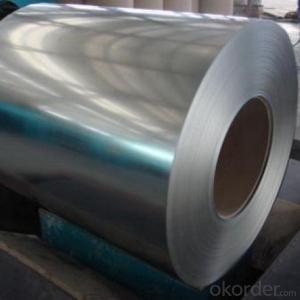

Steel Stainless 304 Steel Coils NO.1 Finish, Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

Details for products:

.

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers

- Q: Can stainless steel sheets be used for brewery tanks?

- Brewery tanks can indeed utilize stainless steel sheets. In the brewing industry, stainless steel is widely employed due to its exceptional resistance to corrosion, strength, and hygienic characteristics. It is a non-reactive material, meaning it does not interact with the beer or modify its flavor, consequently ensuring the purity and quality of the final product. By shaping and welding stainless steel sheets, tanks of various sizes and shapes can be created, making them suitable for a broad range of brewing applications. Moreover, stainless steel is effortless to clean, maintain, and sanitize, which is crucial for preserving the cleanliness and sterility of brewery tanks. In summary, stainless steel sheets are an ideal choice for brewery tanks due to their durability, chemical resistance, and hygienic properties.

- Q: Are stainless steel sheets suitable for food processing or medical applications?

- Yes, stainless steel sheets are highly suitable for both food processing and medical applications. Stainless steel is corrosion-resistant, durable, and easy to clean, making it ideal for environments where hygiene and cleanliness are crucial. It is also non-reactive with food or medical substances, ensuring that it does not contaminate or alter the properties of the materials it comes into contact with. Additionally, stainless steel's strength and resistance to extreme temperatures make it suitable for various processing and sterilization methods required in these industries.

- Q: Are stainless steel sheets resistant to hydrochloric acid?

- Yes, stainless steel sheets are generally resistant to hydrochloric acid.

- Q: Can stainless steel sheets be painted or coated?

- Yes, stainless steel sheets can be painted or coated. However, it is important to properly prepare the surface by cleaning and applying a suitable primer before painting or coating to ensure adhesion and durability of the finish.

- Q: What are the benefits of using embossed stainless steel sheets in elevator interiors?

- There are several benefits of using embossed stainless steel sheets in elevator interiors. Firstly, embossed stainless steel sheets add a touch of elegance and sophistication to the overall design of the elevator. The embossed patterns create a visually appealing surface that can enhance the aesthetic appeal of the interior space. This is especially important in commercial buildings and high-end residential complexes where a luxurious ambiance is desired. Secondly, embossed stainless steel sheets are highly durable and resistant to wear and tear. Elevator interiors are subject to constant use and can be prone to scratches, dents, and other damages. The embossed pattern on the stainless steel surface helps to hide minor imperfections, ensuring that the interior maintains its pristine appearance for a longer period of time. Additionally, stainless steel is known for its corrosion resistance, making it a suitable choice for environments with high humidity levels, such as elevator shafts. Furthermore, embossed stainless steel sheets are easy to clean and maintain. Elevator interiors are often exposed to dirt, fingerprints, and other stains. The smooth surface of the embossed stainless steel makes it easy to wipe away these marks, ensuring that the interior always looks clean and well-maintained. This is particularly important in public spaces where cleanliness is essential for creating a positive impression on users. Additionally, embossed stainless steel sheets offer a high level of customization. They can be manufactured in various patterns, textures, and finishes, allowing for endless design possibilities. This enables architects and designers to create unique and personalized elevator interiors that reflect the desired theme or branding of a building. The versatility of embossed stainless steel also makes it easy to match with other interior design elements, such as flooring, lighting fixtures, and wall coverings. In conclusion, the benefits of using embossed stainless steel sheets in elevator interiors include enhanced visual appeal, durability, ease of maintenance, and customization options. These qualities make embossed stainless steel an ideal material for elevators in various settings, from commercial buildings to residential complexes, adding value and elegance to the overall design.

- Q: Can stainless steel sheets be used for outdoor signage or billboards?

- Yes, stainless steel sheets can be used for outdoor signage or billboards. Stainless steel is a highly durable material that is resistant to corrosion, rust, and fading, making it ideal for outdoor applications. It can withstand harsh weather conditions, such as rain, snow, and UV exposure, without losing its integrity. Stainless steel sheets also offer a sleek and modern appearance, which can enhance the visual appeal of outdoor signage or billboards. Additionally, stainless steel can be easily fabricated and cut into various shapes and sizes, allowing for customization and creativity in design. Overall, stainless steel sheets are a reliable and long-lasting choice for outdoor signage or billboards.

- Q: What's the difference between cold rolling and hot rolling of stainless steel plate?

- Cold rolling and hot rolling are different processes, and cold rolling is usually made by longitudinal rolling. Cold rolling process usually includes preparation of raw materials, pickling, rolling, degreasing, annealing (heat treatment), finishing and so on. Cold rolling takes hot rolling product as raw material, and the raw material should be removed before cold rolling so as to ensure the surface cleanness of cold rolling products.

- Q: Are stainless steel sheets resistant to scaling at high temperatures?

- Stainless steel sheets, in general, possess resistance against scaling when exposed to high temperatures. This resistance is attributed to the elevated chromium content within stainless steel, which generates a protective oxide layer on the surface upon oxygen exposure. This oxide layer acts as a barrier, effectively hindering further oxidation and scaling of the material. Nevertheless, the extent of scaling resistance may fluctuate based on the particular grade and composition of stainless steel, as well as the temperature and duration of exposure. In exceedingly high-temperature surroundings, stainless steel might still encounter some degree of scaling; however, it typically exhibits greater resistance in comparison to alternative materials.

- Q: Can stainless steel sheets be used in outdoor applications?

- Certainly, outdoor applications can indeed make use of stainless steel sheets. Stainless steel, known for its exceptional resistance against corrosion and oxidation, proves to be a perfect option for outdoor purposes. It can endure challenging weather conditions, encompassing rainfall, snowfall, and even UV radiation, without undergoing rust or deterioration. Moreover, stainless steel exhibits impressive durability, allowing it to withstand heavy burdens and impacts, rendering it appropriate for a multitude of outdoor applications such as cladding, roofing, fencing, and decorative elements. Its attractiveness in terms of aesthetics and minimal upkeep needs further contribute to its popularity in outdoor usage.

- Q: What's the cheapest kind of stainless steel plate? What's the model and how much is it?

- The cheapest is 201, the price is relative to the thickness

Send your message to us

Steel Stainless 304 Steel Coils NO.1 Finish, Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords