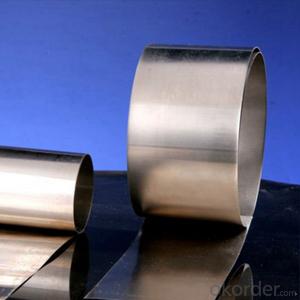

Stainless Steel ASTM A240m 201/304/316L Stainless Steel Coil for Kitchen Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

Technical Notes:

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Detailed Picture for Stainless Steel Coils/Sheets:

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Are stainless steel sheets suitable for outdoor sculptures?

- Indeed, outdoor sculptures greatly benefit from the use of stainless steel sheets. This material is renowned for its durability and resistance to corrosion, making it exceptionally well-suited for enduring the harsh conditions of the outdoors. Furthermore, stainless steel exhibits remarkable resistance to rust, staining, and fading, thereby establishing itself as a low-maintenance alternative for outdoor sculptures. Moreover, stainless steel boasts a sleek and contemporary appearance, effectively enhancing the aesthetic allure of outdoor artworks. Its robustness and pliability also render it ideal for crafting intricate and elaborate sculptures. Consequently, stainless steel sheets prove to be an outstanding selection for outdoor sculptures, guaranteeing their longevity while simultaneously amplifying their visual impact.

- Q: What is the average lifespan of stainless steel sheets?

- The lifespan of stainless steel sheets can vary depending on factors such as the grade and quality of the stainless steel, the environment in which it is used, and the level of maintenance and care it receives. In general, stainless steel sheets are renowned for their durability and long-lasting nature. They are specifically engineered to withstand corrosion, rust, and other forms of degradation, making them suitable for a wide array of applications. Under ideal conditions and with adequate maintenance, stainless steel sheets can endure for several decades or even longer. However, in harsher environments that expose them to aggressive chemicals, extreme temperatures, or high levels of moisture, their lifespan may be shortened. To ensure the longevity of stainless steel sheets, it is crucial to engage in regular cleaning, proper storage, and routine inspections. By adhering to recommended maintenance practices, stainless steel sheets can deliver reliable performance and endure for an extended period.

- Q: What are the different surface finishes available for stainless steel sheets?

- Some of the different surface finishes available for stainless steel sheets include brushed, mirror, satin, and embossed finishes. These finishes can provide different aesthetic appearances and textures to suit various applications and design preferences.

- Q: What are the different types of stainless steel sheet surface coatings available?

- There are several different types of stainless steel sheet surface coatings available, each offering unique properties and benefits. Some of the most common types include: 1. No Coating: Stainless steel sheets without any coating have a natural, smooth surface finish. This type is often used in applications where corrosion resistance is a primary concern. 2. Brushed Finish: This coating creates a distinctive brushed pattern on the stainless steel surface. It provides a decorative appearance while also hiding scratches and fingerprints. 3. Mirror Finish: A mirror coating gives stainless steel sheets a highly reflective surface, similar to a mirror. This type is popular in architectural and decorative applications. 4. Satin Finish: Satin coatings offer a smooth, matte appearance with a low reflectivity. They are frequently used in high-end appliances and architectural elements. 5. Bead Blasted Finish: This coating creates a uniform, textured surface by bombarding the stainless steel with small glass beads. It provides a unique visual effect and can hide surface imperfections. 6. Patterned Finish: Patterned coatings involve embossing or etching designs onto the stainless steel surface. They can create a wide range of patterns and textures, adding aesthetic appeal to various applications. 7. Colored Coatings: Stainless steel sheets can be coated with various colors using processes such as powder coating or electroplating. This allows for customization and adds a decorative element to the material. It is important to consider the specific requirements of your application when selecting a stainless steel sheet surface coating. Factors such as corrosion resistance, durability, aesthetics, and functionality should all be taken into account to ensure the best choice for your needs.

- Q: Can stainless steel sheets be bent or formed without cracking?

- Stainless steel sheets possess the ability to be bent or formed without any occurrence of cracking. The remarkable formability and ductility of stainless steel enables effortless bending, shaping, or forming into diverse configurations. Nevertheless, the degree to which stainless steel can be bent sans cracking hinges on various factors, such as the stainless steel's grade and thickness, the type of bending or forming technique employed, as well as the equipment and methodologies utilized. To avoid cracking, it is crucial to utilize appropriate bending tools, employ gradual and consistent pressure, and refrain from exerting excessive force or sharp bends. Additionally, enhancing the formability of stainless steel sheets and minimizing the risk of cracking during bending or forming procedures can be achieved by preheating or annealing them.

- Q: How are stainless steel sheets made?

- Stainless steel sheets are made through a process known as hot rolling. The production starts with melting various quantities of iron, nickel, chromium, and other elements in an electric arc furnace. This mixture is then cast into large rectangular blocks known as slabs. The slabs are heated to extremely high temperatures and then passed through a series of hot rolling mills. These mills consist of a set of large rollers that gradually reduce the thickness of the slab while increasing its length and width. As the slab passes through each rolling mill, it is continually squeezed between the rollers, resulting in a thinner and longer sheet. After the hot rolling process, the stainless steel sheet is annealed. Annealing involves heating the sheet to a specific temperature and then allowing it to cool slowly. This process helps to relieve internal stresses and improve the material's mechanical properties. The next step is pickling, where the sheet is immersed in an acid solution to remove any surface impurities and oxides. This enhances the appearance and corrosion resistance of the stainless steel. Once the pickling process is complete, the sheet is cold rolled. Cold rolling further reduces the thickness of the sheet and improves its surface finish. Cold rolling is performed at room temperature, which increases the hardness and strength of the stainless steel. Finally, the stainless steel sheet undergoes various finishing processes. These can include cutting to size, leveling, surface polishing, and coating to enhance its appearance or protect it from corrosion. Overall, the manufacturing process of stainless steel sheets involves a combination of melting, casting, hot rolling, annealing, pickling, cold rolling, and finishing processes. This ensures that the final product meets the desired specifications, including thickness, strength, and surface finish.

- Q: What is the difference between cold rolled and hot rolled stainless steel sheets?

- The manufacturing process and resulting surface finish are the primary factors that differentiate cold rolled and hot rolled stainless steel sheets. Cold rolled stainless steel sheets are made by rolling the steel at room temperature. This involves passing the steel through a series of rollers to reduce its thickness and achieve the desired shape. Cold rolling results in a smoother and more refined surface finish, with fewer surface defects and a tighter tolerance on thickness. Additionally, the process enhances the strength and hardness of the stainless steel sheet. On the other hand, hot rolled stainless steel sheets are produced by heating the steel above its recrystallization temperature and then rolling it through a series of rollers. This method is typically carried out at a higher temperature than cold rolling, resulting in a rougher surface finish. Hot rolling is commonly used for thicker sheets and leads to a more variable thickness and hardness compared to cold rolling. Regarding applications, cold rolled stainless steel sheets are commonly utilized in industries that require precise measurements, such as automotive, aerospace, and construction. The smoother surface finish makes them suitable for applications where aesthetics and surface quality are important. Conversely, hot rolled stainless steel sheets are often employed in applications that prioritize strength and durability, such as structural components in buildings, industrial machinery, and equipment. In conclusion, the main distinctions between cold rolled and hot rolled stainless steel sheets lie in the manufacturing process, resulting surface finish, and their respective applications. Cold rolled sheets offer a smoother surface finish and tighter thickness tolerance, while hot rolled sheets have a rougher surface finish and are more suitable for applications requiring strength and durability.

- Q: Are stainless steel sheets resistant to chemicals?

- Generally, chemicals do not pose a problem for stainless steel sheets. Stainless steel is famous for its ability to resist corrosion, which is why it is widely used in industries like chemical processing, pharmaceuticals, and food processing. The presence of elements like chromium and nickel in stainless steel forms a protective layer on its surface, preventing most chemicals from penetrating. However, it's important to note that the resistance to chemicals may vary depending on the grade and composition of the stainless steel used. In highly aggressive environments or when dealing with specific chemicals, it's advisable to consult a materials engineer or refer to compatibility charts to ensure the best stainless steel grade is chosen.

- Q: How do you prevent pitting corrosion on stainless steel sheets?

- To prevent pitting corrosion on stainless steel sheets, it is important to maintain a clean and dry surface, avoid exposure to corrosive environments or chemicals, and promptly clean off any contaminants or deposits. Additionally, applying a protective coating or passivation treatment can help enhance the corrosion resistance of the stainless steel sheets. Regular inspections and maintenance are also crucial to detect and address any signs of pitting corrosion early on.

- Q: Can stainless steel sheets be used for medical instrument trays?

- Indeed, medical instrument trays can make use of stainless steel sheets. The medical industry frequently utilizes stainless steel because of its remarkable resistance to corrosion, durability, and ease of cleaning. Medical instrument trays serve the purpose of storing and arranging diverse medical instruments during procedures. Stainless steel sheets are well-suited for this task due to their non-reactive nature and ability to withstand frequent sterilization processes, such as autoclaving. Furthermore, stainless steel possesses a sleek surface that can withstand scratches and dents, ensuring that the trays remain hygienic and easy to clean. All in all, stainless steel sheets prove to be a dependable and appropriate material option for medical instrument trays.

Send your message to us

Stainless Steel ASTM A240m 201/304/316L Stainless Steel Coil for Kitchen Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords