Convention Display Stands

Convention Display Stands Related Searches

Display Stands Poster Display Stands Exhibitions Stands Portable Display Stands Fabric Display Stands Trade Fair Stand Stand Up Storage Containers Portable Display Led Display Supplier Tilt Panel Props Commercial Truck Shelving Led Message Display Board Decorative Metal Ceiling Panels Staff Lounge Waiting Chairs Small Programmable Led Display Used Reception Chairs For Sale Indoor Led Display Board Digital Led Display Board Stand Up Wardrobe Closet Retractable Drawer Slides Van Floor Storage Drawer Units Large Plastic Panels Cieling Panels Acrylic Cladding Panels Led Scrolling Message Display Armless Reception Chairs Led Digital Display Board Curtain Panels Electronic Display Board Electronic Message DisplayConvention Display Stands Supplier & Manufacturer from China

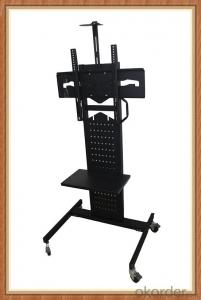

Convention Display Stands are an essential component in the marketing and advertising industry, providing an effective way to showcase products and attract customers' attention. These stands are designed to hold various items, such as brochures, pamphlets, and other promotional materials, making them versatile for different types of events and exhibitions. Their compact and portable nature allows for easy transportation and setup, ensuring that businesses can maximize their marketing efforts without incurring significant logistical challenges.Convention Display Stands are widely used in a range of settings, including trade shows, conferences, retail stores, and other promotional events. They serve as an eye-catching platform for displaying products and engaging with potential customers, ultimately boosting brand visibility and sales. These stands can be customized to fit specific marketing needs, with various materials, sizes, and designs available to suit different preferences and requirements.

Okorder.com is a leading wholesale supplier of Convention Display Stands, offering a vast inventory of high-quality products at competitive prices. With a commitment to customer satisfaction and a focus on providing exceptional service, Okorder.com ensures that businesses can access the display stands they need to enhance their marketing efforts and achieve their goals.

Hot Products