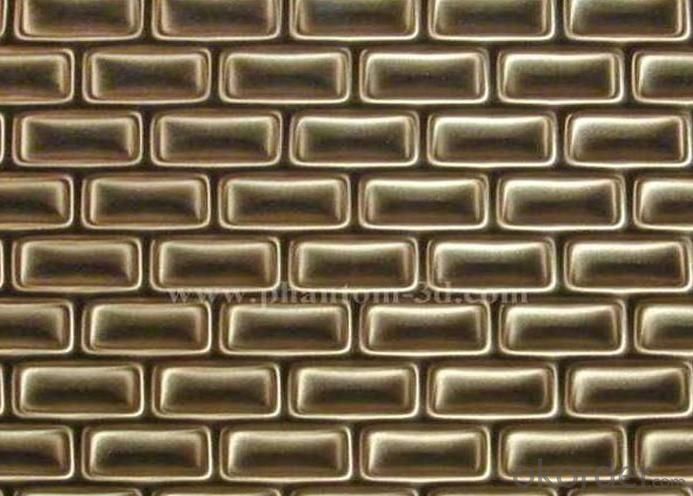

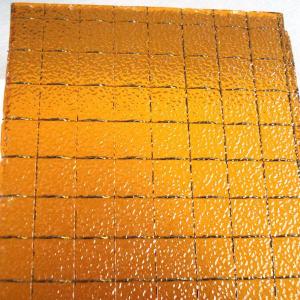

3D Float Glass/Decorative Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Square Meters m²

- Supply Capability:

- 12000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of 3D Float Glass, Decorative Glass

Max Size:1830*2440mm

Standard Size:300*300mm,600*600mm, thickness:5mm,6mm,8mm,10mm

Raw material: float glass (car grade), can be tempered.

Standard size: 1.83m(W) x 2.44m(L) x 5mm(thickness), 300mm x 300mm, 300mm x 600mm, 600mm x 600mm, can be made to order.8mm,10mm,12mm and 15mm thick are available.

Pattern: 22 series, cloth, volcano, vertical, barcode, rock, etc.(More patterns will be designed)

Color: 14 colors, purple, black, gold, China red, blue, etc.(more colors are expected)

Performance: It's a kind of environment friendly item which is processed by surface technology and appears stereoscopic and vivid optic effects, it can substitute or match with ceramic tile, stone, mirror, wallpaper for interior decoration, the panel can be cut into desired size or shapes, also you can choose standard tiles for DIY matching.

Application of 3D Float Glass, Decorative Glass

a. public decoration: hotel, KTV, bar, club, restaurant, office, etc.

b. home decoration: living room, bed room, bath room, kitchen, etc.

c. used on wardrobe, cabinet, etc.

Delivery time: 15-20 days

Packing: packed in wooden case, every pc of glass is protected by PE foam film.

- Q: What chemicals can be made from glass, paper, detergents, etc?

- Common is soda ash. Glass has silica, soda ash, sodium carbonate, high temperature heating. Paper generally use cellulose, bleaching powder. Detergent (mainly soap), usually sodium stearate

- Q: How can glass frosting be formulated? What raw materials do you use?

- The frosting frosting liquid before configured with plastic (or bamboo sticks) fully stir until frosting, and then prepare the medicine 80 mesh will be good all the time was filtered, the filtrate into the box (with sand sprinkling), filter residue (crystal) with plastic barrels (good to be frosted glass after the completion of the work, with 80 of the screen will put back the crystal installed frosting solution is dissolved, so repeated operation, the filter residue (crystal) can recycling, prolong the service life of frosting liquid).

- Q: Polypropylene short fiber and glass fiber if different

- Polypropylene fiber is resistant to acid and alkali, and glass fiber has poor alkali resistance.

- Q: What's good with a cup?

- Pure porcelain, porcelain, glass, these basic is non-toxic and good some of the porcelain. The problem is that plastic, buy when you should pay attention to:1. see, look at the material are impurities.2., smell, if there is a pungent odor, it is recommended not to buy. Attention to drinking hot water, this cup is very bad for the body.

- Q: What are the anticorrosive materials for glass fiber reinforced plastic?

- Finished product protection: because the construction environment belongs to the pool irrigation, it is not conducive to the curing of epoxy forming, so it must take 48 hours curing time, to be fully cured after use.

- Q: What are the raw materials for low dielectric glass fiber?

- Glass fiber is a kind of inorganic nonmetallic material with excellent properties. English name is: glass, fiber or fiberglass. Composition of silica, alumina, calcium oxide, boron oxide, sodium oxide, Magnesium Oxide etc.. It is prepared by high temperature melting, wire drawing, winding and weaving process with glass balls or waste glass as. All kinds of products formed finally, glass fiber monofilament diameter from a few microns to twenty micron, the equivalent of a hair 1/20-1/5, each bundle of fibers are hundreds or even thousands of root root filaments, usually as a reinforcing material of complex materials, electrical insulating materials and insulation materials, circuit board, etc. and widely used in various fields of the national economy.

- Q: What is inorganic glass?Want to be a fish tank, where can I find inorganic glass?

- Organic glass fiber reinforced plastics are polymers, PMMA, molded or extruded, or poured directly from the monomer MMA. The inorganic glass is quartz glass, which is what we usually see

- Q: What are the main materials for making glass?

- The melting point of silicon dioxide is very high, in order to achieve this Rongdian is very limited. The ancients had to add some other substances when it becomes low melting temperature. When silica melts down also very obtrusive in the process of heating without gradually filtering transition soft, into some other the material of the glass can be in different temperature range all the splendor, powerful shaping operation and effective setting. This substance is a flux.The flux is generally containing sodium oxide, potassium oxide, lead oxide, calcium oxide, barium oxide and other materials, such as limestone, feldspar, sodium carbonate, boric acid, lead compounds, barium compounds. (sodium oxide can reduce the viscosity of glass forming, the glass is easy to melt, plays a good role in flux; barium oxide in glass the formation plays a basic role with sodium oxide; tin oxide can increase the glass chemical stability and mechanical strength; lead oxide can increase density, improve hunting, with special luster; lead can make a glass of light refraction and scattering rate of small glass makes more lustrous and stable.

- Q: What raw materials are used for glass fiber reinforced plastics? Where can I buy them?

- Glass fiber reinforced plastic is not a steel, but a composite material. Glass fiber reinforced plastic products are widely used. Most of the facilities of yachts, automobiles, water storage tanks and highways are made of glass fiber reinforced plastic products.

- Q: Samsung LCD panel information

- Landlord, you take this screen is not the LCD screen, and the other is the plasma screen.It should be a 46 inch plasma TV set.

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2002 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | |

| Company Certifications | ISO 9001:2000;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | shen zhen,guang zhou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | High and/or Average |

Send your message to us

3D Float Glass/Decorative Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Square Meters m²

- Supply Capability:

- 12000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords