Cold Rolled Hot Rolled ASTM 316 201 304 Stainless Steel Sheets

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

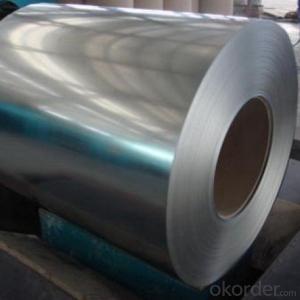

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can stainless steel sheets be used for cladding?

- Yes, stainless steel sheets can be used for cladding. Stainless steel is a popular choice for cladding due to its durability, corrosion resistance, and aesthetic appeal. It is commonly used in exterior cladding applications for buildings, such as facades, canopies, and curtain walls. Stainless steel sheets provide a sleek and modern appearance while offering protection against harsh environmental conditions. Additionally, stainless steel cladding is low maintenance, long-lasting, and can be easily cleaned, making it a practical choice for both residential and commercial applications.

- Q: What are the main chemical constituents of stainless steel plates?

- Stainless steel not only refers to a stainless steel, but more than one hundred kinds of industrial stainless steel, the development of each kind of stainless steel in its specific application areas have good performance. The key to success is to find out what the purpose is, and then determine the correct type of steel. There are usually only six kinds of steel related to the application of building construction. They all contain 17 to 22% chromium, and better steel also contains nickel. The addition of molybdenum can further improve atmospheric corrosion, especially for atmospheric corrosion resistant chlorides.

- Q: Are stainless steel sheets resistant to saltwater?

- Yes, stainless steel sheets are resistant to saltwater. Stainless steel is known for its corrosion resistance, and it is particularly well-suited for environments with high levels of saltwater exposure. The chromium content in stainless steel forms a protective layer on the surface of the metal, preventing rust and corrosion. This makes stainless steel sheets an excellent choice for applications in marine environments, such as boat construction, offshore structures, and coastal infrastructure. Additionally, stainless steel's resistance to saltwater also makes it suitable for other applications like coastal architecture, kitchen equipment, and medical instruments.

- Q: Can stainless steel sheets be used for medical sterilization equipment?

- Certainly, medical sterilization equipment can indeed utilize stainless steel sheets. Due to its exceptional resistance to corrosion, impressive heat resistance, and remarkable durability, stainless steel stands as a favored material choice within the medical industry. These remarkable attributes render stainless steel sheets perfectly suited for a wide array of medical applications, including the construction of sterilization equipment. With the ability to endure high temperatures and endure multiple sterilization cycles without warping or deteriorating, stainless steel sheets prove themselves suitable for autoclaves and other sterilization devices. Moreover, stainless steel's effortless cleaning and maintenance capabilities play a critical role in preventing the proliferation of bacteria and other harmful microorganisms. As a result, stainless steel sheets find widespread usage in medical settings where the presence of sterilization equipment is imperative.

- Q: What is the electrical resistance of stainless steel sheets?

- The electrical resistance of stainless steel sheets can vary depending on factors such as the grade of stainless steel, its thickness, and the temperature at which it is being used. However, in general, stainless steel is considered to have a relatively high electrical resistance compared to other metals.

- Q: What are the different types of edge finishes available for stainless steel sheets?

- There are several different types of edge finishes available for stainless steel sheets. These finishes are applied to the edges of the sheets to provide a clean and polished appearance, as well as to protect against sharp edges and potential corrosion. 1. Mill Finish: This is the standard edge finish for stainless steel sheets. It is the raw, untreated edge that is produced during the manufacturing process. While it may have a slightly rough or uneven appearance, it is still functional and commonly used for industrial applications. 2. Deburred Edges: In order to remove any sharp or jagged edges, the stainless steel sheet can be deburred. This is done by grinding or sanding down the edges to create a smoother and safer finish. Deburred edges are commonly used in applications where safety is a concern, such as in food processing or medical equipment. 3. Rounded Edges: Rounded edges are created by using a rounding tool to smooth out the sharp corners of the stainless steel sheet. This type of edge finish not only enhances the aesthetics of the sheet, but also reduces the risk of injury from sharp edges. Rounded edges are often preferred for architectural or decorative applications. 4. Beveled Edges: Beveled edges are achieved by cutting or grinding the edge of the stainless steel sheet at a specific angle, typically 45 degrees. This creates a chamfered edge that adds a sleek and modern look to the sheet. Beveled edges are commonly used in applications where aesthetics and design are important, such as in furniture or interior design. 5. Polished Edges: Polished edges involve buffing or polishing the edge of the stainless steel sheet to create a smooth and mirror-like finish. This type of edge finish adds a touch of elegance and sophistication to the sheet, making it suitable for high-end architectural or decorative applications. In summary, the different types of edge finishes available for stainless steel sheets include mill finish, deburred edges, rounded edges, beveled edges, and polished edges. Each finish offers its own unique benefits and is chosen based on the specific requirements of the application.

- Q: Can stainless steel sheets be used for outdoor signage or billboards?

- Yes, stainless steel sheets can be used for outdoor signage or billboards. Stainless steel is highly durable, weather-resistant, and corrosion-resistant, making it an excellent material choice for outdoor applications. It can withstand harsh weather conditions, including rain, snow, and UV exposure, without deteriorating or fading. Additionally, stainless steel sheets can be easily fabricated and customized to create visually appealing and long-lasting outdoor signage or billboards.

- Q: What are the different types of perforated finishes available for stainless steel sheets?

- Stainless steel sheets offer a range of perforated finishes, each with its own distinct appearance and functionality. The most widely used finish is the round hole, which features evenly spaced circular perforations, providing a sleek, contemporary look. For a more simplistic yet noticeable finish, the square hole is a popular choice. Like the round hole, it has evenly spaced perforations, but in a square shape. Another option is the slotted hole finish, which offers elongated holes that can be either straight or staggered. This finish is often chosen for its decorative appeal and ability to enhance ventilation. For a visually captivating pattern, the hexagonal hole finish is an excellent choice. With its six-sided holes, it creates a modern and eye-catching design, making it ideal for architectural applications. In addition to the standard hole shapes, stainless steel sheets can also be perforated with decorative patterns. These patterns can range from floral designs to abstract shapes, allowing for a personalized and unique finish. When selecting a perforated finish for stainless steel sheets, it is crucial to consider factors such as the desired appearance, functional requirements, and the specific application. By taking these factors into account, one can choose the perfect perforated finish to meet their needs.

- Q: What are the standard dimensions for stainless steel sheets?

- The dimensions of stainless steel sheets differ based on the type and grade of stainless steel utilized. Nevertheless, there exist some widely available common sizes in the market. Typically, the standard width for most stainless steel sheets falls within the range of 36 to 48 inches, while the length can vary between 72 to 120 inches. These dimensions are commonly employed in construction, automotive, and manufacturing applications. The thickness of stainless steel sheets can also vary, with common choices ranging from 0.024 to 0.1875 inches. Thinner sheets are often used for decorative or lightweight purposes, whereas thicker sheets are utilized for heavy-duty applications requiring enhanced strength and durability. It is essential to note that these dimensions are general guidelines and may differ depending on specific project requirements. Moreover, custom sizes can be manufactured to meet the unique needs of a particular application. Overall, the standard dimensions for stainless steel sheets provide a range of options suitable for diverse industries and purposes. This ensures flexibility in selecting the appropriate size for a specific project.

- Q: What is the price range for stainless steel sheets?

- The price range for stainless steel sheets can vary depending on a few factors such as the thickness, size, and grade of the stainless steel. Generally, the price range for stainless steel sheets starts at around $30 per square foot for thinner sheets and can go up to $150 per square foot for thicker or higher-grade sheets. It's important to note that prices can also be influenced by market conditions and supplier pricing policies, so it's always a good idea to compare prices from different suppliers before making a purchase.

Send your message to us

Cold Rolled Hot Rolled ASTM 316 201 304 Stainless Steel Sheets

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords