Z150 Zinc Coating Steel Building Roof Walls Steel Coil ASTM 615-009

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for Community portal – Bulletin board, projects, resources and activities covering a wide range of Wikipedia areas.

Help desk – Ask questions about using Wikipedia.

Local embassy – For Wikipedia-related communication in languages other than English.

Reference desk – Serving as virtual librarians, Wikipedia volunteers tackle your questions on a wide range of subjects.

Site news – Announcements, updates, articles and press releases on Wikipedia and the Wikimedia Foundation.

Village pump – For discussions about Wikipedia itself, including areas for technical issues and policies.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

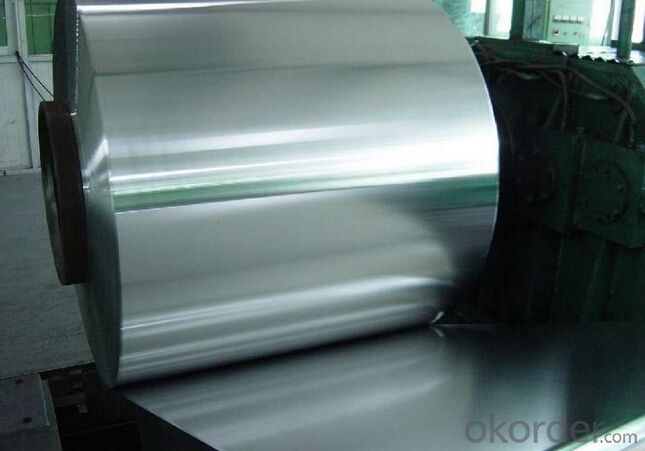

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:What are the alloying elements found in steel strips?

- The alloying elements found in steel strips vary depending on the specific grade and intended use of the steel. However, some common alloying elements found in steel strips include carbon, manganese, silicon, phosphorus, sulfur, chromium, nickel, and molybdenum. Carbon is the most important alloying element in steel as it provides strength and hardness. Manganese is often added to increase the hardenability and tensile strength of the steel strips. Silicon is used to enhance the steel's resistance to oxidation and improve its electrical properties. Phosphorus and sulfur are typically present in small quantities but can influence the steel's machinability and brittleness. Chromium is added to enhance the steel's corrosion resistance and increase its strength at high temperatures. Nickel is used to improve the toughness and ductility of the steel, especially in low-temperature applications. Molybdenum is commonly added to increase the steel's strength, hardness, and resistance to corrosion. Other alloying elements like vanadium, titanium, copper, and aluminum can be present, depending on the desired properties of the steel strips. Overall, the alloying elements found in steel strips are carefully selected to achieve specific mechanical, physical, and chemical properties, making the steel suitable for a wide range of applications in various industries.

- Q:How are steel strips plasma cut?

- To achieve a precise and clean cut on steel strips, a specialized cutting technique involving high-temperature plasma arc is utilized. The process commences by establishing an electrical circuit between the plasma cutter and the steel strip. This circuit facilitates the creation of a high-velocity jet of ionized gas, also referred to as plasma. When the plasma interacts with the steel strip, it swiftly heats up the metal, causing it to melt away. At the same time, a high-velocity stream of gas blows away the molten metal, resulting in a clean and accurate cut. To shape the steel strip precisely, the plasma cutter is guided along a predetermined path, either following a pre-programmed pattern or the operator's instructions. The speed and intensity of the plasma arc are adjustable and can be modified based on the thickness and composition of the steel strip. This ensures a highly efficient and accurate cutting process. Overall, plasma cutting is a versatile and extensively employed method for cutting steel strips due to its capability of producing precise and clean cuts, as well as its suitability for various thicknesses and grades of steel.

- Q:How are steel strips used in the power generation sector?

- Steel strips are commonly used in the power generation sector for various applications such as manufacturing of transformers, generators, and turbines. They are used to construct the core of transformers, which helps in efficient power transmission and distribution. Steel strips are also used in generators and turbines to provide structural support and enhance their durability. Additionally, steel strips are used in the construction of power plant infrastructure and equipment, ensuring reliable and robust operations in the power generation sector.

- Q:What are the forming processes used for steel strips?

- The forming processes used for steel strips include hot rolling, cold rolling, and continuous casting.

- Q:What is the surface finish of steel strips?

- The surface finish of steel strips can vary depending on their intended use and the manufacturing process employed. There are several common surface finishes for steel strips: 1. Hot-rolled: To achieve this finish, the steel strips are heated above their recrystallization temperature and then passed through a series of rollers. This results in a surface that is rough and scaled. 2. Cold-rolled: This finish is obtained by subjecting the hot-rolled steel strips to a series of cold reduction mills, which compress and shape the material. Compared to hot-rolling, cold-rolling produces a smoother and more refined surface. 3. Pickled and oiled: This finish involves immersing the steel strips in an acidic solution to remove any scale or impurities. Afterward, an oil coating is applied to protect against corrosion. The result is a clean, smooth, and slightly oily surface. 4. Galvanized: The steel strips undergo a process called galvanization, where a layer of zinc is applied. This finish provides excellent corrosion resistance and yields a shiny, metallic surface. 5. Electroplated: Through an electrochemical process, a thin layer of metal, such as chromium or nickel, is deposited onto the steel strips. Electroplating enhances durability and aesthetic appeal, and the resulting surface finish depends on the metal used. 6. Coated: Steel strips can be coated with various materials, such as paint, epoxy, or polymer, to enhance their appearance, corrosion resistance, or specific functional properties. The surface of coated steel strips can be smooth, textured, or patterned, depending on the coating material and application method. It's worth noting that the surface finish of steel strips can be further customized or modified to meet specific requirements. This includes achieving a desired roughness, reflectivity, or texture, whether for industrial purposes or decorative applications.

- Q:How do steel strips contribute to the strength of structures?

- Steel strips contribute to the strength of structures by providing structural support and reinforcement. They are often used in construction to increase the load-bearing capacity of beams, columns, and other structural elements. The high tensile strength and durability of steel make it an ideal material for withstanding heavy loads and resisting bending or warping. Additionally, steel strips can be strategically placed in specific areas of a structure to enhance its overall stability and prevent failure under stress or extreme conditions.

- Q:What are the environmental impacts of steel strip production?

- The environmental impacts of steel strip production are significant. The process involves high energy consumption, which contributes to carbon emissions and climate change. Additionally, the mining and extraction of iron ore, along with the production of coke and coal, result in habitat destruction and air pollution. Steel strip production also generates large amounts of waste, including slag and mill scale, which can contaminate soil and water bodies. Overall, it is crucial to implement sustainable practices and technologies to mitigate these environmental impacts.

- Q:How are steel strips used in the agricultural industry?

- Various applications in the agricultural industry make steel strips a widely used material. One of the primary uses of steel strips lies in the fabrication of agricultural machinery and equipment. Tractors, harvesters, plows, and other farm machinery rely on these strips to construct their frames, chassis, and structural components. In addition, steel strips find their place in the manufacturing of storage and handling systems for agricultural products. Silos, grain bins, and storage tanks are frequently built using these strips. These steel structures provide a durable and secure solution for storing grains, seeds, and other agricultural commodities. Steel strips are also employed in the construction of livestock enclosures and fencing. By forming them into panels or wires, strong and reliable fences can be created to contain livestock and safeguard crops from animals. Furthermore, irrigation systems in agriculture benefit from the utilization of steel strips. These strips are shaped into pipes and tubing, enabling the transportation of water from sources like wells, reservoirs, or rivers to the fields. The strength, durability, and corrosion resistance of steel strips make them the preferred choice for these irrigation applications. All in all, steel strips play a critical role in the agricultural industry, providing the necessary strength, durability, and versatility required for various applications. They contribute to the efficiency, productivity, and sustainability of agricultural operations, ultimately helping to meet the increasing global demand for food and agricultural products.

- Q:Can steel strips be used in high-temperature or heat-resistant applications?

- Indeed, steel strips prove to be highly useful in the realm of high-temperature or heat-resistant applications. Steel is renowned for its exceptional strength and durability, rendering it suitable for a wide range of industrial uses. When confronted with elevated temperatures, steel remains structurally intact, incapable of easily deforming or melting. Furthermore, specific variations of steel, including stainless steel or heat-resistant alloys, boast heightened resistance to extreme heat, having been purposefully designed for employment in such scorching environments. These particular steel strips often find common deployment in sectors such as automotive, aerospace, power generation, and manufacturing, where they encounter high temperatures, thermal cycling, or corrosive atmospheres. The heat-resistant qualities inherent in these steel strips imbue them with reliability and efficiency, rendering them optimal for employment in situations involving furnaces, boilers, heat exchangers, ovens, or exhaust systems.

- Q:What is the typical width-to-thickness ratio for steel strips?

- The typical width-to-thickness ratio for steel strips varies depending on the specific application and desired properties. However, in general, a common width-to-thickness ratio for steel strips is around 10:1.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Z150 Zinc Coating Steel Building Roof Walls Steel Coil ASTM 615-009

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords