Stainless Steel Coils Strips Hot Cold Rolled Steel 316 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Commodity | Stainless Steel Coil |

Material | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430, etc. |

Surface | 2B, BA, 8K, No. 4 No.1 |

Standard | AISI, ASTM, DIN, EN, GB, JIS, etc. |

Specification | 1. Thickness : 0.3mm -120mm |

Application | 1. Automotive: Automotive trim and molding/Difficult-to-form exhaust-system components, tubular manifolds, mufflers/Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps ; |

Process | Hot rolled / cold rolled |

Productivity | 700 tons per month. |

Package | Standard seaworthy export packing or according to the customers' request. |

Delivery Time | It is based on the order, normally within 30 days after receiving your advance payment. |

Note | We can produce other standard as the customers' requirement. |

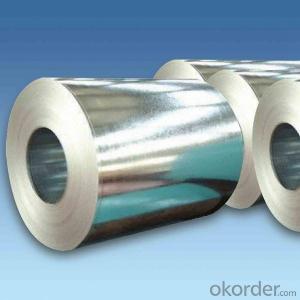

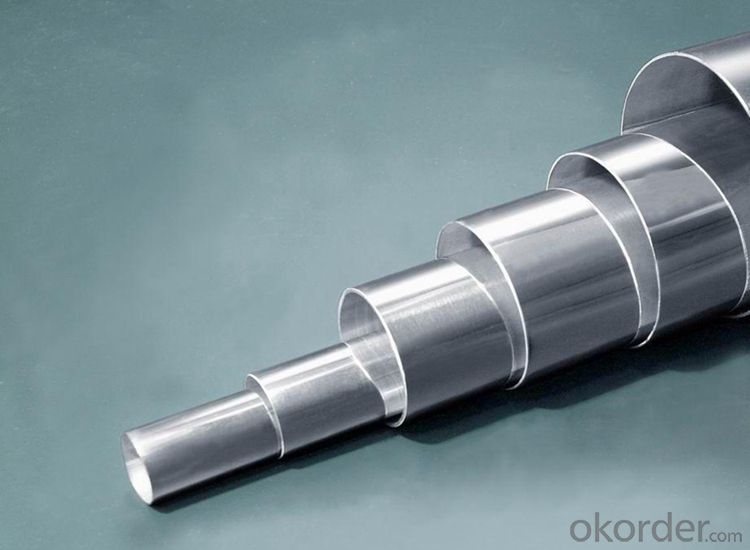

Detail picture for Stainless Steel Coils

Packaging & Delivery for Stainless Steel Coils:

Packaging Detail: Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

- Q: What are the limitations of using stainless steel sheets?

- There are a number of drawbacks associated with the use of stainless steel sheets. To begin with, stainless steel sheets can be quite costly in comparison to other materials. This can make them less viable for projects or applications with budget constraints. Furthermore, stainless steel sheets are relatively heavy, which can pose challenges in terms of handling and installation, especially when dealing with large quantities. This can lead to increased labor expenses and necessitate the use of additional equipment for transportation and installation purposes. Another issue is that stainless steel sheets are prone to scratching and denting. Despite being renowned for their durability, they are not completely resistant to physical damage. Scratches and dents can compromise both the appearance and functionality of the sheets, particularly in areas with heavy foot traffic or environments prone to potential impacts. Moreover, stainless steel sheets can be susceptible to corrosion, albeit to a lesser degree compared to other metals. Under certain conditions, such as exposure to saltwater or harsh chemicals, rust or other forms of corrosion may develop on stainless steel sheets. Regular maintenance and proper care are necessary to prevent or minimize this problem. Additionally, stainless steel sheets offer limited options when it comes to color. They generally come in shades of silver or gray, which may not be suitable for projects that require specific colors or specific aesthetic preferences. Lastly, stainless steel sheets exhibit poor insulation properties. They conduct heat and cold more effectively than other materials, resulting in greater energy loss and higher heating or cooling costs. In applications where insulation is vital, additional measures or alternative materials may need to be considered. To sum up, while stainless steel sheets possess numerous advantages such as strength, resistance to corrosion, and durability, they also have limitations in terms of cost, weight, vulnerability to damage, corrosion, limited color choices, and poor insulation properties. Understanding these limitations is essential when contemplating the use of stainless steel sheets in various applications.

- Q: What are stainless steel sheets used for?

- Stainless steel sheets are used for a variety of applications across various industries. Due to their excellent corrosion resistance, durability, and aesthetic appeal, these sheets are widely utilized in both commercial and residential settings. In the construction industry, stainless steel sheets are used for roofing, cladding, and facades, as they can withstand harsh environmental conditions and provide a modern, sleek appearance. In the automotive industry, they are commonly used for manufacturing car bodies, exhaust systems, and decorative trims. Moreover, stainless steel sheets find extensive use in the food and beverage industry, where their hygienic properties make them suitable for kitchen equipment, countertops, and food processing machinery. Additionally, these sheets are employed in medical equipment, pharmaceuticals, and laboratory settings due to their resistance to corrosion and easy cleanability. Other applications include furniture, appliances, signage, and decorative purposes, as stainless steel sheets can be easily customized and formed into various shapes and sizes. Overall, stainless steel sheets are a versatile material that meets a wide range of needs across different industries, thanks to their durability, strength, and corrosion resistance properties.

- Q: Are stainless steel sheets suitable for electrical enclosures?

- Yes, stainless steel sheets are suitable for electrical enclosures. Stainless steel is known for its excellent strength, corrosion resistance, and durability, making it an ideal material for protecting electrical components. It provides a high level of protection against environmental factors such as moisture, dust, and extreme temperatures. Additionally, stainless steel has good electrical conductivity, which is crucial for proper grounding and shielding. It also offers good electromagnetic compatibility (EMC), reducing the risk of electromagnetic interference (EMI) in sensitive electrical equipment. Moreover, stainless steel is easy to clean and maintain, ensuring a long-lasting and reliable enclosure for electrical applications.

- Q: Can stainless steel sheets be polished or brushed?

- Yes, stainless steel sheets can be both polished and brushed. Polishing stainless steel sheets involves using abrasive compounds to remove any imperfections or scratches from the surface, resulting in a smooth and reflective finish. On the other hand, brushing stainless steel sheets involves using abrasive pads or brushes to create a textured pattern or finish. This process creates a brushed appearance with fine parallel lines that can be either horizontal or vertical. Both polishing and brushing techniques can enhance the aesthetic appeal of stainless steel sheets and make them more resistant to corrosion.

- Q: What are the different types of stainless steel sheet patterns?

- Stainless steel sheet patterns come in a variety of options. Some of the most commonly used patterns are as follows: 1. The plain or smooth pattern: This pattern is the simplest and most basic, offering a smooth and flat surface. 2. The diamond pattern, also known as tread plate or checker plate: This pattern has raised diamond-shaped ridges, providing excellent slip resistance. 3. The tear drop pattern: Similar to the diamond pattern, this one has raised teardrop-shaped ridges, offering enhanced slip resistance. 4. The linen pattern: This pattern resembles the texture of linen fabric, with a series of parallel lines intersected by a crisscross pattern. 5. The quilted pattern: Resembling a quilted fabric, this pattern has a diamond-shaped or square-shaped design. 6. The hammered pattern: With a textured surface resembling the marks left by a hammer, this pattern adds visual interest and dimension. 7. The perforated pattern: Featuring small holes or perforations in the sheet, this pattern allows for improved ventilation and drainage in certain applications. These examples represent just a fraction of the stainless steel sheet patterns available. Each pattern offers unique aesthetic and functional advantages, providing greater versatility in design and application.

- Q: How do I prevent galling on stainless steel sheets?

- To prevent galling on stainless steel sheets, there are several steps you can take: 1. Lubrication: Apply a suitable lubricant to the stainless steel sheets, especially in areas where they come into contact with other surfaces or materials. Lubrication reduces friction and helps prevent galling. 2. Avoid using similar metals: When stainless steel sheets come into contact with other stainless steel surfaces, galling can occur due to the transfer of metal particles. To prevent this, try to use dissimilar metals or non-metallic materials that are compatible with stainless steel. 3. Surface finish: Ensure that the stainless steel sheets have a smooth surface finish. Rough surfaces can increase friction and the likelihood of galling. Consider using polishing or grinding techniques to achieve a smoother surface. 4. Control contact pressure: Excessive pressure between stainless steel sheets can lead to galling. Try to minimize contact pressure by adjusting clamping forces or using gaskets, washers, or other materials that distribute the load evenly. 5. Slow down the sliding speed: High sliding speeds can contribute to galling. Slowing down the movement or using anti-galling coatings can reduce the risk of galling on stainless steel sheets. 6. Regular maintenance: Inspect the stainless steel sheets regularly for signs of wear or damage. Address any issues promptly to prevent further damage that could lead to galling. By following these preventive measures, you can significantly reduce the occurrence of galling on stainless steel sheets, ensuring their longevity and optimal performance.

- Q: Can stainless steel sheets be used for kitchen countertops?

- Yes, stainless steel sheets can be used for kitchen countertops. Stainless steel is a popular choice for kitchen countertops due to its durability, heat resistance, and hygienic properties. It is resistant to stains, corrosion, and rust, making it a suitable material for a high-traffic area like the kitchen. Stainless steel countertops are also easy to clean and maintain, making them a practical option for busy kitchens. Additionally, stainless steel adds a sleek and modern look to the kitchen, making it a popular choice for contemporary and industrial-style kitchens.

- Q: What are the different types of stainless steel sheet surface patterns?

- In various industries, different types of surface patterns are commonly used for stainless steel sheets. Here are some of the most prevalent patterns: 1. The most commonly used pattern for stainless steel sheets is the No. 1 Finish. This pattern is achieved by hot rolling the sheet, resulting in a dull, rough, and non-reflective finish. 2. The No. 2B Finish has a smooth and moderately reflective surface. It is obtained through cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere to eliminate any scale or oxide buildup. 3. Similar to the No. 2B finish, the No. 3 Finish has a slightly coarser and less reflective surface. It is often used for decorative purposes, particularly in architectural applications. 4. The No. 4 Finish is a popular choice for stainless steel sheet surfaces. It showcases a brushed appearance with fine parallel lines running in one direction. This brushed finish is achieved by using abrasive belts or brushes to create a consistent pattern on the surface. 5. The No. 8 Mirror Finish provides a highly reflective, mirror-like surface, as the name suggests. It is achieved by polishing the stainless steel sheet to a high shine using progressively finer abrasive materials. 6. The Embossed Finish displays a raised, textured pattern on the surface of the stainless steel sheet. It can be achieved through various methods, such as embossing rollers or heat transfer. 7. The Bead Blasted Finish offers a uniform, matte appearance with a slightly rough texture. It is created by bombarding the stainless steel sheet with fine glass beads at high pressure, resulting in a consistent and non-reflective surface. Each of these stainless steel sheet surface patterns possesses distinct aesthetic and functional qualities. The choice of pattern depends on the specific application and desired outcome, whether it is for architectural, industrial, or decorative purposes.

- Q: Are stainless steel sheets safe for medical applications?

- Yes, stainless steel sheets are safe for medical applications. They are widely used in the medical industry due to their excellent corrosion resistance, biocompatibility, and durability. Stainless steel is easy to clean, sterilize, and maintain, making it suitable for surgical instruments, medical devices, and equipment used in healthcare settings.

- Q: Can stainless steel sheets be used in outdoor applications?

- Certainly, outdoor applications can indeed make use of stainless steel sheets. Stainless steel, known for its exceptional resistance against corrosion and oxidation, proves to be a perfect option for outdoor purposes. It can endure challenging weather conditions, encompassing rainfall, snowfall, and even UV radiation, without undergoing rust or deterioration. Moreover, stainless steel exhibits impressive durability, allowing it to withstand heavy burdens and impacts, rendering it appropriate for a multitude of outdoor applications such as cladding, roofing, fencing, and decorative elements. Its attractiveness in terms of aesthetics and minimal upkeep needs further contribute to its popularity in outdoor usage.

Send your message to us

Stainless Steel Coils Strips Hot Cold Rolled Steel 316 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords