1mm Thickness Stainless Steel Sheet Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 45000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

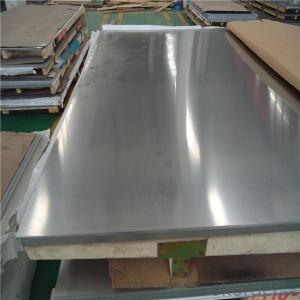

1mm Thickness Stainless Steel Sheet Prices

Product Description

1mm Thickness Stainless Steel Sheet Prices

Technology | Cold Rolled |

Thickness | 0.14 mm – 2.0 mm (tolerances ±0.02 mm) |

Width | 10.0 mm – 1240 mm (tolerances ±0.02 mm) |

Processing | Pickling / Straighten / Flatten / Leveling |

Grade | 201 |

Edge | Mill Edge / Slitting Edge |

Annealed | Full hardness to Deep drawing quality (DDQ) |

Surface | BA - processed with bright heat treatment after cold rolling. |

2B - after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | |

2D – matt finish, best choice for deep drawing | |

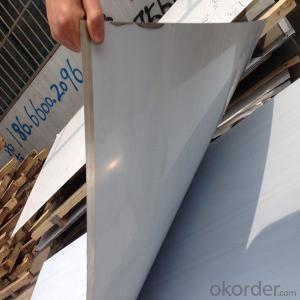

Protection | 1. Inter paper available |

2. PVC protecting film available | |

All standard products are supplied without inter paper & PVC film. If needed, please inform. | |

Product Show

Trade & Market

Factory Information

| Factory Size (Sq.meters): | Above 100,000 square meters | |

| Factory Location: | Luogu Industrial Zone, Dainan Town, Xinghua City, Jiangsu Province. China | |

| Number of Production Lines: | Above 10 | |

| Number of R&D Staff: | 11 - 20 People | |

| Number of QC Staff: | 21 - 30 People | |

| Contract Manufacturing: | Design Service Offered Buyer Label Offered |

- Q: What are the different types of stainless steel sheet surface textures for decorative purposes?

- There are several types of stainless steel sheet surface textures that are commonly used for decorative purposes. These textures can enhance the overall aesthetic appeal of the stainless steel sheet and make it suitable for various applications. Some of the different types of stainless steel sheet surface textures include: 1. Brushed Finish: This texture is achieved by rubbing the stainless steel sheet surface with a fine abrasive material, resulting in a uniform satin-like appearance. Brushed finish is popular for its smooth and subtle texture, making it suitable for various decorative applications. 2. Mirror Finish: Also known as a highly reflective finish, the mirror finish is achieved by polishing the stainless steel sheet surface to a high gloss. This texture creates a mirror-like reflection and is often used in decorative applications where a sleek and modern appearance is desired. 3. Bead Blast Finish: This texture is created by blasting the stainless steel sheet surface with small glass beads, resulting in a matte and textured appearance. Bead blast finish is commonly used in decorative applications where a non-reflective and textured surface is desired. 4. Embossed Finish: This texture involves creating patterns or designs on the stainless steel sheet surface by stamping or pressing it with a patterned roller or plate. Embossed finishes can vary in pattern and depth, adding a visually appealing and tactile element to the stainless steel sheet. 5. Etched Finish: This texture is achieved by chemically etching the stainless steel sheet surface with an acid or other corrosive substances. Etched finishes can create various designs, patterns, or even images on the surface, making it ideal for decorative applications where intricate detailing is required. 6. Hairline Finish: This texture is created by mechanically polishing the stainless steel sheet surface with fine abrasive belts or brushes, resulting in a narrow and uniform textured pattern. Hairline finishes are commonly used in decorative applications where a subtle and elegant appearance is desired. These are just a few examples of the different types of stainless steel sheet surface textures available for decorative purposes. Each texture offers a unique visual and tactile quality, allowing for a wide range of design options when using stainless steel sheets for decorative applications.

- Q: Can stainless steel sheets be used in outdoor environments?

- Stainless steel sheets are indeed applicable for outdoor settings. Given their exceptional resistance to corrosion, stainless steel proves to be an ideal material for outdoor uses. It can endure tough weather conditions like rain, sunlight, and temperature changes without any degradation. Moreover, stainless steel is resistant to rust, staining, and oxidation, which further amplifies its appropriateness for outdoor utilization. Consequently, stainless steel sheets have garnered widespread popularity in a range of outdoor applications such as construction, architecture, signage, and outdoor furniture.

- Q: Are stainless steel sheets suitable for outdoor sculptures or decorative pieces?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or decorative pieces. Stainless steel is a durable and corrosion-resistant material, making it ideal for withstanding harsh outdoor conditions. It is resistant to rust, corrosion, and staining, which allows it to maintain its aesthetic appeal over time. Additionally, stainless steel sheets can be easily manipulated and welded into various shapes and forms, enabling artists to create intricate and detailed sculptures or decorative pieces. Moreover, stainless steel has a sleek and modern appearance that can enhance the overall beauty of outdoor spaces. Overall, stainless steel sheets are an excellent choice for outdoor sculptures or decorative pieces due to their durability, resistance to corrosion, and aesthetic appeal.

- Q: Can stainless steel sheets be used for pharmaceutical equipment?

- Indeed, pharmaceutical equipment can utilize stainless steel sheets. Stainless steel is highly favored in the pharmaceutical industry due to its remarkable resistance to corrosion, durability, and ease of cleaning. It does not react with other substances and does not emit any detrimental substances that could compromise the quality or purity of pharmaceutical products. Stainless steel sheets can be molded into different forms and sizes to cater to the specific needs of pharmaceutical equipment, including storage tanks, mixing vessels, sterilization devices, and piping systems. Additionally, the sleek surface of stainless steel hinders the buildup of bacteria, rendering it an exceptionally sanitary option for pharmaceutical applications.

- Q: What are the different methods of cutting stainless steel sheets?

- There are several methods available for cutting stainless steel sheets, depending on the specific requirements and desired precision. 1. Shearing: This is one of the most common methods used for cutting stainless steel sheets. It involves using a shearing machine with sharp blades to cut through the material. Shearing is ideal for straight cuts and is relatively fast and cost-effective. 2. Laser cutting: Laser cutting is a highly precise method that uses a high-powered laser beam to cut through stainless steel sheets. It provides a clean and smooth cut, and can be used to create intricate designs or complex shapes. Laser cutting is widely used in industries that require high precision and quality finishes. 3. Plasma cutting: Plasma cutting uses a high-temperature plasma arc to melt through stainless steel sheets. This method is suitable for cutting thick stainless steel sheets or materials with high conductivity. Plasma cutting offers fast cutting speeds and can handle various shapes and thicknesses. 4. Waterjet cutting: Waterjet cutting involves using a high-pressure jet of water mixed with abrasive particles to cut through stainless steel sheets. This method is highly versatile and can create complex shapes with high precision. Waterjet cutting is also a cold cutting process, which means it does not produce heat-affected zones or alter the material's structure. 5. Abrasive cutting: This method uses an abrasive wheel or disc to grind and cut through stainless steel sheets. It is commonly used for rough cuts or in situations where other methods are not feasible. Abrasive cutting can be done manually or with the help of power tools, such as angle grinders. Each of these cutting methods has its own advantages and limitations, and the choice of method depends on factors such as the thickness of the stainless steel sheet, desired precision, budget, and production requirements.

- Q: Can stainless steel sheets be used in medical applications?

- Certainly, medical applications can indeed utilize stainless steel sheets. The medical sector favors stainless steel for its remarkable resistance against corrosion, its durability, and its simplicity when it comes to sterilization. It finds extensive employment in medical devices, surgical instruments, and implantable components, as it can endure rigorous sterilization procedures like autoclaving. This capability is pivotal in upholding cleanliness and averting infections. Moreover, stainless steel is biocompatible, signifying that it does not interact negatively with bodily tissues or induce any harm or adverse responses. All in all, stainless steel sheets are an unwavering and adaptable material suitable for a plethora of medical applications.

- Q: Can stainless steel sheets be used for HVAC systems?

- Yes, stainless steel sheets can be used for HVAC systems. Stainless steel is highly resistant to corrosion and can withstand high temperatures, making it an ideal material for HVAC components such as ductwork, heat exchangers, and exhaust systems. It is also durable and easy to clean, ensuring long-lasting performance in HVAC applications.

- Q: What are the different types of edges available for stainless steel sheets?

- There are several different types of edges available for stainless steel sheets, each with its own specific purpose and aesthetic appeal. Here are some of the common edge types: 1. Mill Edge: This is the standard edge finish produced by the mill, which is often considered the most cost-effective option. It has a relatively smooth, unfinished appearance. 2. Slit Edge: This edge is achieved by cutting the stainless steel sheet along its length, resulting in a straight edge with slight burrs. It is commonly used for thinner gauges of stainless steel. 3. Deburred Edge: This edge is created by removing any burrs or sharp edges from the slit edge, resulting in a smoother finish that is safer to handle. It is commonly used in applications where safety is a concern, such as food processing or medical equipment. 4. Rounded Edge: This edge is achieved by rounding off the sharp corners of the stainless steel sheet. It provides a more aesthetically pleasing look and also improves safety by eliminating sharp edges. 5. Beveled Edge: This edge is created by cutting a diagonal bevel along the edge of the stainless steel sheet. It is often used for decorative purposes and can add a touch of elegance to the finished product. 6. Rolled Edge: This edge is formed by rolling the stainless steel sheet under high pressure, resulting in a smooth, curved edge. It is commonly used in applications where a seamless look is desired, such as architectural projects or automotive components. Overall, the choice of edge type for stainless steel sheets depends on the specific requirements of the application, including functionality, safety, and aesthetics. It is important to consider these factors in order to select the most suitable edge type for the desired end use.

- Q: Lead and stainless steel plate welding together? How do you solder it?

- Lead and stainless steel, two different metal elements. Although the welding process is difficult, it can still be welded together.

- Q: What are the applications of stainless steel sheets in the automotive industry?

- Stainless steel sheets are widely used in the automotive industry due to their numerous beneficial properties. These sheets find applications in various components and parts of automobiles, contributing to the overall performance, durability, and aesthetics of vehicles. One of the key applications of stainless steel sheets in the automotive industry is in the production of exhaust systems. Stainless steel is highly resistant to corrosion and heat, making it an ideal material for exhaust pipes. These sheets can withstand the high temperatures generated by the engine, ensuring longevity and reliability of the exhaust system. Additionally, stainless steel sheets are used in the manufacturing of automotive body panels. They provide excellent strength and rigidity, allowing for the production of lightweight yet sturdy body parts. Stainless steel's resistance to corrosion is also advantageous, as it ensures that the body panels do not degrade over time, even in harsh weather conditions. Furthermore, stainless steel sheets are employed in the production of fuel tanks and other fluid storage components. Stainless steel's corrosion resistance and ability to withstand high pressure make it a suitable material for these applications. The use of stainless steel in fuel tanks ensures that they remain leak-free and durable, leading to enhanced safety and longevity. Moreover, stainless steel sheets are utilized in the production of various interior and exterior trim parts. These include decorative elements such as grilles, trims, and accents, which enhance the aesthetics of the vehicle. Stainless steel's ability to be polished and finished to a high shine adds a touch of elegance and sophistication to the car's design. In summary, stainless steel sheets have numerous applications in the automotive industry. They are used in exhaust systems, body panels, fuel tanks, and trim parts, among others. The exceptional properties of stainless steel, such as corrosion resistance, heat resistance, and strength, contribute to the overall performance, durability, and aesthetics of automobiles.

Send your message to us

1mm Thickness Stainless Steel Sheet Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 45000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords