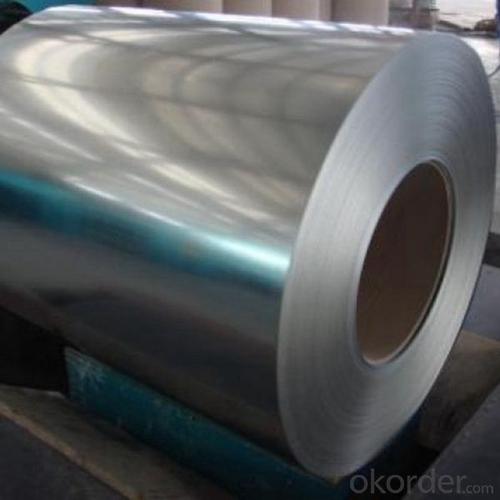

Steel Stainless 304 Steel Coils, Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

Details for products:

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be bent?

- Stainless steel sheets have the capability to be bent. This material, known for its versatility, can be molded into different forms and designs, including bends. The capacity to bend stainless steel sheets relies on their thickness and composition. Generally, thinner sheets are more pliable and easier to bend, whereas thicker sheets might necessitate specialized tools and techniques. It is crucial to bear in mind that the bending procedure could potentially weaken the strength and durability of the stainless steel sheet. Therefore, careful thought should be given to the particular application and requirements before embarking on the bending of stainless steel sheets.

- Q: 304 how can the water stain on the surface of stainless steel plate be formed?

- If you want to scrub the proposal as soon as possible processing, water Jiyue long more difficult to wear off, if it is ferrite, also easy to rust.

- Q: How do you prevent distortion when welding stainless steel sheets?

- To prevent distortion when welding stainless steel sheets, one must ensure proper heat control and minimize the amount of heat input. This can be achieved by using a lower welding current and speed, employing a proper welding technique, and utilizing preheating or post-welding heat treatment methods if necessary. Additionally, using clamps or fixtures to hold the sheets in place during welding and distributing the heat evenly across the joint can also help prevent distortion.

- Q: Are stainless steel sheets suitable for oil and gas applications?

- Yes, stainless steel sheets are highly suitable for oil and gas applications due to their superior corrosion resistance, high strength, and ability to withstand extreme temperatures and pressure conditions commonly found in the oil and gas industry. Additionally, stainless steel sheets offer excellent durability, easy maintenance, and long-lasting performance, making them an ideal choice for various equipment and structures used in oil and gas exploration, production, and processing.

- Q: What is the maximum temperature stainless steel sheets can withstand?

- The maximum temperature stainless steel sheets can withstand depends on the specific grade of stainless steel. Generally, most stainless steel grades can withstand temperatures up to around 1500°F (815°C) before experiencing significant oxidation or scaling. However, certain high-temperature grades of stainless steel, such as 310 or 321, can withstand temperatures up to 2100°F (1150°C) or even higher. It is important to consider the specific application and grade of stainless steel when determining the maximum temperature it can withstand to ensure optimal performance and durability.

- Q: Can stainless steel sheets be cut or shaped easily?

- Yes, stainless steel sheets can be cut or shaped easily. Stainless steel is known for its excellent machinability and workability, making it relatively easy to cut, shape, and form into desired shapes or sizes with the right tools and techniques.

- Q: How do you prevent warping of stainless steel sheets?

- There are several measures that can be taken to prevent warping of stainless steel sheets. These include: 1. Storage and handling: Stainless steel sheets should be stored in a clean and dry environment, away from moisture or excessive heat. It is important to handle the sheets carefully, avoiding any unnecessary bending or pressure that could cause warping. 2. Welding techniques: When welding stainless steel sheets, it is crucial to use the correct techniques and procedures. Proper heat control and weld placement can help minimize the risk of warping. Preheating the sheets before welding can also prevent distortion. 3. Stress relieving: This involves heating the stainless steel sheets to a specific temperature and then cooling them slowly. Stress relieving helps eliminate residual stresses that could lead to warping. 4. Support during machining: Proper support is important when machining stainless steel sheets to prevent warping. Clamps or fixtures can be used to securely hold the sheets in place. 5. Minimize heat exposure: It is important to avoid prolonged exposure to high temperatures during processes like cutting, grinding, or forming. Using coolants or lubricants during these processes can dissipate heat and minimize the risk of warping. 6. Choose the right grade and thickness: Selecting the appropriate grade and thickness of stainless steel sheets for a specific application is essential. Thicker sheets generally have more resistance to warping, while certain grades may be more prone to distortion. Consulting with a materials expert or engineer can help in selecting the right stainless steel sheets for a project. By implementing these preventive measures, the risk of warping stainless steel sheets can be significantly reduced, ensuring their integrity and longevity.

- Q: Are stainless steel sheets suitable for outdoor railings?

- Yes, stainless steel sheets are suitable for outdoor railings. Stainless steel is highly resistant to corrosion and has excellent durability, making it a popular choice for outdoor applications. It is also able to withstand harsh weather conditions, including rain, snow, and UV radiation, without losing its structural integrity or appearance. Stainless steel railings are low maintenance and easy to clean, making them a practical and long-lasting option for outdoor spaces. Additionally, stainless steel sheets offer a sleek and modern aesthetic, enhancing the overall look and feel of any outdoor railing system.

- Q: Are stainless steel sheets suitable for high-traffic areas?

- Yes, stainless steel sheets are highly suitable for high-traffic areas. They are durable, resistant to corrosion, and can withstand heavy use. Additionally, stainless steel sheets have a sleek and modern appearance, making them a popular choice for public spaces such as airports, hospitals, and commercial buildings.

- Q: What are the common manufacturing standards for stainless steel sheets?

- The common manufacturing standards for stainless steel sheets include ASTM A240, ASME SA240, EN 10028-7, and JIS G4304. These standards specify the chemical composition, mechanical properties, tolerances, and surface finishes required for stainless steel sheets used in various industries.

Send your message to us

Steel Stainless 304 Steel Coils, Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords