Stainless Steel Metal Plate ASME 304 2B,NO.4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

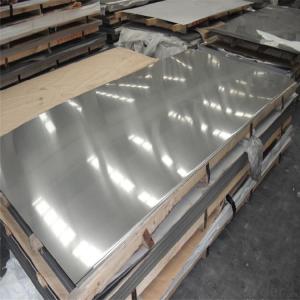

Stainless Steel Metal Plate ASME 304

Product Description

Model Name | Stainless Steel Metal Plate ASME 304 |

Type | 201,202,304,304l,316,316l,321,410,430 |

Color | Silver white |

Standard | ASTM, ASME, AISI, DIN |

Surface | No.1,No.4,2B,BA,HL,8K, mirror |

Thickness | 0.3-6.0mm, or as your requirement |

Width | 100mm-2000mm, or as your requirement |

Length | 1000mm-6000mm, or as your requirement |

Feature | Corrosion and heat resistance, good toughness |

Application | 1: Chemical industry equipment, industrial tanks 2: Medical instruments, tableware, kitchen utensil and kitchen ware. 3: Architectural purpose, milk or food processing facilities. 4: Hospital equipment, interior exterior decoration for building 5: Architectural purposes, escalators, kitchen ware and vehicles. Or they can be made as your requirement. |

Chemical Composition

Chemical composition of Stainless Steel 304 | ||||||||

chemical element | C | Si | Mn | P | S | Cr | Ni | Others |

Ingredient | <=0.07 | <=1.0 | <=2.0 | <=0.035 | <=0.03 | 17.0-19.0 | 8.0-11.0 | |

Physical Properties of Stainless Steel 304 | |

Tensile Strength (MPa) | 520 |

Compression Strength (MPa) | 205-210 |

Proof Stress 0.2% (MPa) | 205-210 |

Elongation A5 (%) | Min40 |

Hardness Rockwell B | 92 |

Packaging & Shipping

1.Packaging:All products are packaged according to the Standard export packing.In order to prevent friction damage and water erosion and so on.

2.Shipping: Ocean transportation,land transportation or air transportation.

- Q: Are stainless steel sheets suitable for food processing applications?

- Yes, stainless steel sheets are highly suitable for food processing applications. Stainless steel is known for its excellent corrosion resistance, making it ideal for use in environments that involve exposure to moisture, chemicals, and food substances. It is also non-porous, which means it does not absorb bacteria or other contaminants, making it hygienic and easy to clean. Stainless steel sheets are also heat resistant and can withstand high temperatures, making them suitable for cooking and processing applications. Additionally, stainless steel is durable and long-lasting, ensuring that it can withstand the demands of food processing operations. Overall, stainless steel sheets are a popular choice in the food industry due to their cleanliness, durability, and resistance to corrosion.

- Q: How do you clean and maintain stainless steel sheets?

- To clean and maintain stainless steel sheets, you can start by wiping them down with a soft cloth or sponge dipped in warm, soapy water. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. Rinse the sheets thoroughly and dry them with a clean cloth to prevent water spots. For regular maintenance, you can use a stainless steel cleaner or a mixture of equal parts water and vinegar to remove any fingerprints or smudges. Finally, remember to always wipe in the direction of the grain to maintain the steel's polished appearance.

- Q: What are the common types of corrosion that affect stainless steel sheets?

- Stainless steel sheets can be affected by various types of corrosion. Pitting corrosion is a common form that occurs when localized areas of the surface are damaged, causing small pits or holes. This corrosion is typically caused by exposure to chlorides, such as saltwater or certain chemicals. Another type is crevice corrosion, which happens in tight spaces or crevices where oxygen and other corrosive agents can become trapped. This can occur in joints between stainless steel sheets or in areas where dirt, debris, or moisture accumulate, creating a favorable environment for corrosion. Galvanic corrosion occurs when stainless steel comes into contact with a different metal in the presence of moisture. The electrical potential difference between the two metals results in the flow of electrical current, leading to corrosion of the stainless steel. Stress corrosion cracking is a type of corrosion that occurs under tensile stress in a corrosive environment. This can cause cracking or fracturing of stainless steel sheets, compromising their structural integrity. Lastly, intergranular corrosion occurs along the grain boundaries of stainless steel. It can result from improper welding practices, exposure to high temperatures, or chemical exposure. Intergranular corrosion weakens the stainless steel sheets and makes them more vulnerable to other forms of corrosion. To ensure the performance and durability of stainless steel sheets, it is important to consider these common types of corrosion. Regular inspections, proper maintenance, and appropriate corrosion prevention measures can help reduce the risk of corrosion and extend the lifespan of the sheets.

- Q: What's the difference between 304 stainless steel and 314?

- 304 stainless steel is a universal stainless steel material: 314 stainless steel; high temperature oxidation resistance and strong mechanical properties; high heat resistant stainless steel, and 314 austenitic stainless steel, high temperature oxidation resistance and creep resistance. 314 stainless steel used in furnace tube difference

- Q: What is the yield strength of stainless steel sheets?

- The yield strength of stainless steel sheets can vary based on the specific grade and thickness of the sheets. Typically, stainless steel sheets exhibit a yield strength between 30,000 and 100,000 psi. However, it is worth noting that different grades of stainless steel possess varying yield strengths. For instance, austenitic stainless steel grades such as 304 and 316 typically exhibit higher yield strengths in comparison to ferritic or martensitic stainless steel grades. Furthermore, the yield strength of stainless steel sheets can also be influenced by their thickness, with thicker sheets generally exhibiting higher yield strengths. Ultimately, it is crucial to refer to the specific grade and thickness of the stainless steel sheets in order to accurately determine their yield strength.

- Q: Stainless steel sheet welding method, thickness of 0.5mm

- Welding power university, rated matrix current, peak current, pulse frequency, pulse width and other parameters are not the same.

- Q: What are stainless steel sheets?

- Stainless steel sheets, which are composed of stainless steel, a type of alloy containing chromium, nickel, and other elements, are metal pieces that have a flat shape. These sheets possess exceptional resistance to corrosion, durability, and aesthetic appeal, which makes them highly versatile and extensively utilized in various industries. To achieve the desired thickness and finish, they undergo a manufacturing process known as hot rolling or cold rolling, where the steel is passed through a series of rollers. Stainless steel sheets find common applications in the construction, automotive manufacturing, kitchenware, appliances, and architecture sectors. They are available in different grades, surface finishes, and sizes to meet various requirements. Regardless of whether they are used for decorative purposes or functional applications, stainless steel sheets provide a dependable and enduring solution.

- Q: What is the typical thickness range for stainless steel sheets?

- The typical thickness range for stainless steel sheets is between 0.4mm and 6mm.

- Q: How do you drill holes in stainless steel sheets?

- To drill holes in stainless steel sheets, you will need to use a high-quality drill bit specifically designed for stainless steel. It is advisable to use a drill press or a stable drilling platform to ensure accuracy and prevent slippage. To reduce heat and friction, lubricate the drill bit with cutting fluid or a suitable lubricant. Begin by marking the desired hole locations on the sheet with a center punch, then start drilling at a slow speed, gradually increasing the speed as you progress. Be cautious not to apply excessive pressure to avoid damaging the sheet or causing the drill bit to break.

- Q: Is the cold rolled steel plate good or the stainless steel plate?

- The cold rolled steel itself, whether washed by acid car wash, semi-finished products, or rolled out by cold rolling mill semi-finished products, their rust resistance is very poor. It is easy to oxidize, resulting in rust on the surface of the air. It will not rust until it has been plated with aluminum or zinc, and it is clear that the process is complex and unsafe.

Send your message to us

Stainless Steel Metal Plate ASME 304 2B,NO.4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords