Stainless Steel Coil Cold Rolled 304 BA With Great Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coil Cold Rolled 304 With Good Quality

1.Structure of Stainless Steel Coil Cold Rolled 304 With Good Quality

Cold Rolled stainless steel Coil with good quality is one of the raw material of the cold

rolled stainless steel Coil, which can be used directly in many places. Stainless Steel

(Stainless Steel) is short for acid-proof Stainless Steel, resistant to weak corrosive

medium such as air, steam, water, or with a Stainless Steel grade.

2.Main Features of Prefabricated Steel Structure High Building Project

1) Weld-ability: The purpose of the different requirement for welding performance are

different.1 Kind of tableware generally do not require the performance of welding, even

including some pot class enterprise. But the vast majority of products all need raw

materials welding performance is good, like the 2 kinds of tableware, thermos flask, steel

pipes, water heaters, water dispensers, etc.

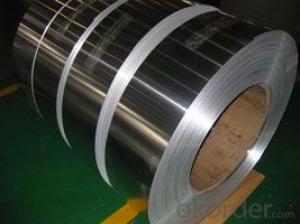

3. Stainless Steel Coil Cold Rolled 304 With Good Quality Images

4. Stainless Steel Coil Cold Rolled 304 With Good Quality Specification

The word "stainless steel" is not merely refers to a pure stainless steel, but said more than

one hundred kinds of stainless steel industry, the development of each stainless steel has

good performance in their specific applications. The key to the success of the first is to

make clear purpose, and then determine the correct material. Related to architectural

construction applications usually only six types of steel. They contain 17 ~ 22% chromium,

good steel contains nickel. Add molybdenum can further improve the atmospheric

corrosion resistance, especially containing chloride atmospheric corrosion resistance.

Stainless steel often according to the state of organization can be divided into: martensite

steel, ferritic steel, austenitic steel, austenitic (two-phase) - ferrite stainless steel and

precipitation hardening stainless steel, etc. In addition, according to ingredients can be

divided into: chromium stainless steel, chromium nickel stainless steel and chromium

manganese nitrogen stainless steel, etc.

Austenitic, ferritic duplex stainless steel The advantages of both austenitic and ferritic

stainless steel, and has the superplasticity. Austenite and ferrite The title Each accounts

for about half of the stainless steel. In the case of contain low C, Cr content was 18% ~

18%, Ni content at 3% ~ 3%. Some steel containing Mo, Cu, Si, Nb, Ti, N and other

alloying elements. This kind of steel both austenite and ferrite stainless steel, the

characteristics of compared with ferrite, plasticity and toughness is higher, no room

temperature brittleness, intergranular corrosion resistance and welding performance were

significantly increased, while maintaining a ferritic stainless steel of 475 ℃ brittleness and

high thermal conductivity, has the characteristics of superplasticity. Compared with

austenitic stainless steel, high strength and resistance to intergranular corrosion and

resistance to chloride stress corrosion is improved obviously. Duplex stainless steel has

excellent resistance to pitting corrosion performance, is also a kind of nickel and stainless

steel.

5. Applications of Stainless Steel Coil 304 With Good Quality

1. Kitchenware: tableware, cookware, Stoves…

2. Food packing: storage cans, food containers…

3. Construction: bridge, roofing, wall, decoration, bathroom accessories…

4. Precision instruments: electrical products, aerospace…

5. Others: automotive parts, machine building, chemical processing, farming…

6.FAQ of Stainless Steel Coil 304 With Good Quality

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,

is one of the large-scale professional investment casting production bases in China,

consisting of both casting foundry forging and machining factory. Annually more than 800

0 tons Precision casting and forging parts are exported to markets in Europe,America an

d Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we willprovide necessary

follow-up service assurance.

③How is the packaging and delivery?

Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden

box), or as your requirement and the delivery term is based on the project.

④How long can we receive the product after purchase?

In the purchase of product within 20 working days, We will arrange the factory delivery as

soon as possible. The specific time of receiving is related to the state and position of

customers. Commonly 20 to 40 working days can be served.

- Q:Are 111 stainless steel strips magnetic?

- Indeed, 111 stainless steel strips possess magnetism. Stainless steel, a collective term for alloys with at least 10.5% chromium content by mass, is known for its resistance to corrosion and tarnishing due to the addition of chromium. Nonetheless, specific grades like the 111 series retain magnetic characteristics. This is attributed to the inclusion of other elements like nickel and manganese in the alloy, enabling magnetism. As a result, 111 stainless steel strips can be attracted to magnets and display magnetic properties.

- Q:Are stainless steel strips resistant to chloride stress corrosion cracking?

- Yes, stainless steel strips are generally resistant to chloride stress corrosion cracking. Stainless steel is known for its excellent corrosion resistance properties, and this includes resistance to chloride stress corrosion cracking. This is due to the high levels of chromium present in stainless steel, which forms a protective oxide layer on the surface of the material, preventing the penetration of chloride ions and subsequent corrosion. However, it is important to note that the resistance to chloride stress corrosion cracking can vary depending on the specific type and grade of stainless steel used, as well as the specific environmental conditions in which the material is exposed. Therefore, it is always recommended to consult the manufacturer's specifications and guidelines to ensure the appropriate grade of stainless steel is selected for the intended application.

- Q:Can stainless steel strips be used in water distribution systems?

- Yes, stainless steel strips can be used in water distribution systems. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions and chemicals commonly found in water distribution systems. It is a durable and reliable material choice for ensuring the longevity and safety of water infrastructure.

- Q:How do you prevent discoloration of stainless steel strips?

- One way to prevent discoloration of stainless steel strips is to regularly clean them with a mild detergent and water, followed by thorough drying. Additionally, avoiding exposure to harsh chemicals, such as bleach or ammonia, and abrasive materials can help maintain the integrity and appearance of the stainless steel.

- Q:Are stainless steel strips heat resistant?

- Yes, stainless steel strips are heat resistant. They can withstand high temperatures without warping, becoming brittle, or losing their strength.

- Q:Are 111 stainless steel strips suitable for welding?

- Yes, 111 stainless steel strips are suitable for welding. Stainless steel 111 is a ferritic stainless steel grade that contains high amounts of chromium and low amounts of nickel. This composition makes it highly resistant to corrosion and oxidation, making it suitable for various welding applications. It is important to use the appropriate welding technique and filler material to ensure proper weldability and to achieve the desired strength and durability in the welded joints. It is always recommended to consult with welding experts or follow the manufacturer's guidelines for the specific type of stainless steel being used.

- Q:What is the elongation of stainless steel strips?

- The ability of stainless steel strips to stretch or deform under tension before breaking is referred to as elongation. It serves as a measure of the material's ductility or flexibility. Elongation is usually expressed as a percentage, indicating the increase in length when a tensile load is applied to the stainless steel strip. The specific elongation of these strips can vary depending on factors like alloy composition, manufacturing process, and grade of stainless steel. In general, stainless steel strips exhibit a high percentage of elongation, typically falling within the range of 40% to 60%. This exceptional elongation makes them suitable for applications in industries such as automotive, construction, and consumer goods, where flexibility and resistance against deformation are required.

- Q:What are the recommended guidelines for machining 111 stainless steel strips?

- When machining 111 stainless steel strips, it is recommended to follow certain guidelines to ensure optimal results. 1. Selection of cutting tools: Use cutting tools specifically designed for machining stainless steel. Carbide or high-speed steel tools are suitable options. Ensure the tools are sharp and in good condition. 2. Cutting speed: Maintain a moderate cutting speed to prevent excessive heat buildup. Generally, a cutting speed between 80 and 100 surface feet per minute (SFPM) is recommended for 111 stainless steel strips. 3. Feed rate: Use a feed rate that allows for efficient material removal without causing excessive tool wear. A feed rate of 0.005 to 0.015 inches per revolution (IPR) is typically suitable for 111 stainless steel strips. 4. Coolant and lubrication: Apply a suitable coolant or lubricant during the machining process. This helps reduce friction, heat, and tool wear. Water-soluble or oil-based coolant/lubricant can be used as per the machining conditions. 5. Tool geometry: Choose the appropriate tool geometry, such as a positive rake angle, to minimize cutting forces and improve chip evacuation. This helps prevent work hardening and tool breakage. 6. Workholding: Ensure secure and rigid workholding to minimize vibrations and improve surface finish. Use clamps or vice grips that provide sufficient grip without distorting the strips. 7. Chip control: Employ effective chip control measures, such as using chip breakers or chip evacuation systems, to prevent chip buildup and damage to the tool or workpiece. 8. Quality control: Regularly monitor the machining process to ensure dimensional accuracy, surface finish, and adherence to tolerances. Use appropriate measuring tools, such as calipers or micrometers, for quality control checks. 9. Safety precautions: Always follow safety guidelines and wear appropriate personal protective equipment (PPE) when machining stainless steel. This includes safety glasses, gloves, and hearing protection. It is important to note that these guidelines serve as general recommendations. The specific machining conditions, such as the width and thickness of the strips, the desired surface finish, and the machinery used, may require adjustments to these guidelines. Therefore, it is advisable to consult the manufacturer's recommendations and perform test cuts to optimize the machining process for 111 stainless steel strips.

- Q:Can stainless steel strips be used for wire mesh production?

- Indeed, wire mesh production can utilize stainless steel strips. Renowned for its robustness, longevity, and ability to withstand corrosion, stainless steel is a versatile substance. It can effortlessly be shaped into diverse forms, such as strips, which can subsequently be interwoven or fused to fabricate wire mesh. Given its exceptional mechanical attributes and immunity to rust and corrosion, stainless steel wire mesh finds extensive application in filtration, screening, and fencing. Consequently, stainless steel strips are an appropriate choice for manufacturing wire mesh.

- Q:Can 111 stainless steel strips be used in high-temperature applications?

- 111 stainless steel strips are not suitable for high-temperature applications. It is a type of stainless steel with low carbon content, commonly used for general purposes. Its maximum operating temperature is approximately 400-450 degrees Celsius (750-840 degrees Fahrenheit). To ensure adequate heat resistance and oxidation resistance at elevated temperatures, it is advisable to utilize stainless steel grades like 310, 316, or 321, which possess higher levels of chromium and nickel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil Cold Rolled 304 BA With Great Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords