201/304/316L Stainless Steel Sheets Elevator Decorative Sheets Made In China

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

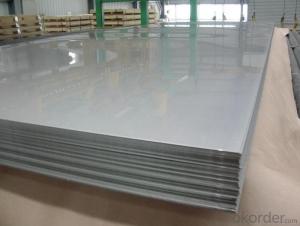

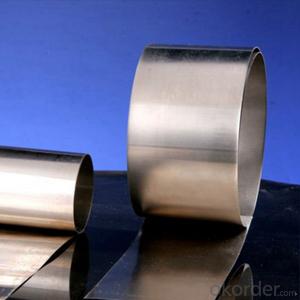

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

ITEM | DESCRIPTION |

Commodity | Stainless Steel Coil |

Material | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430, etc. |

Surface | 2B, BA, 8K, No. 4 No.1 |

Standard | AISI, ASTM, DIN, EN, GB, JIS, etc. |

Specification | 1. Thickness : 0.3mm -120mm |

Application | 1. Automotive: Automotive trim and molding/Difficult-to-form exhaust-system |

Process | Hot rolled / cold rolled |

Payment | L/C,T/T |

MOQ | 20 Ton |

Productivity | 700 tons per month. |

Package | Standard seaworthy export packing or according to the customers' request. |

Delivery Time | It is based on the order, normally within 30 days after receiving your advance payment. |

Note | We can produce other standard as the customers' requirement. |

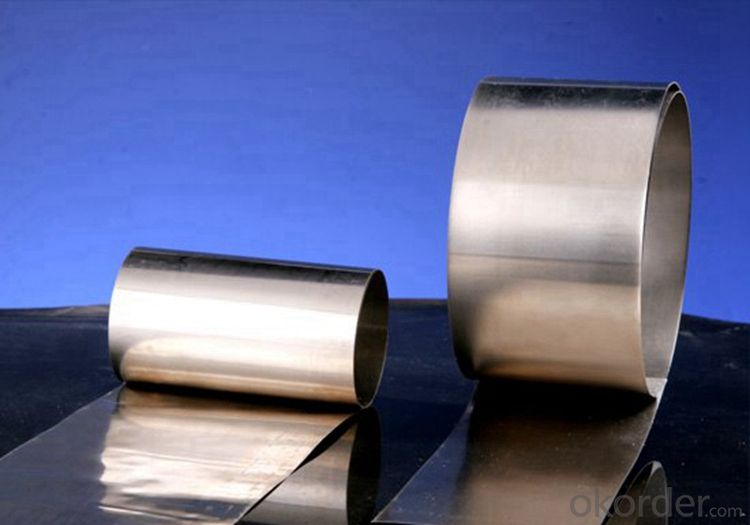

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can stainless steel sheets be recycled?

- Yes, stainless steel sheets can be recycled. Stainless steel is a highly recyclable material, and its recycling rate is one of the highest among all materials. When stainless steel sheets reach the end of their useful life, they can be collected and sent to a recycling facility. The recycling process involves melting down the stainless steel sheets and reforming them into new products, without losing their properties or quality. This makes stainless steel a sustainable and environmentally friendly material choice. Recycling stainless steel also helps to conserve natural resources, reduce energy consumption, and minimize waste.

- Q: How do you remove fingerprints from brushed stainless steel sheets?

- These simple steps can be followed to remove fingerprints from brushed stainless steel sheets: 1. Gather the necessary cleaning supplies, including a microfiber cloth, mild dish soap, warm water, and either a stainless steel cleaner or vinegar. 2. Dampen the microfiber cloth with warm water, ensuring that it is slightly damp but not soaking wet. 3. Carefully wipe the stainless steel surface in the direction of the grain, always following the grain to prevent scratches or streaks. 4. If the fingerprints persist, add a small amount of mild dish soap to the damp cloth and continue wiping the surface. Rinse the cloth thoroughly after applying the soap. 5. If the fingerprints are still visible, utilize a stainless steel cleaner specifically designed for brushed surfaces. Apply a small amount of the cleaner onto the microfiber cloth and wipe the surface in the direction of the grain. Adhere to the manufacturer's instructions for the particular cleaner being used. 6. As an alternative, employ white vinegar as a natural cleaning solution. Dampen a cloth with vinegar and gently wipe the surface in the direction of the grain. Vinegar is effective in removing fingerprints and restoring shine. 7. After successfully removing the fingerprints, use a dry microfiber cloth to gently buff the surface. This will eliminate any remaining streaks and provide the stainless steel with a polished finish. Always test any cleaning solution on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. Avoid using abrasive materials or cleaners containing chlorine or bleach, as they can harm the brushed finish of the stainless steel.

- Q: Can stainless steel sheets be used for water filtration?

- Yes, stainless steel sheets can be used for water filtration. Stainless steel is known for its corrosion resistance and durability, making it suitable for various applications including water filtration systems. The sheets can be used as filters or screens to remove impurities and contaminants from water, ensuring cleaner and safer drinking water.

- Q: What are the common methods of cutting stainless steel sheets?

- Cutting stainless steel sheets can be done using various methods, each with its own advantages and limitations. Let's take a look at a few commonly employed techniques: 1. Shearing: When using shearing, a machine with two blades is utilized to effortlessly slice through the stainless steel sheet. This technique is ideal for thinner sheets and delivers clean, straight cuts. However, there is a possibility of a slight burr on the cut edge. 2. Plasma cutting: Plasma cutting is a versatile approach that harnesses a high-temperature plasma arc to melt and remove the metal. This method is effective for cutting stainless steel sheets of different thicknesses and shapes. It offers speedy and precise cuts, accommodating both straight and curved lines. 3. Laser cutting: Laser cutting relies on a focused laser beam to effectively slice through stainless steel sheets. It is known for its high level of accuracy, generating smooth and precise cuts with minimal distortion. Laser cutting is suitable for thin and thick sheets but may be slower than other methods when dealing with thicker materials. 4. Waterjet cutting: Waterjet cutting employs a high-pressure stream of water mixed with abrasive particles to carve through stainless steel. This technique is renowned for its precision and ability to handle varying thicknesses and shapes. Waterjet cutting produces clean edges and avoids heat-affected zones. However, it may be slower and more costly compared to other methods. 5. Sawing: Sawing is a traditional method that employs a saw blade to cut through stainless steel sheets. It is most suitable for thicker sheets and can handle both straight and curved cuts. Sawing yields relatively clean cuts, although it may result in more material waste compared to other techniques. These are just a few examples of the common methods employed to cut stainless steel sheets. The choice of method depends on factors such as sheet thickness, desired cut quality, shape complexity, and budget. It is crucial to consider the specific requirements of the project and seek professional advice to determine the most suitable cutting method.

- Q: How do stainless steel sheets compare to other materials?

- Stainless steel sheets have several advantages over other materials, making them a popular choice in various industries. Firstly, stainless steel is known for its exceptional durability and strength. It can withstand high temperatures, pressure, and corrosion, making it suitable for a wide range of applications. This durability ensures a longer lifespan and reduces the need for frequent replacements, saving both time and money. Secondly, stainless steel sheets have excellent resistance to corrosion and rust. This property is particularly important in environments with high humidity or exposure to chemicals, as it prevents degradation and maintains the integrity of the material. Other materials, such as aluminum or carbon steel, may require protective coatings or regular maintenance to achieve similar levels of corrosion resistance. Furthermore, stainless steel sheets have a clean and smooth surface finish, making them aesthetically pleasing and easy to clean. This quality is crucial in industries such as food processing, pharmaceuticals, and healthcare, where hygiene and cleanliness are paramount. Stainless steel sheets also offer versatility in terms of fabrication and customization. They can be easily formed, welded, and shaped into different sizes and configurations, allowing for a wide range of applications. This versatility makes stainless steel sheets suitable for architectural, automotive, and industrial uses. Lastly, stainless steel is environmentally friendly. It is 100% recyclable, meaning that it can be melted down and reused without any loss in quality or performance. This recyclability reduces the demand for new materials and lessens the environmental impact associated with manufacturing processes. In summary, stainless steel sheets outperform other materials in terms of durability, corrosion resistance, cleanliness, versatility, and environmental sustainability. These qualities make stainless steel sheets a superior choice for various industries and applications.

- Q: Are stainless steel sheets resistant to hydrogen embrittlement?

- Yes, stainless steel sheets are generally resistant to hydrogen embrittlement. Hydrogen embrittlement is a phenomenon that occurs when hydrogen atoms diffuse into the metal structure, causing it to become brittle and prone to cracking. However, stainless steel has a high resistance to hydrogen embrittlement due to its unique composition and microstructure. The presence of chromium in stainless steel forms a protective oxide layer on the surface, which acts as a barrier to prevent hydrogen diffusion into the metal. Additionally, stainless steel sheets are often alloyed with other elements such as nickel and molybdenum, which further enhance their resistance to hydrogen embrittlement. However, it is important to note that certain conditions, such as exposure to high temperatures or high levels of hydrogen, can still potentially lead to hydrogen embrittlement in stainless steel. Therefore, it is crucial to consider the specific application and operating conditions when determining the suitability of stainless steel sheets in relation to hydrogen embrittlement.

- Q: Can stainless steel sheets be used for cryogenic storage containers?

- Indeed, cryogenic storage containers can make use of stainless steel sheets. Stainless steel is renowned for its exceptional strength, durability, and corrosion resistance, making it perfectly suitable for cryogenic purposes. Moreover, stainless steel exhibits low thermal conductivity, effectively reducing heat transfer from the environment to the stored contents. This particular characteristic is vital in cryogenic storage as it helps maintain the necessary low temperatures for preserving materials like liquefied gases or biological samples. In summary, stainless steel sheets serve as a dependable and widely employed material for cryogenic storage containers.

- Q: Can stainless steel sheets be used in outdoor applications?

- Certainly, outdoor applications can indeed make use of stainless steel sheets. Stainless steel, known for its exceptional resistance against corrosion and oxidation, proves to be a perfect option for outdoor purposes. It can endure challenging weather conditions, encompassing rainfall, snowfall, and even UV radiation, without undergoing rust or deterioration. Moreover, stainless steel exhibits impressive durability, allowing it to withstand heavy burdens and impacts, rendering it appropriate for a multitude of outdoor applications such as cladding, roofing, fencing, and decorative elements. Its attractiveness in terms of aesthetics and minimal upkeep needs further contribute to its popularity in outdoor usage.

- Q: Can stainless steel sheets be used for signage?

- Yes, stainless steel sheets can be used for signage. Stainless steel is a durable and long-lasting material that is resistant to corrosion, making it suitable for both indoor and outdoor signage. It has a sleek and modern appearance, which makes it a popular choice for various types of signage, including company logos, directional signs, nameplates, and even large outdoor billboards. Stainless steel sheets can be easily cut, engraved, or laser-etched to create customized designs and text, allowing for a wide range of creative options. Additionally, stainless steel signage is often chosen for its ability to withstand harsh weather conditions, UV rays, and vandalism, ensuring that the signage remains intact and legible for many years.

- Q: What's the cheapest kind of stainless steel plate? What's the model and how much is it?

- The cheapest is 201, the price is relative to the thickness

Send your message to us

201/304/316L Stainless Steel Sheets Elevator Decorative Sheets Made In China

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords