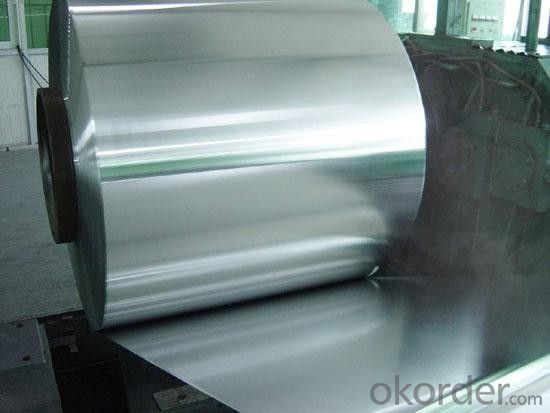

Stainless Steel Plate 420 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/316l/321,410/420/430/444/443/409L, and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: How to calculate the weight of stainless steel plate?

- The formula can be calculated according to the weight of stainless steel: area m2*, thickness mm*, density = kg / sheet to calculate the weight that the stainless steel can bear.Stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, corrosion of acid, alkaline gas, solution and other medium

- Q: How do stainless steel sheets differ from other types of metal sheets?

- Stainless steel sheets differ from other types of metal sheets in several ways. Firstly, stainless steel is an alloy that contains a minimum of 10.5% chromium. This chromium content forms a protective layer of chromium oxide on the surface of the metal, making it highly resistant to corrosion and staining. This unique property sets stainless steel sheets apart from other metals, as they can withstand exposure to harsh environments, chemicals, and moisture without deteriorating. Secondly, stainless steel sheets offer excellent strength and durability. Due to their composition, stainless steel sheets are highly resistant to heat, impact, and wear. This makes them suitable for a wide range of applications, including automotive, construction, and industrial settings, where strength and endurance are crucial. Another important distinction is the aesthetic appeal of stainless steel sheets. They have a sleek and modern appearance, which is highly sought after in architectural and interior design projects. Stainless steel sheets can be easily polished to a mirror-like finish, adding an elegant touch to any space. Moreover, stainless steel sheets are known for their hygiene and cleanliness. They have a non-porous surface that does not absorb moisture, making them resistant to bacteria, mold, and other contaminants. This makes stainless steel sheets the material of choice for kitchen appliances, food processing equipment, and medical devices. Lastly, stainless steel sheets are highly customizable. They can be manufactured in various thicknesses, sizes, and finishes to meet specific requirements. Additionally, stainless steel can be easily formed, welded, and fabricated, allowing for creative designs and customization options. In summary, stainless steel sheets differ from other types of metal sheets due to their exceptional corrosion resistance, strength, durability, aesthetic appeal, hygiene, and customization options. These unique characteristics make stainless steel sheets a versatile and reliable choice for a wide range of applications.

- Q: How do you determine the thickness of a stainless steel sheet?

- To determine the thickness of a stainless steel sheet, you can use a variety of methods such as using a micrometer, caliper, or measuring tape. These tools allow you to directly measure the thickness of the sheet by placing them perpendicular to its surface and reading the measurement displayed on the tool.

- Q: Can stainless steel sheets be used for pharmaceutical equipment?

- Indeed, pharmaceutical equipment can utilize stainless steel sheets. Stainless steel is highly favored in the pharmaceutical industry due to its remarkable resistance to corrosion, durability, and ease of cleaning. It does not react with other substances and does not emit any detrimental substances that could compromise the quality or purity of pharmaceutical products. Stainless steel sheets can be molded into different forms and sizes to cater to the specific needs of pharmaceutical equipment, including storage tanks, mixing vessels, sterilization devices, and piping systems. Additionally, the sleek surface of stainless steel hinders the buildup of bacteria, rendering it an exceptionally sanitary option for pharmaceutical applications.

- Q: What do stainless steel 304 industrial surfaces refer to?

- Stainless steel surface, there are many kinds, such as: BA, 2B, industrial.2B, is relatively smooth surface, industrial surface is more rough. These are raw materials, you can process the surface. But the industrial price is cheaper!

- Q: What is called anti fingerprint stainless steel sheet?

- The utility model improves the influence of fingerprints or oil pollution in the use of stainless steel products, and solves the difficult problem that the surface is easy to stick dirt and is difficult to clean. Meanwhile, the utility model avoids the defects of stainless steel surface damage, blackening or losing luster caused by the treatment of fingerprints or oil pollution by common chemical solvents. This is a new type of stainless steel surface processing technology, stainless steel material is not limited: such as 201#, 202#, 301#, 304#, 430#, 443# and so on can be processed!

- Q: What is the formability of stainless steel sheets?

- The formability of stainless steel sheets is generally good, as they can be easily shaped, bent, and formed into various complex shapes without cracking or breaking.

- Q: Can stainless steel sheets be painted?

- Painting stainless steel sheets is indeed possible. However, it is crucial to adequately prepare the surface beforehand to ensure the paint adheres well and maintains its quality over time. Thoroughly cleaning and degreasing the stainless steel surface is essential, along with removing any existing rust or oxidation. To facilitate adhesion, it is advisable to use a primer specifically designed for metal surfaces, followed by a high-quality paint suitable for metal. Additionally, applying a clear coat or sealer is recommended to protect the paint finish. It is important to note that regular upkeep may be necessary to preserve the appearance of the painted stainless steel sheets, as the paint may chip or wear with time.

- Q: What is the maximum width of stainless steel sheets available?

- The maximum width of stainless steel sheets can vary depending on the supplier and the specific requirements of the customer. However, in general, stainless steel sheets are commonly available in widths ranging from 36 inches (91.44 cm) to 72 inches (182.88 cm). Some specialty suppliers may offer wider sheets, reaching up to 96 inches (243.84 cm) or even wider. It is important to note that wider sheets may be subject to higher production costs and longer lead times. Customers should consult with their supplier to determine the maximum width available based on their specific needs.

- Q: 304 stainless steel plate 1*1219*C what do you mean?

- Roll thickness 1 mm, width 1219 mm, length is unlimited (depending on volume weight). 304 stainless steel is a kind of the most commonly used, law-abiding.

Send your message to us

Stainless Steel Plate 420 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords