Outdoor PVDF Color Coated Aluminum Framing Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

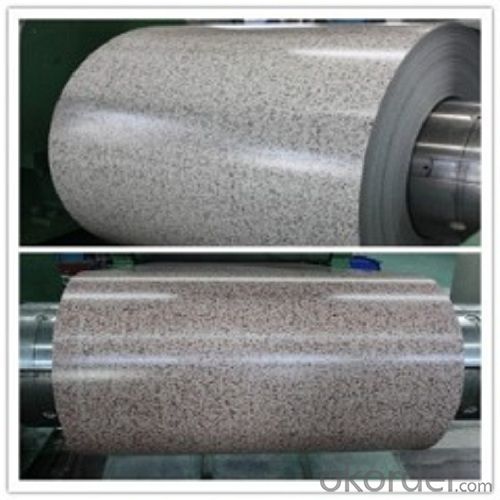

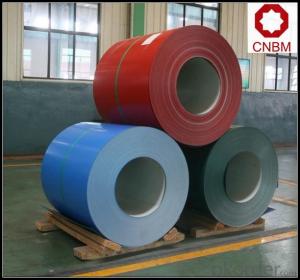

Colored aluminum coil, coating the color on the surface of the aluminum coil. There are 2 kind of paint

PE and PVDF, and are mainly used for aluminum composite panel, aluminum ceiling and aluminum roofing sheet etc. Good decorative ability make it more and more popular in all kinds of industries.

l Specifications of PVDF color coated aluminum coil used outdoors

1.Durable

2.easy processing

3.antirust and antiseptic

PVDF color coated aluminum coil used outdoors

1.Good quality with competitive price

2.Short delivery time

3.Easy processing

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advanc payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Color Coated Aluminum Coil is a popular product supplied by CNBM. And we are ready to meet any of your requirements.

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact us

Email:service@okorder.com

- Q: Are there any limitations to the coil weight of aluminum coils?

- Yes, there are limitations to the coil weight of aluminum coils. The weight of aluminum coils is typically limited by factors such as the capacity of the equipment used for transportation or processing, the strength and stability of the packaging materials, and the safety regulations imposed by the industry. Exceeding these limitations can lead to difficulties in handling, increased risk of damage or accidents, and may impact the overall efficiency of the manufacturing or distribution process.

- Q: What is virgin aluminum? I can't find anything about it, is it just another word for aluminum? Is there a difference?

- The word virgin means pure and free from any other metals but aluminium comes in a few different forms like stainless steel does so unless you know the originallity of pure aluminium I doubt if you will ever know Ask the person who is selling virgin aluminium he will instruct you how to find out what the difference is all metals come in different gauges so there must be some unanswered questions

- Q: Are aluminum coils suitable for gutter systems?

- Yes, aluminum coils are suitable for gutter systems. Aluminum is a popular choice for gutter systems due to its durability, lightweight nature, and resistance to rust and corrosion. It is a cost-effective option that can withstand harsh weather conditions and has a long lifespan. Additionally, aluminum coils are easy to install and maintain, making them an ideal choice for gutter systems.

- Q: Are there any restrictions on the coil length of aluminum coils?

- Yes, there are restrictions on the coil length of aluminum coils. The maximum coil length is typically determined by the capabilities of the equipment used for coil production and handling. Factors such as the size and capacity of coil winding machines, transportation and storage limitations, and the weight and stability of the coil itself all play a role in determining the maximum coil length. Additionally, longer coils may be more prone to handling and logistical issues, such as increased risk of damage during transportation or difficulties in uncoiling and processing. Therefore, it is important to consider these restrictions and limitations when determining the appropriate coil length for aluminum coils.

- Q: How are aluminum coils tested for thickness and flatness?

- Various methods are employed to test aluminum coils for thickness and flatness, ensuring they meet the necessary specifications. One commonly used method is non-destructive eddy current testing. This involves passing an alternating current through the coil and measuring the changes in the magnetic field caused by the eddy currents induced in the aluminum. By analyzing these changes, the thickness of the coil can be determined. Ultrasonic testing is also utilized to measure the thickness of aluminum coils. This method involves sending ultrasonic waves through the coil and measuring the time it takes for the waves to bounce back. It is highly accurate and capable of identifying any variations in thickness throughout the entire coil. To assess the flatness of aluminum coils, a straight edge or laser beam is often employed. The coil is placed on a flat surface, and the straight edge or laser beam is positioned across its surface. Any deviations from perfect flatness can be easily identified by observing the gaps or irregularities between the coil and the straight edge or laser beam. For a more comprehensive analysis of flatness, advanced technologies like laser profilometry can be used. This involves creating a three-dimensional map of the coil's surface, providing highly detailed information about any variations in flatness across its surface. In conclusion, aluminum coils are subjected to rigorous testing procedures to ensure they meet the necessary standards for thickness and flatness. These tests are essential in maintaining the quality and reliability of aluminum coils, particularly in applications where precision and consistency are crucial.

- Q: Can aluminum coils be used in solar thermal systems?

- Yes, aluminum coils can be used in solar thermal systems. Aluminum is a commonly used material for heat transfer in such systems due to its excellent thermal conductivity and corrosion resistance.

- Q: What are the different color options for anodized aluminum coils?

- An extensive array of color choices is available when it comes to anodized aluminum coils. To create a protective oxide layer on the surface, the aluminum is immersed in an electrolyte solution and an electric current is applied during the anodization process. This oxide layer can be dyed in various colors, providing customization and aesthetic improvement. Anodized aluminum coils come in popular colors such as silver, black, bronze, gold, copper, and champagne. These colors are achieved by using different dye solutions during the anodization process. Moreover, each color category offers a variety of shades and finishes, giving more versatility and options. The color possibilities for anodized aluminum coils are not limited to solid colors alone. By employing masking techniques or advanced printing technologies, it is also possible to create patterns, gradients, and even custom designs. This grants even more freedom for creativity and the ability to match specific branding or design requirements. What's more, anodized aluminum coils possess excellent color retention and durability. The anodized oxide layer not only shields against corrosion and wear but also acts as a foundation for the dyed color, resulting in long-lasting and vibrant finishes. To summarize, the range of color options for anodized aluminum coils is vast and varied, encompassing traditional metallic finishes as well as bold and unique shades. This assortment ensures limitless possibilities in architectural, industrial, and decorative applications, guaranteeing a suitable color option for any project.

- Q: This question asks for methods to clean an aluminum coil, which involves understanding the appropriate cleaning materials and techniques to avoid damaging the aluminum.

- <p>To clean an aluminum coil, start by using a soft cloth or sponge dampened with warm water and mild dish soap. Gently wipe the coil to remove dirt and grime. Avoid abrasive materials or harsh chemicals that could scratch the surface. After cleaning, rinse the coil thoroughly with clean water to remove any soap residue. Dry the coil completely to prevent water spots or corrosion. For stubborn stains, consider using a specialized aluminum cleaner, but always follow the manufacturer's instructions and test on a small area first.</p>

- Q: The user is asking if it's safe to use aluminum coil for food preparation in a microwave oven.

- <p>No, you should not use aluminum coil for food preparation in a microwave oven. Aluminum is a metal and can cause sparks or even a fire when exposed to the microwave's electromagnetic field. It can also reflect microwaves, potentially damaging the oven. Always use microwave-safe materials such as glass, ceramic, or microwave-safe plastic containers for food preparation in a microwave.</p>

- Q: I have a edelbrock aluminum intake that was sitting around for a year and it has some fading with a little corrosion. What's a good cleaner or chemical I can use to clean it up?

- I use Mother aluminum polish. It'll take a lot of patience and elbow grease but it works.

Send your message to us

Outdoor PVDF Color Coated Aluminum Framing Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords