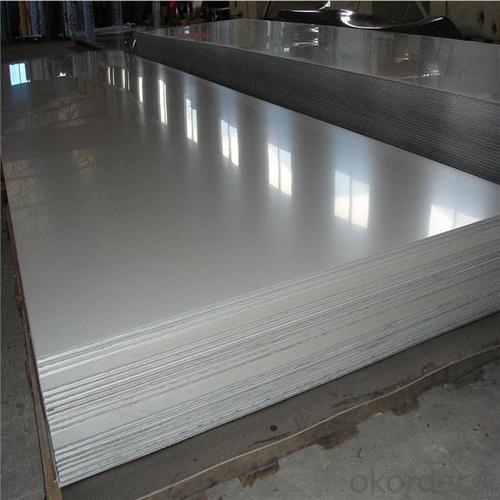

1mm 0.8mm thick 4x8 aisi 304 Stainless Steel Sheet Price Per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

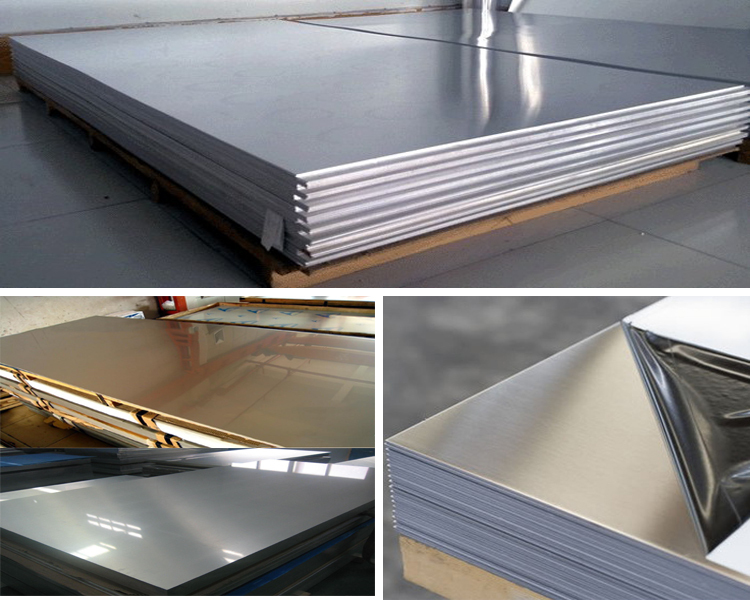

Product | Stainless steel sheet/plate |

Grade | 304 |

Material | Refined raw material |

Standard | JIS\AISI\ASTM\GB\DIN\EN\Other |

Thickness | 0.25mm~~3.0mm |

Length | According to the requirements |

Width | 15mm~~1500mm |

Technology | Cold rolled |

Surface | BA\2B\No.4\No.8\HL\8K\Brush\Titanium \Etching\Embossed |

Vickers hardness | 304:HV160-HV190 |

Certification | ISO |

Place of origin | Guangdong,China(mainland) |

Edge | Mill edge or slit edge |

Package | According to the requirements |

Grade | Ni | Cr | Cu | C | Mn | Si | P | S | Origin |

201 high cu | 1.271 | 14.58 | 1.436 | 0.078 | 9.478 | 0.369 | 0.394 | 0.0064 | Baosteel |

201 half cu | 1.118 | 13.419 | 0.897 | 0.083 | 10.376 | 0.366 | 0.0349 | 0.0084 | Baosteel |

304 | 8.1 | 18.22 | / | 0.043 | 1.06 | 0.47 | 0.037 | 0.005 | Baosteel |

410 | 0.08 | 12.22 | / | 0.02 | 0.26 | 0.29 | 0.013 | 0.02 | Baosteezl |

Packaging & Shipping

In order to prevent the damage from transit, our finished products are packaged carefully with steel pallets or wooden pallets. It could go directly into the production or out to the customers as finished products.

Company Information

Who we are?

1, We concentrate on offering stainless steel coils/sheets/strips/circles with

good quality and best service.

2, We also offer slitting, shearing, BA/NO.4/Hair line,8K processing, colored

processing, etching embossed and other processing services.

3,Until now , we have exported stainlesssteel material to following

countries: Vietnam, Thailand, Turkey, Russia,Maroc, Korea ,India,Pakistan,

UAE ,Ukraine and so on.

- Q: Can stainless steel sheets be used for power generation equipment?

- Yes, stainless steel sheets can be used for power generation equipment. Stainless steel is a versatile material that offers several beneficial properties for power generation applications. It has excellent corrosion resistance, which is crucial in environments where the equipment is exposed to water, steam, or other corrosive substances. Stainless steel also has high strength and durability, making it suitable for withstanding the high temperatures and pressures typically found in power generation systems. Additionally, stainless steel is a good conductor of electricity, making it suitable for electrical components and connections within the equipment. Therefore, stainless steel sheets are commonly used in the construction of power generation equipment such as turbines, boilers, heat exchangers, and exhaust systems.

- Q: Can stainless steel sheets be recycled?

- Indeed, it is possible to recycle stainless steel sheets. Stainless steel, a material known for its high recyclability, boasts one of the most impressive recycling rates compared to other materials. Once stainless steel sheets have served their purpose, they can be gathered and transported to a recycling facility. The recycling procedure entails melting down the stainless steel sheets and reshaping them into fresh products, all while preserving their original properties and quality. This renders stainless steel an eco-friendly and sustainable material option. Additionally, recycling stainless steel aids in the preservation of natural resources, diminishes energy usage, and reduces waste.

- Q: Can stainless steel sheets be used for storage containers?

- Yes, stainless steel sheets can be used for storage containers. Stainless steel is a durable and corrosion-resistant material, making it suitable for storing various items safely and maintaining their integrity.

- Q: What are the color options for stainless steel sheets?

- Stainless steel sheets generally come in a variety of color options, depending on the specific type of finish applied to the surface. The most common color options for stainless steel sheets include silver, which is the natural color of stainless steel, as well as black, gold, bronze, and copper. These colors are achieved through processes such as powder coating, PVD coating, or chemical treatments, which create a thin layer on the surface of the stainless steel sheet. The color options allow for greater versatility in design and can be chosen to complement different aesthetics and applications.

- Q: Are stainless steel sheets resistant to abrasion?

- Yes, stainless steel sheets are generally resistant to abrasion. Stainless steel is known for its high strength and durability, making it less prone to scratches and wear compared to other materials. It has a smooth surface that can withstand friction and abrasion, making it suitable for various applications where resistance to scratches and wear is required. However, it is important to note that the level of resistance can vary depending on the specific grade and finish of stainless steel used.

- Q: Can stainless steel sheets be used for air conditioning systems?

- Indeed, air conditioning systems can utilize stainless steel sheets. Stainless steel, renowned for its toughness, corrosion resistance, and impressive strength, is a favored material option for various components within air conditioning systems. Specifically, it finds frequent usage in air conditioning ducts, air handling units, heat exchangers, and other components that encounter air or moisture. The stainless steel sheets employed in air conditioning systems usually adhere to a specific grade that suits the intended purpose, thereby guaranteeing peak performance and longevity. All in all, stainless steel sheets represent a dependable and effective selection for air conditioning systems.

- Q: Can stainless steel sheets be used for countertops?

- Yes, stainless steel sheets can be used for countertops. Stainless steel is a durable and versatile material that is resistant to stains, heat, and bacteria, making it an excellent choice for kitchen countertops. It is easy to clean, maintain, and has a sleek and modern appearance. Stainless steel countertops are commonly used in commercial kitchens but are also becoming increasingly popular in residential settings due to their durability and hygienic properties.

- Q: Can stainless steel sheets be used in decorative applications?

- Yes, stainless steel sheets can be used in decorative applications. Due to their durability, versatility, and attractive appearance, stainless steel sheets are commonly used in interior and exterior design projects, such as wall cladding, decorative panels, countertops, backsplashes, and furniture. They offer a sleek and modern aesthetic while also being resistant to corrosion, making them suitable for both functional and decorative purposes.

- Q: What are the different types of edge finishes available for stainless steel sheets?

- There are several different types of edge finishes available for stainless steel sheets. These finishes are applied to the edges of the sheets to provide a clean and polished appearance, as well as to protect against sharp edges and potential corrosion. 1. Mill Finish: This is the standard edge finish for stainless steel sheets. It is the raw, untreated edge that is produced during the manufacturing process. While it may have a slightly rough or uneven appearance, it is still functional and commonly used for industrial applications. 2. Deburred Edges: In order to remove any sharp or jagged edges, the stainless steel sheet can be deburred. This is done by grinding or sanding down the edges to create a smoother and safer finish. Deburred edges are commonly used in applications where safety is a concern, such as in food processing or medical equipment. 3. Rounded Edges: Rounded edges are created by using a rounding tool to smooth out the sharp corners of the stainless steel sheet. This type of edge finish not only enhances the aesthetics of the sheet, but also reduces the risk of injury from sharp edges. Rounded edges are often preferred for architectural or decorative applications. 4. Beveled Edges: Beveled edges are achieved by cutting or grinding the edge of the stainless steel sheet at a specific angle, typically 45 degrees. This creates a chamfered edge that adds a sleek and modern look to the sheet. Beveled edges are commonly used in applications where aesthetics and design are important, such as in furniture or interior design. 5. Polished Edges: Polished edges involve buffing or polishing the edge of the stainless steel sheet to create a smooth and mirror-like finish. This type of edge finish adds a touch of elegance and sophistication to the sheet, making it suitable for high-end architectural or decorative applications. In summary, the different types of edge finishes available for stainless steel sheets include mill finish, deburred edges, rounded edges, beveled edges, and polished edges. Each finish offers its own unique benefits and is chosen based on the specific requirements of the application.

- Q: What are the common methods of cutting stainless steel sheets?

- There are several common methods of cutting stainless steel sheets, each with its own advantages and limitations. Here are a few commonly used methods: 1. Shearing: Shearing involves using a machine with two blades to slice through the stainless steel sheet. This method is suitable for thinner sheets and produces clean, straight cuts. However, it may leave a slight burr on the edge of the cut. 2. Plasma cutting: Plasma cutting is a versatile method that uses a high-temperature plasma arc to melt and blow away the metal. It is effective for cutting stainless steel sheets of various thicknesses and shapes. Plasma cutting provides fast, precise cuts and can handle both straight and curved lines. 3. Laser cutting: Laser cutting uses a focused laser beam to cut through stainless steel sheets. It is highly accurate and produces smooth, precise cuts with minimal distortion. Laser cutting is suitable for both thin and thick sheets, but it can be slower than other methods for thicker materials. 4. Waterjet cutting: Waterjet cutting involves using a high-pressure stream of water mixed with abrasive particles to cut through stainless steel. This method is precise and can handle various thicknesses and shapes. Waterjet cutting is known for its clean edges and the ability to cut without heat-affected zones. However, it may be slower than other methods and can be more expensive. 5. Sawing: Sawing is a traditional method that involves using a saw blade to cut through stainless steel sheets. It is suitable for thicker sheets and can handle both straight and curved cuts. Sawing produces relatively clean cuts but may result in more material waste compared to other methods. These are just a few of the common methods used to cut stainless steel sheets. The choice of method depends on factors such as the thickness of the sheet, desired cut quality, shape complexity, and budget. It is important to consider the specific requirements of the project and consult with professionals to determine the most suitable cutting method.

Send your message to us

1mm 0.8mm thick 4x8 aisi 304 Stainless Steel Sheet Price Per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords