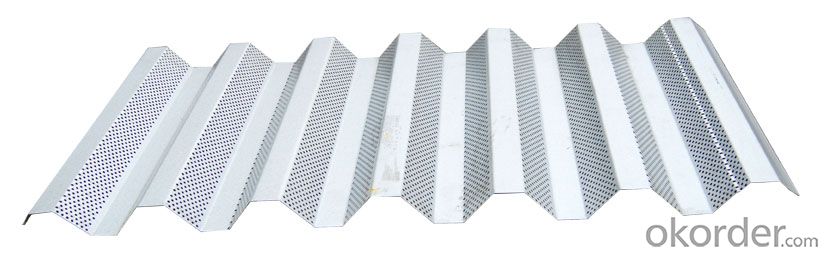

Color Corrugated Galvanized Steel Sheet corrugated color steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | Grade: | Place of Origin: | |||

| Brand Name: | Technique: | Surface Treatment: | |||

| Width: | Length: |

Packaging & Delivery

| Packaging Detail: | standard seaworthy packing |

| Delivery Detail: | 25 days |

Specifications

1.for civil building, car port, roofing, shelters, walk ways, fences & barns.

2. anti-rust.

3.good quality&service.

Color Galvanized Corrugated Steel Sheet

Typical size range

1.Thickness:0.17mm-1.0mm

2.Width:600mm-1250mm

3.Zinc coated:40g-275g

4.MOQ:25tons

Specifications

Color :RAL

Width before corrugation: 750, 900, 1000mm

Width after corrugation: 660, 800, 885mm

| Typical size range | 0.14 – 1.6mm Thick 650 – 1000mm Wide 1800 – 3600mm Length |

| Zinc coating | 20 to 180g/sqm |

| Spangle | Zero spangle, regular spangle, small spangle |

| Surface treatment | Chromate; oiling; phosphated; anti-finger print |

| Available specifications | EN 10326-2004 EN 10327-2004 JIS G3302 ASTM A653 A653M GB/T 2518-2004 |

| Steel grades | DX51D+Z; SGCC; A653 CS-B; DX53D; SGCH; SS GRADE80 |

- Q: What are the different sheet metal piercing techniques for steel sheets?

- There are several sheet metal piercing techniques that are commonly used for steel sheets. These techniques are utilized to create holes or openings in the steel sheets according to specific requirements. Here are some of the different piercing techniques: 1. Punching: Punching is a widely used technique where a punch and die set is used to create holes in the steel sheets. The punch is forced through the sheet, cutting out the desired shape or size of the hole. This technique is efficient and can be used for a variety of hole sizes and shapes. 2. Drilling: Drilling is another commonly used technique to pierce steel sheets. A drill bit is rotated at high speed, creating a hole in the sheet. Drilling is often used for smaller holes or when precision and accuracy are crucial. 3. Laser cutting: Laser cutting is a highly precise and versatile technique used to pierce steel sheets. A high-powered laser beam is focused on the sheet, melting and vaporizing the material to create holes or shapes. Laser cutting offers high-speed production and can create complex designs with great accuracy. 4. Notching: Notching is a technique used to create cutouts or grooves in steel sheets. It involves removing a portion of material from the edge or surface of the sheet, leaving behind a notch. Notching is often used to create tabs or slots that can be used for assembly purposes. 5. Stamping: Stamping is a technique where a die is pressed into the sheet metal to create a depression or raised feature. This method can be used to create holes, patterns, or embossed designs in the steel sheets. Stamping is commonly used for decorative or functional purposes. 6. Shearing: Shearing is a process where a sharp blade is used to cut through the steel sheet, creating a straight-edge hole. This technique is typically used for larger holes or straight-line cuts. These are just a few of the many sheet metal piercing techniques available for steel sheets. The choice of technique depends on factors such as the desired hole size, shape, precision, speed, and cost-effectiveness.

- Q: What are the different surface treatments for stainless steel sheets?

- Some common surface treatments for stainless steel sheets include brushed, mirror, and satin finishes. Brushed finishes create a textured look by using a fine abrasive material to brush the surface in one direction. Mirror finishes create a highly reflective surface by polishing the stainless steel to a mirror-like sheen. Satin finishes have a smooth, low-luster appearance and are achieved by using a fine abrasive material to create a consistent, non-reflective surface.

- Q: Are steel sheets resistant to water or moisture damage?

- Yes, steel sheets are generally resistant to water or moisture damage due to their non-porous nature. However, prolonged exposure to water or moisture can lead to corrosion over time if the steel is not properly protected or coated.

- Q: Can steel sheets be used in food processing or medical industries?

- Yes, steel sheets can be used in food processing and medical industries. Stainless steel sheets, in particular, are commonly used due to their excellent resistance to corrosion, hygiene properties, and durability. They meet the strict requirements of these industries, ensuring safe and sanitary processing environments.

- Q: What is the process of powder coating steel sheets?

- The process of powder coating steel sheets involves several steps. First, the steel sheets are cleaned and pre-treated to remove any dirt, grease, or rust. This is usually done through a combination of chemical cleaning and sandblasting. Next, the sheets are coated with a layer of electrostatically charged powder. The powder adheres to the steel sheets due to the opposite charges. After coating, the sheets are cured in an oven at high temperatures, typically around 400 degrees Fahrenheit. During this curing process, the powder melts and fuses onto the steel, creating a smooth and durable finish. Finally, the coated steel sheets are inspected for quality and packaged for shipping or further processing.

- Q: What is the weight of each steel sheet?

- The weight of each steel sheet depends on its dimensions and thickness. Steel sheets come in various sizes and thicknesses, so the weight can vary. To determine the weight, you would need to know the length, width, and thickness of the steel sheet. Once you have these measurements, you can use a weight calculator or reference a steel weight chart to find the weight per square meter or per square foot of the steel sheet. Multiplying this weight by the surface area of the sheet will give you the total weight of each steel sheet.

- Q: Are the steel sheets resistant to vibration or shock?

- Yes, steel sheets are generally resistant to vibration and shock. Steel is known for its high strength and durability, making it capable of withstanding external forces such as vibrations and shocks. The rigid nature of steel allows it to absorb and distribute the energy caused by vibrations or shocks, preventing any significant damage or deformation. Additionally, steel sheets are often used in applications where resistance to vibrations and shocks is crucial, such as in construction, automotive, and aerospace industries. However, it is important to note that the exact resistance of steel sheets to vibration or shock will depend on factors such as the thickness and quality of the steel used, as well as the specific magnitude and frequency of the vibrations or shocks.

- Q: Are the steel sheets easy to install?

- Indeed, the installation of steel sheets is generally a straightforward task. Their lightweight nature allows for easier handling and maneuverability throughout the installation procedure. Moreover, steel sheets often come equipped with pre-drilled holes or interlocking systems, which further streamlines the installation process. By employing the correct tools and possessing fundamental construction knowledge, individuals can effortlessly mount steel sheets onto diverse surfaces like roofs, walls, or fences. Nevertheless, it remains crucial to adhere to the manufacturer's instructions and safety guidelines to guarantee a correct and secure installation.

- Q: Can steel sheets be used for insulation?

- No, steel sheets cannot be used for insulation as they conduct heat and do not possess insulating properties.

- Q: Can steel sheets be used in food processing industries?

- Yes, steel sheets can be used in food processing industries. Stainless steel, in particular, is commonly utilized due to its corrosion resistance, durability, and ease of cleaning, making it suitable for various applications such as food storage, preparation surfaces, and equipment. Its non-reactive nature also ensures that it does not impart any undesirable flavors or contaminate the food being processed.

Send your message to us

Color Corrugated Galvanized Steel Sheet corrugated color steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords