Hot Rolled Stainless Steel Coil 304 Standard: GB

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Coil:

Stainless steel coil is a production which not easy rust, acid resistance and corrosion resistance, Stainless steel coil is a new kind of Austenite stainless steel by used Mn, N replace Ni. so it is widely used in light industry, heavy industry, daily necessities and the decoration industry. Stainless steel coil has good corrosion resistance and hot / cold processing performance, instead of stainless steel products for used in the not high of corrosive environment, such as indoor, inland city outdoor etc.

2.Main Features of the Stainless steel coil:

1) High Quality: Using Latest automated control equipment to ensure the quality

2) Best Price: With most automated equipments to ensure our price is lower than the market

3) Fast Delivery: The delivery date within 20 das after get your order

4) Best Service: Our after-sell service team will help you to slove all the problems about the order

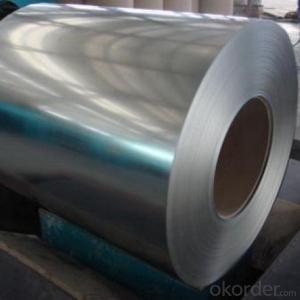

3. 304 Stainless steel coil Images

4. 304 Stainless steel coil Specification

Product name: 304 Stainless Steel Coil

Thickness: 0.2mm to 1.5mm

Technical: Cold Rolled

Width: 10mm to 1240mm

Type: 200 Series

Length: As customer's requested

Standard: JIS, SUS

Finish: BA, 2B, 8K, NO.3, NO.4, HL

MOQ: 100 MT

Ship Term: FOB Shenzhen port or CNF import port

Delivery Time: 15 to 20 day after the receive the deposit or LC

Packaging: By wooden pallet, wooden case or according to customer's request

5.FAQ

1) How about your company?

2) A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

3) How to guarantee the quality of the products?

4) We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5) How long can we receive the product after purchase?

6) In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can stainless steel sheets be used for fireplaces?

- Yes, stainless steel sheets can be used for fireplaces. Stainless steel is a popular material choice for fireplaces due to its high heat resistance and durability. It can withstand the high temperatures generated by the fire without warping or melting, making it a safe and reliable option. Stainless steel sheets can be used to construct the interior of the fireplace, including the firebox and chimney, or can be used as a decorative element on the façade of the fireplace. Additionally, stainless steel is resistant to corrosion and rust, ensuring that the fireplace will maintain its appearance over time.

- Q: Are stainless steel sheets suitable for architectural applications?

- Architectural applications greatly benefit from the suitability of stainless steel sheets. This material, known for its versatility and durability, offers numerous advantages for architectural projects. Its exceptional corrosion resistance makes it an ideal choice for outdoor applications exposed to harsh weather conditions. Additionally, stainless steel is easily cleaned and maintained, ensuring a visually appealing and long-lasting finish. Not only does stainless steel provide functional benefits, but it also enhances the architectural design with its aesthetic appeal. Its sleek and modern appearance can complement a variety of styles, ranging from contemporary to industrial. Architects have ample design flexibility as stainless steel can be fabricated into different shapes and sizes. Moreover, stainless steel sheets find extensive use in various architectural applications. They are commonly employed in cladding, roofing, and façade systems, adding a distinct and eye-catching element to buildings. Furthermore, stainless steel can be incorporated into interior design elements such as wall panels, handrails, and decorative finishes, creating a sophisticated and luxurious atmosphere. Overall, stainless steel's exceptional properties, combined with its aesthetic appeal and versatility, make it an excellent choice for architectural applications. Its durability, corrosion resistance, and ease of maintenance make stainless steel sheets a reliable and long-lasting option for architects and designers.

- Q: How to calculate the weight of stainless steel plate?

- There are usually only six kinds of steel related to the application of building construction. They all contain 17 to 22% chromium, and better steel also contains nickel. The addition of molybdenum can further improve atmospheric corrosion, especially for atmospheric corrosion resistant chlorides.

- Q: What are the common uses of stainless steel sheets in the food industry?

- Due to their numerous beneficial properties, stainless steel sheets find wide application in the food industry. Food processing equipment is a common use for these sheets in this industry. Machines like mixing tanks, conveyors, and food processing tables are fabricated using these sheets. The preference for stainless steel sheets in this regard is due to their resistance to corrosion, ease of cleaning, and non-reactivity with food substances, which ensures the safety and hygiene of the food. Another prevalent use of stainless steel sheets in the food industry is for food storage and transportation. Containers, tanks, and barrels used for storing and transporting food products are often manufactured using stainless steel sheets. The corrosion resistance of stainless steel guarantees the protection of the food from contamination and spoilage during storage and transportation. Kitchen equipment in the food industry also heavily relies on stainless steel sheets. Countertops, sinks, and cabinets are frequently made from these sheets because of their durability, heat resistance, and ease of cleaning. These qualities make stainless steel sheets ideal for use in food preparation areas where maintaining hygiene is of utmost importance. Furthermore, stainless steel sheets are utilized in the construction of food service equipment, such as ovens, grills, and refrigerators. These sheets play a crucial role in maintaining the desired temperature and preventing the growth of bacteria, ensuring that the food served is safe and of high quality. In conclusion, stainless steel sheets are widely used in the food industry for various purposes, including food processing equipment, food storage and transportation, kitchen equipment, and food service equipment. Their corrosion resistance, easy maintenance, and ability to uphold hygiene standards make them an ideal choice for various applications in the food industry.

- Q: What are the different finishes available for stainless steel sheets?

- There are several different finishes available for stainless steel sheets, each offering a unique look and level of protection. 1. No. 1 Finish: This is the most common and basic finish for stainless steel sheets. It is a hot-rolled finish that appears dull and rough, with visible grain lines. It is typically used for industrial applications where appearance is not a major concern. 2. No. 2B Finish: This is a bright, cold-rolled finish that is slightly reflective. It has a smooth surface with a matte finish and is commonly used for decorative purposes, such as in architectural applications or for kitchen appliances. 3. No. 4 Finish: Also known as brushed or satin finish, it has a fine polishing grit line that creates a distinctive look. This finish is often used for decorative applications, such as for elevator doors or trim, and can hide minor surface imperfections. 4. No. 8 Mirror Finish: This is the most reflective finish available for stainless steel sheets. It has a highly polished, mirror-like surface that is smooth and shiny. This finish is often used for decorative purposes, such as in architectural features or decorative trim. 5. Hairline Finish: This finish features a very fine, brushed texture that is similar to the grain of hair. It provides a subtle, elegant appearance and is commonly used for decorative and architectural applications. 6. Embossed Finish: This finish involves creating a pattern or design on the surface of the stainless steel sheet through embossing or stamping. It adds texture and visual interest to the sheet and is often used for decorative purposes. It is important to note that the availability of these finishes may vary depending on the supplier and the specific stainless steel grade being used.

- Q: Can stainless steel sheets be used for medical implants?

- Medical implants can indeed utilize stainless steel sheets. In the medical realm, stainless steel is frequently employed due to its remarkable resistance to corrosion, its strength, and its affordability. It is also biocompatible, meaning that it does not provoke any undesirable reactions when in contact with bodily tissues or fluids. To meet the distinct demands of medical implants, such as orthopedic plates, bone screws, dental implants, and cardiovascular stents, stainless steel sheets can be manufactured into a variety of shapes and sizes. Furthermore, stainless steel is easily cleanable and sterilizable, rendering it well-suited for implantation within the human body. However, it is important to note that different grades of stainless steel may possess varying attributes. As a result, it is crucial to choose the appropriate grade based on the specific application and requirements of the medical implant.

- Q: What are the different types of stainless steel sheet perforations available?

- There exists a variety of stainless steel sheet perforations, each possessing its own distinctive characteristics and applications. Among the most prevalent types are: 1. Round hole perforations: These perforations, characterized by evenly spaced round holes, are the simplest and most commonly employed. They ensure sufficient airflow and visibility. 2. Square hole perforations: Similar to their round counterparts, square hole perforations offer a distinct aesthetic and may be utilized for ventilation or decorative purposes. 3. Slotted perforations: Elongated in shape, slotted holes provide a larger open area compared to round or square holes. Consequently, they are often employed for drainage or filtering applications. 4. Hexagonal hole perforations: Hexagonal holes, featuring an exclusive pattern, are frequently used for architectural or decorative applications. They are also effective in facilitating airflow and visibility. 5. Decorative perforations: These perforations exhibit diverse shapes and designs, such as floral, geometric, or abstract patterns. Primarily employed for decorative purposes, they are commonly found in building facades or interior design. 6. Micro-perforations: These minute holes, typically less than 1mm in diameter, are utilized in applications necessitating high precision and fine filtration, like speaker grills or air diffusers. When selecting the appropriate perforation type, it is crucial to consider the specific requirements of your application. Factors such as open area, strength, visibility, and aesthetics must all be carefully evaluated to guarantee the most suitable choice for your specific needs.

- Q: Can stainless steel sheets be used for jewelry?

- Yes, stainless steel sheets can be used for jewelry. Stainless steel is a popular material choice in the jewelry industry due to its durability, resistance to rust and corrosion, and affordability. It is commonly used to create various types of jewelry, including rings, bracelets, earrings, necklaces, and pendants. Stainless steel sheets can be shaped, cut, and polished to create unique and stylish jewelry designs. Additionally, stainless steel jewelry is hypoallergenic, making it an excellent option for individuals with sensitive skin. Overall, stainless steel sheets are a versatile and practical material for creating beautiful and long-lasting jewelry pieces.

- Q: Can stainless steel sheets be used for chemical reactors?

- Indeed, chemical reactors can indeed utilize stainless steel sheets. The utilization of stainless steel in chemical reactors is quite popular due to its remarkable resistance to corrosion. Its ability to resist chemical reactions with various substances is commendable, thus rendering it suitable for handling corrosive chemicals or environments. Moreover, stainless steel sheets are renowned for their durability, exceptional strength, and capacity to endure high temperatures. Hence, they are ideal for deployment in chemical reactors that may operate under extreme conditions. Furthermore, stainless steel is effortlessly maintainable and easy to clean, which is a pivotal factor in ensuring the purity and integrity of the reaction process. In conclusion, stainless steel sheets are widely employed in the construction of chemical reactors and are widely recognized as a trustworthy and efficient choice of material for this purpose.

- Q: What is the stainless steel grid board? What areas of stainless steel mesh panels are used in?

- Lattice plate of stainless steel steel has strong corrosion resistance, anti-corrosion effect was significantly higher than that of hot dip galvanized steel plate, but the cost is higher, stainless steel grid board is widely used in municipal, environmental protection, steel structure, boiler, desulfurization and denitrification projects, procurement of stainless steel grid plate, Changzhou Gemeirui steel grid plate.

Send your message to us

Hot Rolled Stainless Steel Coil 304 Standard: GB

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords