similar, of course, glass wool board with different unit weight, will also be different. Techniques are almost the same. Centrifugal glass wool board has better performance than that of polyurethane foam insulation materials in fire resistance.

- Q: Can mineral wool, rock wool and glass wool thermal insulation be applied to inverted roofs?

- And wall insulation material can be applied to all kinds of roofing. Glass curtain wall Steel structures are basically solid material hanging while facade walls need adhesive and fixation and other processes.

- Q: What's the necessary performance tests lass wool used for steel structure need to do?

- Generally it doesn't need to do the experiment, but some party A will demand for thermal insulation test, you can ask the local supervisor for samples manual and show it to party A, there is no test on steel structure columns.

- Q: These two kinds of glass wool are used as insulation materials, but one keeps 0.3 in specific gravity while the other keeps 0.5 in specific gravity. Which one should be chosen?

- Generally, materials with high density have better insulation effect, consequently leading a relatively higher price. You can make a layer of polyurethane on the outside. Specific gravity is another way of saying density. Materials' thermal insulation effect is related to density. So if you want to get better thermal insulation effect, you can make a layer of polyurethane on the outside. It is noted that common polyurethane has a maximum temperature of 100 degrees, while high-temperature polyurethane requires 120 degrees.

- Q: How to use glass wool for filtering?

- you can use buchner funnel or filter paper, specific question needs precious analysis, it mainly depends on the filter state, if solid particles are large, you can directly use ordinary funnel but not filter paper, when solid particles are small, you can use filter paper.

- Q: What is the density of high-temperature glass wool ?

- Sound absorption characteristics of glass wool depends on its thickness and density as well as overlay of pavement materials and structure. When applied to practical situations, we should also take into consideration of the cost, appearance, fireproof property, moistureproof, dust, anti-aging.

Send your message to us

High Quality Glass Wool Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 700 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords