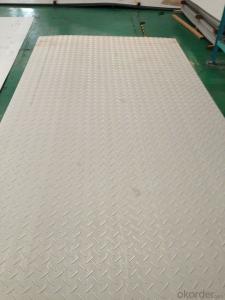

Stainless Steel 304 sheet with highest standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q:How do you prevent backflow in stainless steel pipes?

- To prevent backflow in stainless steel pipes, there are a few key measures that can be taken. 1. Install a backflow preventer: This is a mechanical device that is installed in the pipe system to ensure that water flows in one direction and prevents any backflow. There are different types of backflow preventers available, such as check valves, double check valves, and reduced pressure zone devices. The selection of the appropriate backflow preventer depends on the specific requirements of the system and local codes and regulations. 2. Regular maintenance and inspection: It is important to regularly inspect the backflow preventer and ensure it is functioning properly. Any signs of wear or damage should be addressed immediately to prevent potential backflow issues. Regular maintenance can also include cleaning and replacing any worn-out parts to ensure optimal performance. 3. Pressure regulation: Maintaining proper pressure in the stainless steel pipes can also help prevent backflow. High pressure can cause water to flow in the opposite direction, leading to backflow. By installing pressure regulators or pressure-reducing valves, the water pressure can be controlled and maintained within the recommended range. 4. Air gaps: Incorporating air gaps in the system can provide an additional layer of protection against backflow. An air gap is a physical separation between the water source and the point of use, ensuring that there is no direct connection that could allow backflow to occur. 5. Adequate system design: Proper system design is crucial in preventing backflow. By ensuring that the stainless steel pipes have the correct sizing, appropriate slope, and proper connections, the risk of backflow can be minimized. Additionally, locating the backflow preventer in an easily accessible area can facilitate regular maintenance and inspection. By implementing these preventive measures, the risk of backflow in stainless steel pipes can be significantly reduced, promoting the safe and efficient flow of water in the system.

- Q:What is the difference between seamless and welded stainless steel pipes?

- The main difference between seamless and welded stainless steel pipes lies in their manufacturing process and the resulting characteristics of the pipes. Seamless stainless steel pipes are produced by piercing a solid billet or ingot, heating it to a high temperature, and then rolling it into a hollow cylindrical shape. This process ensures that there are no seams or joints in the pipe, resulting in a smooth and uniform surface. Seamless pipes are generally considered to have higher strength and better corrosion resistance compared to welded pipes. They are also preferred in applications where high pressure or temperature is involved, as their seamless nature makes them more reliable and less prone to leaks. On the other hand, welded stainless steel pipes are manufactured by joining two or more pieces of steel together using various welding techniques. This process introduces a seam or weld line along the length of the pipe. Welded pipes can be produced in a continuous or intermittent welding process, depending on the required specifications. While welded pipes may have slightly lower strength and corrosion resistance compared to seamless pipes, advancements in welding technology have significantly improved their quality and performance. Welded pipes are generally more cost-effective and commonly used in applications where lower pressure or temperature is involved. In summary, the difference between seamless and welded stainless steel pipes lies in their manufacturing process and resulting characteristics. Seamless pipes, with no seams or joints, offer higher strength, better corrosion resistance, and are preferred in high-pressure or temperature applications. Welded pipes, with welded seams, are more cost-effective, commonly used in lower-pressure or temperature applications, and have seen significant improvements in quality and performance. Ultimately, the choice between seamless and welded pipes depends on the specific requirements of the application and cost considerations.

- Q:How do you calculate the weight of stainless steel pipes?

- In order to determine the weight of stainless steel pipes, several factors should be taken into account. Firstly, one needs to establish the pipe's outer diameter (OD) and thickness (T). Once these measurements have been obtained, the weight per foot (or meter) of the stainless steel pipe can be calculated using the following formula: Weight per foot (or meter) = (OD - T) * T * 0.0246615 It should be noted that this formula assumes the stainless steel pipe is of a circular shape. By multiplying the weight per foot by the length of the pipe in feet (or meters), the total weight can be determined. It is important to acknowledge that the density of stainless steel may vary depending on the specific grade and composition. Therefore, the weight calculated using this formula will provide an approximate value. For precise weight calculations, it is advisable to consult a reference table or contact the manufacturer for more accurate information.

- Q:What are the standard sizes for stainless steel pipes?

- Depending on the industry and application, the sizes of stainless steel pipes can vary. However, there are commonly used standard sizes that are widely accessible. Typically, stainless steel pipes are manufactured in nominal sizes ranging from 1/8 inch to 72 inches in diameter. These sizes are categorized using the Nominal Pipe Size (NPS) system, which refers to the approximate internal diameter of the pipe. Commonly used NPS sizes for stainless steel pipes range from NPS 1/8 to NPS 36. Additionally, stainless steel pipes are offered in different schedules, which indicate the wall thickness of the pipe. The most frequently used schedules for stainless steel pipes are Schedule 5, Schedule 10, Schedule 40, and Schedule 80. It is important to note that these standard sizes may slightly vary depending on the country or region. Therefore, it is recommended to consult the relevant standards and regulations specific to your location or seek guidance from a supplier to determine the exact standard sizes of stainless steel pipes available in your area.

- Q:What is the difference between seamless and hot-expanded stainless steel pipes?

- Seamless and hot-expanded stainless steel pipes are two different types of manufacturing processes for producing stainless steel pipes. Seamless stainless steel pipes are made by piercing a solid billet of stainless steel and then rolling it into a pipe shape. This process does not involve any welding or joining of separate pieces, resulting in a seamless pipe. Seamless pipes are known for their uniformity and strength, as there are no weak points or potential leak paths in the pipe. They are generally more expensive to produce and are used in applications where high corrosion resistance and pressure handling are required, such as in the oil and gas industry or in high-pressure boilers. On the other hand, hot-expanded stainless steel pipes are made by heating a stainless steel pipe and expanding it to a larger diameter using a mandrel inside the pipe. This process creates a larger diameter pipe with a uniform wall thickness. Hot expansion is typically used to produce larger diameter pipes that are required for specific applications. The hot expansion process can improve the mechanical properties of the pipe, such as increased tensile strength and improved resistance to corrosion. These pipes are commonly used in industries such as petrochemical, power generation, and construction. In summary, the main difference between seamless and hot-expanded stainless steel pipes lies in their manufacturing processes and the resulting properties of the pipes. Seamless pipes are made by rolling a solid billet, while hot-expanded pipes are created by heating and expanding an existing pipe. Seamless pipes are known for their strength and uniformity, while hot-expanded pipes are often used for larger diameter applications and can have improved mechanical properties.

- Q:How do you remove scratches from stainless steel pipes?

- To remove scratches from stainless steel pipes, you can try the following methods: 1. Cleaning: Start by cleaning the surface of the pipe with a mild dish soap and warm water. Use a sponge or soft cloth to gently scrub the scratched area and remove any dirt or debris that might be present. 2. Baking soda paste: Make a paste by mixing baking soda with water until it forms a thick consistency. Apply the paste to the scratched area and gently rub it in circular motions using a soft cloth. Rinse off the paste with warm water and dry the surface with a clean towel. 3. Toothpaste: Apply a small amount of non-gel toothpaste to the scratched area. Using a soft cloth or sponge, rub the toothpaste in gentle circular motions. Rinse off the toothpaste with warm water and dry the surface thoroughly. 4. Stainless steel cleaner: Look for a cleaner specifically designed for stainless steel surfaces. Follow the instructions provided on the cleaner's packaging, as different products might have varying application methods. Use a soft cloth or sponge to apply the cleaner and gently rub the scratched area. Rinse off the cleaner with warm water and dry the surface completely. 5. Stainless steel scratch remover kit: If the scratches are deep or extensive, you might want to consider using a stainless steel scratch remover kit. These kits typically include abrasive pads and a polishing compound that can help to buff out scratches. Follow the instructions provided with the kit to achieve the best results. Remember to always test any cleaning or scratch removal method on a small, inconspicuous area of the stainless steel pipe before applying it to the entire surface. Additionally, it's important to avoid using abrasive materials or harsh chemicals that could further damage the stainless steel.

- Q:Can stainless steel pipes be passivated?

- Yes, stainless steel pipes can be passivated. Passivation is a chemical process that is used to remove free iron and other contaminants from the surface of stainless steel pipes. This process is important as it helps to enhance the corrosion resistance of the stainless steel and improve its overall performance. Passivation is typically carried out by immersing the stainless steel pipes in an acid solution or applying a chemical solution to the surface. The solution helps to remove any impurities or contaminants from the surface, leaving a clean and corrosion-resistant layer. Passivation is commonly used in industries such as food and beverage, pharmaceuticals, and oil and gas, where stainless steel pipes are extensively used.

- Q:How do you clean and maintain stainless steel pipes?

- To clean and maintain stainless steel pipes, start by wiping them down with a mild detergent or soap and warm water using a soft cloth or sponge. Rinse thoroughly and dry with a clean cloth to prevent water spots. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. Regularly inspect the pipes for any signs of corrosion, staining, or damage, and promptly address any issues to prevent further deterioration. Additionally, applying a stainless steel cleaner or polish can help remove stubborn stains and restore the shine of the pipes.

- Q:Can stainless steel pipes be tempered?

- Yes, stainless steel pipes can be tempered. Tempering is a heat treatment process that is commonly used to improve the mechanical properties of steel. During tempering, stainless steel pipes are heated to a specific temperature and then cooled in a controlled manner. This process helps to reduce the hardness and brittleness of the steel, making it more ductile and less susceptible to cracking or breaking. Tempering can also help to enhance the corrosion resistance of stainless steel pipes. However, it is important to note that the exact tempering process and temperature will vary depending on the specific grade of stainless steel being used. Therefore, it is crucial to consult the manufacturer's guidelines or a metallurgical expert to determine the appropriate tempering process for stainless steel pipes.

- Q:How do stainless steel pipes compare to PEX pipes?

- Different plumbing systems require different characteristics and applications, making stainless steel pipes and PEX pipes suitable options. Stainless steel pipes are renowned for their durability and strength, making them ideal for water supply systems, especially in areas with aggressive water conditions. Their resistance to corrosion and ability to withstand high pressure and temperature make them suitable for both residential and commercial use. Moreover, stainless steel pipes are fire-resistant and have a long lifespan, requiring minimal maintenance and offering cost-effectiveness in the long term. On the other hand, PEX pipes, composed of cross-linked polyethylene, provide flexibility and easy installation. These pipes are highly resistant to freezing and bursting, making them a great choice for cold-climate regions. Their capacity to expand and contract reduces the risk of leaks or bursts caused by temperature changes. Additionally, PEX pipes are corrosion-resistant, eliminating the need for costly and time-consuming maintenance. They also dampen noise and vibration, providing a quieter alternative to metal pipes. When making a decision between stainless steel pipes and PEX pipes, it is crucial to consider specific plumbing requirements, budget, and local building codes. While stainless steel pipes excel in durability and strength, PEX pipes offer flexibility and ease of installation. Ultimately, the choice depends on the unique needs of the plumbing system and the preferences of the homeowner or plumbing professional.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel 304 sheet with highest standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords