Hot-dip Aluzinc Steel Coil From Chinese Shandong

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

2.Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame,

4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

3.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

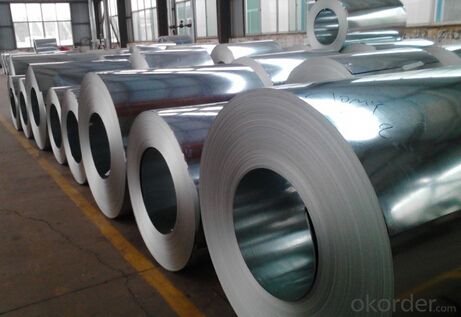

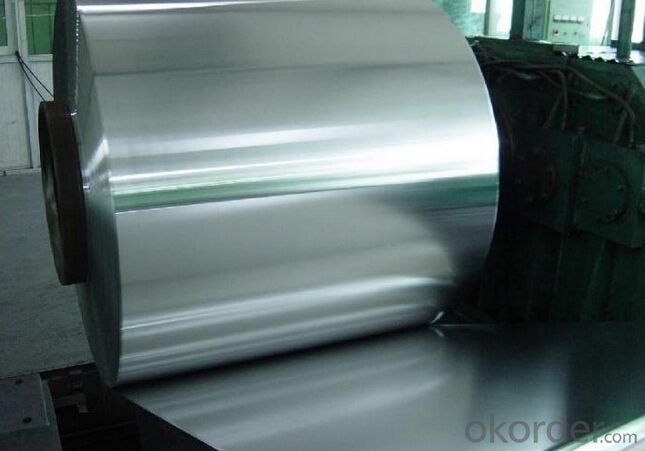

4.Hot-dip Aluzinc Steel Images

5.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION | HOT-DIP ALUZINC STEEL COILS |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | 30 g/ m2-185 g/ m2 |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S220GD+AZ S250GD+AZ S280GD+AZ S320GD+AZ S350GD+AZ S550GD+AZ | SGLC400 SGLC440 SGLC490 SGLC570 |

6.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1) What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2) What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

3) Could you let me approach about your company in Dubai?

Located at Jebel Ali Free Zone in Dubai, CNBM Dubai Logistics Complex is adjacent to -Jebel Ali sea port-the largest port in UAE and Al Maktoum Airport-the largest airport in the world, which covers an area of 50,000 square meters, including an fully enclosed warehouse by 10,000 square meters, an open yard by 25000 square meters, and 13 standard unloading platform. CNBM Dubai Logistics Complex formally put into operation on August 1, 2013. Dubai Logistics Complex will commit itself to build the most professional and most influential building materials distribution center of China’s building materials industry in the UAE and throughout the Middle East and Africa.

- Q: Can steel strips be used in the production of sporting equipment?

- Yes, steel strips can be used in the production of sporting equipment. Steel strips are commonly used for reinforcing and adding stability to various sporting equipment such as tennis rackets, golf clubs, and hockey sticks. They provide strength and durability to withstand the demands of athletic activities.

- Q: Can steel strips be used in the production of appliances?

- Yes, steel strips can be used in the production of appliances. Steel strips are commonly used in various appliances as they provide strength, durability, and resistance to corrosion. They can be used in the production of refrigerator shelves, oven racks, washing machine drums, dishwasher racks, and many other components of appliances.

- Q: Can steel strips be used for making electrical contacts?

- Steel strips are capable of being used to create electrical contacts. Steel, being a versatile material, possesses outstanding electrical conductivity and mechanical strength, rendering it appropriate for a multitude of applications, including electrical contacts. By manipulating steel strips, they can be transformed into an array of shapes, such as springs, clips, or connectors, thereby facilitating electrical connections between diverse components or devices. Additionally, applying coatings of metals such as nickel or silver onto steel strips serves to amplify their conductivity and safeguard against corrosion. In summary, steel strips present a dependable and economically viable alternative for fabricating electrical contacts in a wide range of industries, encompassing electronics, automotive, and telecommunications.

- Q: How are steel strips tested for internal defects?

- Steel strips are typically tested for internal defects using non-destructive testing methods such as ultrasonic testing or magnetic particle inspection. These techniques involve the use of specialized equipment to detect and analyze any internal flaws or irregularities in the steel strips without causing any damage to the material.

- Q: How are steel strips used in the production of metal grating?

- Steel strips are used in the production of metal grating to provide structural support and reinforcement, as they are strong and durable. These strips are typically welded or interlocked together to create a grid-like pattern, forming the base of the metal grating. This construction method ensures that the grating can withstand heavy loads and provide a stable walking surface, making it suitable for various industrial and commercial applications.

- Q: Are steel strips suitable for machining or drilling operations?

- Yes, steel strips are suitable for machining or drilling operations. Steel strips are commonly used in manufacturing processes and can be easily cut, shaped, or drilled to meet specific requirements. They have high strength and durability, making them ideal for various machining operations.

- Q: What are the different surface coatings available for steel strips to improve heat resistance?

- There are several surface coatings available for steel strips to enhance their heat resistance. Some common options include thermal spray coatings, such as ceramic or metal coatings, which provide a protective layer against high temperatures. Additionally, specialized heat-resistant paints and coatings, like silicone-based or epoxy-based coatings, can also be applied to steel strips to improve their heat resistance properties. These coatings create a barrier that prevents the steel from reaching high temperatures or undergoing thermal degradation.

- Q: How are steel strips measured for dimensional accuracy?

- To ensure dimensional accuracy, steel strips undergo measurement using a range of techniques and instruments. One commonly employed method involves the use of a digital caliper, a precision measuring tool featuring an adjustable jaw that fits the strip's width. With its digital readout, the caliper enables precise measurements. Another technique involves the utilization of a micrometer, a specialized measuring tool renowned for its high accuracy. A micrometer comprises a calibrated screw mechanism that is tightened around the strip, along with a scale or digital display for measurement readout. Apart from handheld instruments, automated measuring systems are available for measuring steel strips. These systems employ lasers or vision-based technology to swiftly and accurately assess the strip's dimensions. They find extensive application in industrial settings that require the measurement of large volumes of steel strips. Irrespective of the chosen method, it is crucial to ensure proper calibration of the measuring instrument. Additionally, measurements should be taken at multiple points along the strip to account for possible variations in width. This practice guarantees the maintenance of dimensional accuracy, which is vital for ensuring the steel strip's proper fit and performance across diverse applications.

- Q: What are the different surface buffing methods for steel strips?

- There are several different surface buffing methods for steel strips, including mechanical buffing, chemical buffing, and electrochemical buffing. Mechanical buffing involves using abrasive pads or wheels to remove surface imperfections and create a smooth finish. Chemical buffing uses chemical compounds to remove oxidation or stains from the steel surface. Electrochemical buffing utilizes an electrical current to remove surface contaminants and create a polished finish. Each method has its own advantages and is chosen based on the desired outcome and the specific requirements of the steel strip.

- Q: Are steel strips used in the production of household items?

- Yes, steel strips are commonly used in the production of various household items. They are utilized in the manufacturing of appliances, furniture, kitchenware, and other items due to their durability, strength, and versatility.

Send your message to us

Hot-dip Aluzinc Steel Coil From Chinese Shandong

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords