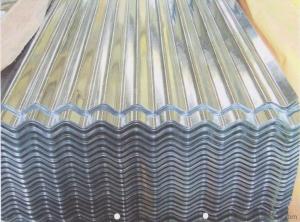

Aluminum product for corrugated

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

Aluminium foil has a shiny side and a matte side. The shiny side is produced when the aluminium is rolled during the final pass. It is difficult to produce rollers with a gap fine enough to cope with the foil gauge, therefore, for the final pass, two sheets are rolled at the same time, doubling the thickness of the gauge at entry to the rollers. When the sheets are later separated, the inside surface is dull, and the outside surface is shiny. This difference in the finish has led to the perception that favouring a side has an effect when cooking. While many believe that the different properties keep heat out when wrapped with the shiny finish facing out, and keep heat in with the shiny finish facing inwards, the actual difference is imperceptible without instrumentation.The reflectivity of bright aluminium foil is 88% while dull embossed foil is about 80%.

We provide a full range of precision aluminum strip for almost any application. We produce aluminum strip in a wide variety of alloys, including clad composites. Our aluminum strip can be produced in standard dimensions or custom made to your special requirements. We produce both imperial and metric units. We manufacture in compliance with the main international specifications, and tighter tolerances or custom tempers are available upon request. We offer various surface conditions, custom finishes (painting, anodizing, embossing), special processing, and multiple packaging options to meet our customer's unique requirements. The following is a summary of our capabilities.

Manufactured in compliance with the main international specifications and standards, including: Aluminum Association, ASTM, EN, and DIN.

We can also manufacture in compliance with other international standards including:ASME, SAE, AMS, AWS, FED, MIL, QQ, ISO, BS, AFNOR, JIS and GOST.

Manufactured in compliance with the main international specifications and standards.

Tighter tolerances are available upon request.

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface. Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

Coal (from the Old English term col, which has meant "mineral of fossilized carbon" since the 13th century)is a combustible black or brownish-black sedimentary rock usually occurring in rock strata in layers or veins called coal beds or coal seams. The harder forms, such as anthracite coal, can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure. Coal is composed primarily of carbon along with variable quantities of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Throughout history, coal has been used as an energy resource, primarily burned for the production of electricity and/or heat, and is also used for industrial purposes, such as refining metals. A fossil fuel, coal forms when dead plant matter is converted into peat, which in turn is converted into lignite, then sub-bituminous coal, after that bituminous coal, and lastly anthracite. This involves biological and geological processes that take place over a long period. The Energy Information Administration estimates coal reserves at 948×109 short tons (860 Gt).One estimate for resources is 18 000 Gt.

Coal is the largest source of energy for the generation of electricity worldwide, as well as one of the largest worldwide anthropogenic sources of carbon dioxide releases. In 1999, world gross carbon dioxide emissions from coal usage were 8,666 million tonnes of carbon dioxide.In 2011, world gross emissions from coal usage were 14,416 million tonnes.Coal-fired electric power generation emits around 2,000 pounds of carbon dioxide for every megawatt-hour generated, which is almost double the approximately 1100 pounds of carbon dioxide released by a natural gas-fired electric plant per megawatt-hour generated. Because of this higher carbon efficiency of natural gas generation, as the market in the United States has changed to reduce coal and increase natural gas generation, carbon dioxide emissions have fallen. Those measured in the first quarter of 2012 were the lowest of any recorded for the first quarter of any year since 1992.In 2013, the head of the UN climate agency advised that most of the world's coal reserves should be left in the ground to avoid catastrophic global warming.

Coal is extracted from the ground by coal mining, either underground by shaft mining, or at ground level by open pit mining extraction. Since 1983 the world top coal producer has been China.In 2011 China produced 3,520 million tonnes of coal – 49.5% of 7,695 million tonnes world coal production. In 2011 other large producers were United States (993 million tonnes), India (589), European Union (576) and Australia (416).[9] In 2010 the largest exporters were Australia with 328 million tonnes (27.1% of world coal export) and Indonesia with 316 million tonnes (26.1%),while the largest importers were Japan with 207 million tonnes (17.5% of world coal import), China with 195 million tonnes (16.6%) and South Korea with 126 million tonnes (10.7%).

- Q:i need to buy some dome shaped solid copper or other good conductor but i cant find any online or locally.Please add a list of the best conductorsThank you

- Best conductors in order (best conductivity first) are Silver, copper, gold, aluminum resistivity Ag 15.9e-9 Ω-m resistivity Cu 17.2e-9 Ω-m resistivity Au 22.14e-9 Ω-m resistivity Al 28.2e-9 Ω-m resistivity W 56e-9 Ω-m resistivity Zn 68e-9 Ω-m resistivity Fe 100e-9 Ω-m resistivity Pt 105e-9 Ω-m resistivity Nichrome 150e-8 Ω-m you need to find a machine shop that specializes in copper, if this dome is largeAnd you do say it is solidYou would have to start with a solid block of copper and machine it downVery expensivelook in the yellow pages under machine shopEdit, the other answers are assuming you want a dome made of sheet copperI assumed a solid dome, not hollowWhich is it? edit2: hollow, just get a sheet of copper of the thickness you want and hammer it on a wooden formIt might be easier if you started with a circle and cut wedges out, say 4 or morethen when you hammer it on the form, the missing sections would come together, and you could solder them together .

- Q:What kind of saw blades can be cut?

- Usually the tooth spacing in 15-25mm, according to the number of teeth of saw blade sawing the reasonable choice of the thickness of the material from the theory we hope saw as thin as possible in fact, one is a kind of consumption. The process sheet materials and manufacturing with hard alloy saw blade determines the thickness of the saw blade.

- Q:I BMX and recently my bars have been slipping a lotIve tightened the stem but they still slipHow can I make it stop without buying a new stem or new bars?

- you could try making a shim by cutting a strip of aluminium soft drink can with tin snipswrap it round the bars and retighten the stem over topmy singlespeed does the same thing sometimes but i just put up with itin my case there were originally gradations around the outside of the bars to provide traction and these have worn downideally i should get new parts but i like the old look.

- Q:also? then calcium chloride is white colour? does that mean calcium sulphate and calcium nitrate is white in color too? and what did u get when sodium hydroxide plus aluminium sulphate? when other metal hydroxides plus aluminium sulphate or aluminium chloride or aluminium nitrate?? is it white precipitate?

- aluminium chloride is white aluminium sulphate is white aluminium nitrate is white they are all white because neither the aluminum, or the negative ion have color... and neither do their combination have color, (some aluminum compounds have color, not these). some aluminum materials made with a different negative ion do have color. --------------- calcium chloride is white calcium sulphate is white calcium nitrate is white again , not because of calcium, but because neither calcium or the neg ion have color, neither do the combinations, some calcium materials made with a different negative ion do have color. ------------------ when small amounts of metal hydroxides are added to aluminium sulphate or aluminium chloride or aluminium nitrate ....they will produce a ppt of aluminum hydroxide, which sometimes it is so transparent that it is invisible in the water, however it is usually cloudy enough to look white. if a person continues to add hydroxide the ppt will react to form a soluble -1 ion of [Al(OH)4] , and so your ppt dissolves

- Q:How are aluminum coils inspected for quality control?

- Aluminum coils are inspected for quality control through a combination of visual inspections and various non-destructive testing methods. These measures ensure that the coils meet the required specifications and are free from any defects or flaws. Visual inspections involve trained personnel carefully examining the coils for surface defects such as scratches, dents, or any irregularities in shape or size. The inspectors also check for any signs of contamination, oxidation, or discoloration. Any abnormalities detected during this visual inspection are noted and addressed accordingly. In addition to visual inspections, non-destructive testing techniques are employed to evaluate the internal quality of the aluminum coils. One commonly used method is ultrasonic testing, where high-frequency sound waves are transmitted through the coils. The reflected sound waves are analyzed to identify any internal defects like voids, cracks, or delaminations. This technique allows for a thorough assessment of the coil's integrity without causing any damage to the material. Another non-destructive testing method used for quality control is eddy current testing. This technique involves inducing electrical currents in the coils and measuring the resulting magnetic fields. Any variations in the magnetic fields can indicate flaws or defects in the aluminum, such as cracks or inclusions. Eddy current testing is particularly effective in detecting surface defects and discontinuities. Furthermore, measurements of important physical properties like thickness, width, and flatness are taken to ensure they meet the required standards. This is typically done using specialized instruments such as micrometers, calipers, or laser scanners. Overall, the inspection of aluminum coils for quality control involves a combination of visual inspections and non-destructive testing techniques to ensure that the coils are free from defects, meet the required specifications, and are of high quality.

- Q:Ok it's hunting season in England at the moment and I was thinking about hunting with my bb guns and my friendsWe need to know how to hunt and what should we hunt.

- you should hunt squirrels and rabbitsyou could also probably hunt birds but idk about the laws in england about bird huntingif you find a fox you should shoot it because they're just pests and harm domestic animalsthey're illegal to kill in south carolina but i still kill them anywayon how to hunt you should wear jeans and a long sleeved shirt to protect against ticks and thornsyou'll be in a partially wooded area right? so find a comfortable place to sit for about an hour and waitif you have a salt block it would be a good idea to set it out where you can clearly see it but any animal that approaches it cant see youif you dont feel like sitting around walk quietly in the area and take slow footsteps to avoid startling any animalsif you see an animal you want to kill pretend to not notice it and keep walkingit will go about its business and you will be able to take a few more steps toward itthen you can shoot itabout the bb gunidk what kind of gun u got but mine is a winchester 1029 air rifle that has pellet speed of 1000 feet per secondthats fast enough to penetrate a deer skull and is therefore very dangerousalways have the safety on and always point your gun to the groundwhen u see an animal, take the safety off, point, shoot, and turn the safety back on.

- Q:I need to make a boat for a science projectI can only use three things.1One 5X5 cm of aluminum foil.2Straws(the cheap ones you find at restaurants in the paper.)3Hot glue.I need to find the best design possible for this boat to hold as much weight in pennies as possible.Thanks for your time in advance.

- NopeWax paper does not belong interior the ovenwhile you're making a pie shell, in simple terms forego the paper lining and positioned the weights on itbe useful to poke holes interior the crust so it may vent, and to make useful the crust is caught tight to the nicely suited of the pan so it does not fall all to products (undesirable very own journey there!)Parchment paper could be used interior the oven, in many cases as much as 4 hundred levels, yet wax paper can't through fact the wax will soften, the paper will probable seize hearth, and so onof direction, in case you cook dinner with parchment paper at even a somewhat greater temperature than that is meant to be at, it may singe as nicely(yet another very own journey interior the kitchen.)

- Q:What are the potential applications of laminated aluminum coils?

- Laminated aluminum coils have a wide range of potential applications. They can be used in industries such as electrical, automotive, aerospace, and construction. Some specific applications include electrical transformers, heat exchangers, automotive radiators, air conditioning systems, and architectural facades. The lamination process enhances the durability, heat and corrosion resistance, and electrical conductivity of the coils, making them suitable for various demanding environments and applications.

- Q:Grilling sweet corn.what is your favorite method to get the perfect taste/flavor?

- I pull back the husks and remove the silkThen soak in water for at least one hourRemove from water and, if you want, coat with butter or flavored butterPull the husks back up to cover the cornI then wrap the cobs in aluminum foil and cook for about 20 to 30 minutes away from the direct heat.

- Q:Can the displacement sensor be used for real-time measurement of the aluminum coil thickness?

- Yes, you can use two sensors to measure thickness, either contact sensor or laser sensor

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum product for corrugated

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords