7075 PE/PVDF Coated Aluminum Coils Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

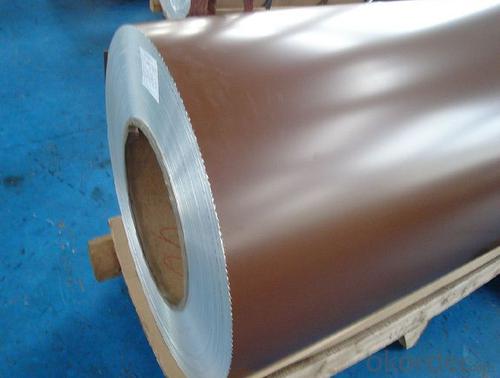

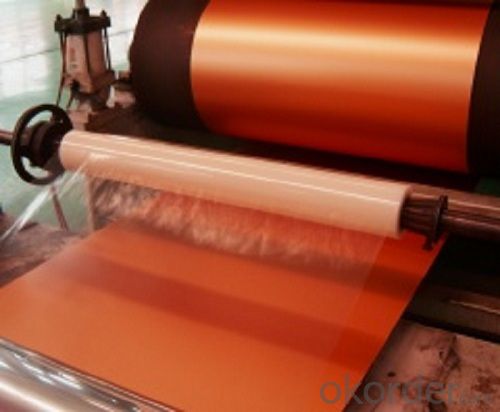

PE/PVDF Coated Aluminum Coil Mill Finish

l Product Introduction

Coated aluminum coils are widely applied to aluminum ceiling, roofing, fireproof roller shutter, doors, wall panel, facade cladding, etc.

l Product Specification:

| PE/PVDF coated aluminum coil | material 1060/3003/3004/3105 |

| painting Thickness | Single-coated ( 4-20 microns ); double-coated ( 25-28 micron ); 3 -coated ( 35-38 micron ) |

| width | within 1660mm |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Color coated aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What are the transportation and storage requirements for aluminum coils?

- The transportation and storage requirements for aluminum coils involve careful handling and protection. During transportation, coils should be securely strapped or loaded onto pallets to prevent damage or shifting. They should be transported using appropriate equipment, such as flatbed trucks, to avoid bending or distorting the coils. Additionally, coils should be stored in a clean, dry, and well-ventilated area to prevent corrosion. They should be stored horizontally, with proper support to avoid any deformation. Proper labeling and documentation are also necessary for tracking and identification purposes.

- Q: How much of a difference does it make? I recently bought a 700 SPS tactical in 308. It has the Houge pillar bedding stock. I love the tacky feeling rubber outside, but noticed that the fore end of the stock flexes a bit (enough to touch the free floating barrel.) I was wondering if the aluminum bedding block version of the same stock (or any other aluminum bedding stock) will be better? I know they cost more, and the experts claim they're great, but will an amateur shooter notice the difference? I like to target shoot, typically around 200 yards. BTW, I was also considering the Bell and Carlson medalist.

- Vote for the Aluminum yet somewhat might like a silver lined one bless by using a Catholic priest that emits holy water. That way in case they are additionally a vampire you nailed them.

- Q: aluminum welding

- Impossible. You need a TIG welder with AC and high frequency. Although you CAN use solid wire MIG with 100% argon shield gas, this is not a job for amateurs. MIG welding aluminum requires professional-grade equipment and several years experience with welding.

- Q: Can aluminum coils be used in the production of cryogenic storage tanks?

- Yes, aluminum coils can be used in the production of cryogenic storage tanks. Aluminum is a suitable material for cryogenic applications due to its low density, high thermal conductivity, and excellent corrosion resistance. These properties make it ideal for storing and transporting cryogenic liquids such as liquid nitrogen, oxygen, and argon. Aluminum coils can be used to fabricate the inner shell of the storage tank, providing a lightweight and durable solution. Additionally, aluminum is easily formable, allowing for the creation of complex tank shapes and designs. However, it is important to note that aluminum has a higher coefficient of thermal expansion compared to other materials like stainless steel, so proper design considerations must be taken to accommodate for thermal contraction and expansion during cryogenic operations.

- Q: What are the acoustic properties of buildings using aluminum coils?

- Various factors can influence the acoustic properties of buildings that utilize aluminum coils. These coils are commonly employed in the construction industry for purposes such as roofing, cladding, and insulation. In terms of acoustics, these properties can have both positive and negative effects on sound transmission within a building. One of the main advantages of using aluminum coils from an acoustic standpoint is their ability to act as a barrier that reflects sound waves. When installed correctly, they can help prevent sound from penetrating walls or ceilings, resulting in a reduction of external noise sources. This can be especially beneficial in areas with significant noise pollution, such as urban environments or locations near busy roads. Additionally, aluminum coils can contribute to the overall sound insulation of a building. Due to their material properties, they can provide a certain level of soundproofing, particularly when combined with other insulation materials. This can create a comfortable and quiet indoor environment, which can lead to improved concentration, productivity, and overall well-being for occupants. However, it is important to note that the acoustic properties of buildings using aluminum coils may also have limitations. Aluminum is a lightweight material compared to alternatives like concrete or brick, meaning it may not offer as much mass to block sound transmission. Therefore, in situations where high sound insulation is necessary, additional measures such as double glazing, acoustic seals, or thicker wall constructions may be required. Furthermore, the use of aluminum coils can also impact the sound reverberation within a space. Their smooth and reflective surface can cause sound waves to bounce off, resulting in increased echo and reverberation time. This can have a negative effect on speech intelligibility and acoustic comfort, particularly in larger open-plan areas or rooms with high ceilings. Overall, while aluminum coils can provide certain acoustic benefits such as sound reflection and insulation, it is crucial to consider the specific requirements of each building project. Consulting with acoustic engineers or professionals can help ensure that appropriate measures are taken to optimize the acoustic properties of buildings utilizing aluminum coils and address any potential limitations.

- Q: How are aluminum coils used in the production of musical instruments?

- Aluminum coils are widely used in the production of musical instruments due to their unique properties and advantages. One of the main uses of aluminum coils is in the manufacturing of guitar pickups. These coils are wound around a magnetic core and serve as the primary component for capturing the vibrations of the guitar strings and converting them into electrical signals. The electromagnetic properties of aluminum make it an excellent material for this purpose as it allows for the precise sensing and amplification of the instrument's sound. In addition to guitar pickups, aluminum coils are also utilized in the production of other instruments such as electric keyboards, synthesizers, and electric violins. These coils are essential for the generation and transmission of sound signals, ensuring high-quality audio output. Aluminum's lightweight nature makes it a preferred choice as it doesn't add unnecessary weight to the instrument, allowing for ease of handling and improved portability. Moreover, aluminum coils are employed in the construction of wind instruments like saxophones and trumpets. They are used to shape the tubing and create the body of these instruments. Aluminum's corrosion resistance properties are particularly valuable in this application, as it helps to maintain the instrument's durability and longevity. Overall, aluminum coils play a vital role in the production of musical instruments by providing a reliable means of capturing, transmitting, and amplifying sound signals. Their unique properties, such as electromagnetic sensitivity and corrosion resistance, make them an ideal choice for ensuring high-performance and longevity in various musical instruments.

- Q: Will the surface of the aluminum sheet touch the water?Aluminum rolls weighing 3.463 tons,.35mm thick, 900mm wide, very tight coil, is a mechanical binding. Water does not penetrate the surface of aluminium rolls

- Do you want to ask if the water has seeped into the crevice?If you get it soon, there should be no problem. No, you can just sun it and see if there's any water coming out of it

- Q: I'm ball milling aluminum into powder and I have filled the canister with some water to prevent the aluminum from igniting. The powder has begun to dissolve in the water. I'd like to know the best way to remove the dissolved aluminum from the water so I can get to the powder.There is around of cup of water in the canister, just to give an idea of the situation.

- Boil the water. The water will evaporate, leaving the aluminum behind.

- Q: Some manufactures (Kia, Hundai) use Iron blockswhileOther manufactures (Nissan, Chevy, ect.) use Aluminum blocks*****Is the point of using Iron blocks to increase long-term durability or temperature endurance??ORIs the use of Iron blocks simply an older, simpler technology (as compared to using Aluminum), the manufacture of which costs less money??And you would think that Aluminum weight savings would transer to better MPG, but the Kia gets very comparable mileage anyway.Thank you

- Aluminum's main advantages are weight and increased mpg for CAFE regulations. If you are going to keep your car to 150,000 miles eitheir block material will do. But if you are going to keep it 300,000 to the bitter, bitter end, you are better off with iron.

- Q: Explain how the temperature affects aluminum coil properties and behavior.

- <p>The relationship between aluminum coil and temperature is significant as temperature influences the coil's physical properties and performance. At lower temperatures, aluminum coils become more brittle and susceptible to cracking or breaking. As the temperature increases, aluminum's ductility improves, allowing it to be more easily shaped and formed. However, excessive heat can also lead to deformation and loss of strength. The thermal conductivity of aluminum is high, meaning it conducts heat well, which is useful in applications requiring heat transfer. Additionally, the electrical conductivity of aluminum is affected by temperature; as temperature rises, resistance increases, which can impact applications where electrical conductivity is critical.</p>

Send your message to us

7075 PE/PVDF Coated Aluminum Coils Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords