Hot Rolled Stainless Steel NO.1 Finish Grade 316L

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

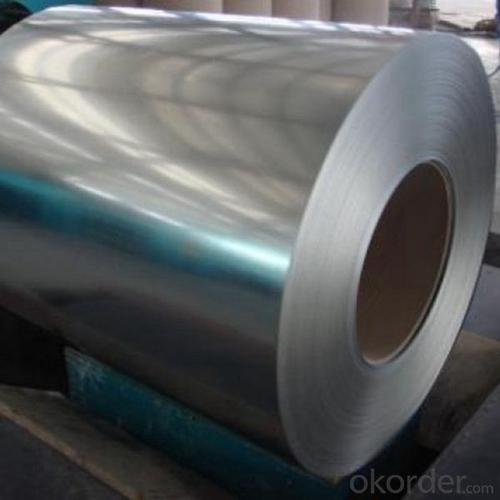

Products Description for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheet

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Do stainless steel sheets have a warranty?

- Yes, stainless steel sheets generally come with a warranty. The duration and terms of the warranty may vary depending on the manufacturer and the specific product. It is always recommended to check with the supplier or manufacturer for the details of the warranty coverage. Typically, the warranty covers defects in material or workmanship and provides a replacement or repair of the stainless steel sheet if any issues arise within the specified warranty period. It is important to follow the manufacturer's care and maintenance instructions to ensure the validity of the warranty.

- Q: Can stainless steel sheets be used for roofing applications?

- Indeed, roofing applications can make use of stainless steel sheets. This material, stainless steel, possesses durability and resistance against corrosion, rendering it appropriate for outdoor environments. Its strength, longevity, and aesthetic appeal make it a popular choice in architectural settings, particularly for roofing purposes. Stainless steel roofing sheets come in various thicknesses and profiles, allowing for flexibility in design. Furthermore, as it is fire-resistant and capable of withstanding harsh weather conditions, stainless steel proves to be a dependable option for roofs.

- Q: What is the maximum temperature stainless steel sheets can withstand?

- The maximum temperature that stainless steel sheets can typically withstand is around 1500-1650°F (815-900°C). However, it is important to note that this temperature limit can vary depending on the specific grade and composition of the stainless steel.

- Q: How do I prevent pitting on stainless steel sheets?

- To prevent pitting on stainless steel sheets, it is important to keep them clean and dry. Avoid exposure to harsh chemicals or high chloride environments, as they can cause corrosion. Regularly inspect the sheets for any signs of damage or pitting, and promptly address any issues. Applying a protective coating or using stainless steel cleaners can also help to prevent pitting and maintain the appearance and integrity of the sheets.

- Q: Are stainless steel sheets suitable for power plant equipment?

- Yes, stainless steel sheets are highly suitable for power plant equipment. Stainless steel is known for its exceptional corrosion resistance, high strength, and durability, making it an ideal material for various applications in power plants. It can withstand high temperatures, pressure, and chemical exposure commonly found in power generation environments. Additionally, stainless steel's hygienic properties, ease of maintenance, and long lifespan make it a preferred choice for power plant equipment.

- Q: What is the thickness tolerance for stainless steel sheets?

- The thickness tolerance for stainless steel sheets can vary depending on the specific grade and manufacturing process. However, in general, the typical thickness tolerance for stainless steel sheets is around +/- 0.005 inches or +/- 0.13 millimeters.

- Q: What is the function of a stainless steel plate at the top of the steel chimney?

- At present, the commonly used classification methods are classified according to the characteristics of the steel structure, the chemical composition of steel and the combination of the two. Generally divided into martensitic stainless steel, ferritic stainless steel, austenitic stainless steel, duplex stainless steel and precipitation hardening stainless steel, etc., or divided into chromium, stainless steel and nickel stainless steel two categories.

- Q: How do you prevent chloride-induced corrosion in stainless steel sheets?

- There are various steps that can be taken to prevent corrosion in stainless steel sheets caused by chloride. These include: 1. Selecting the appropriate stainless steel grade that is resistant to chloride corrosion. Grades like 316 or 317 are particularly effective in resisting chloride attack. 2. Enhancing the resistance to chloride-induced corrosion by applying a passivation treatment to the stainless steel sheets. This treatment eliminates any surface iron contamination that might have occurred during fabrication and restores the protective oxide layer. 3. Ensuring proper cleaning of the stainless steel sheets on a regular basis to eliminate any chloride-containing contaminants that might have accumulated on the surface. It is important to maintain a clean surface as chloride ions can accumulate from sources like saltwater or cleaning products. 4. Minimizing contact with substances that contain chloride to significantly reduce the risk of corrosion. This involves avoiding direct contact with saltwater, cleaning agents that contain chloride, as well as chloride-rich environments such as swimming pools or coastal areas. 5. Taking design considerations into account in environments where chloride exposure is expected. This can involve using protective coatings, minimizing crevices or gaps where chlorides can accumulate, and ensuring proper drainage to prevent stagnant conditions. 6. Regularly inspecting and maintaining the stainless steel sheets to identify and address any potential corrosion issues before they worsen. This may include repairing surface damage, reapplying passivation treatments if necessary, and keeping the surface clean. By following these preventive measures, the risk of chloride-induced corrosion in stainless steel sheets can be significantly reduced, ensuring their long-term durability and performance.

- Q: Can stainless steel sheets be used for storage racks?

- Yes, stainless steel sheets can be used for storage racks. Stainless steel is a durable and corrosion-resistant material, making it suitable for storing various items. It also has a high load-bearing capacity, making it ideal for heavy-duty storage applications.

- Q: How do you remove water spots from stainless steel sheets?

- To remove water spots from stainless steel sheets, you can mix equal parts vinegar and water in a spray bottle and spray the affected areas. Let it sit for a few minutes, then wipe it off with a soft cloth. Additionally, you can use a stainless steel cleaner or polish specifically designed for removing water spots.

Send your message to us

Hot Rolled Stainless Steel NO.1 Finish Grade 316L

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords