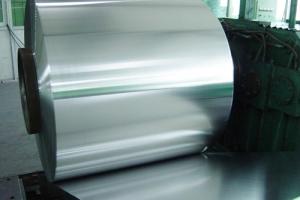

Embossed Decorative Stainless Steel Sheet for Household Eletrical Appliances

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Embossed Decorative Stainless Steel Sheet for Household Eletrical Appliances

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: Can stainless steel sheets be used for decorative wall panels?

- Yes, stainless steel sheets can be used for decorative wall panels. Their sleek and modern appearance, durability, and resistance to corrosion make them a popular choice for adding a decorative touch to walls in various settings such as homes, offices, restaurants, or commercial spaces.

- Q: What is the average lifespan of stainless steel sheets?

- The lifespan of stainless steel sheets can vary depending on factors such as the grade and quality of the stainless steel, the environment in which it is used, and the level of maintenance and care it receives. In general, stainless steel sheets are renowned for their durability and long-lasting nature. They are specifically engineered to withstand corrosion, rust, and other forms of degradation, making them suitable for a wide array of applications. Under ideal conditions and with adequate maintenance, stainless steel sheets can endure for several decades or even longer. However, in harsher environments that expose them to aggressive chemicals, extreme temperatures, or high levels of moisture, their lifespan may be shortened. To ensure the longevity of stainless steel sheets, it is crucial to engage in regular cleaning, proper storage, and routine inspections. By adhering to recommended maintenance practices, stainless steel sheets can deliver reliable performance and endure for an extended period.

- Q: Are stainless steel sheets good for pressure piping?

- Yes, stainless steel sheets are good for pressure piping. Stainless steel is a strong and durable material that can withstand high pressure levels without deforming or breaking. It has excellent corrosion resistance properties, which makes it suitable for use in piping systems that carry fluids or gases under pressure. Stainless steel sheets are also easy to clean and maintain, making them a reliable choice for pressure piping applications in various industries such as oil and gas, chemical, and food processing.

- Q: How do you remove fingerprints from brushed stainless steel sheets?

- To remove fingerprints from brushed stainless steel sheets, you can follow these simple steps: 1. Start by gathering the necessary cleaning supplies. You will need a microfiber cloth, mild dish soap, warm water, and a stainless steel cleaner or vinegar. 2. Begin by dampening the microfiber cloth with warm water. Make sure the cloth is not soaking wet, just slightly damp. 3. Gently wipe the stainless steel surface in the direction of the grain. It is important to always follow the grain to avoid causing scratches or streaks. 4. If the fingerprints persist, you can add a small amount of mild dish soap to the damp cloth and continue wiping the surface. Be sure to rinse the cloth thoroughly after applying the soap. 5. If the fingerprints are still visible, you can use a stainless steel cleaner specifically designed for brushed stainless steel surfaces. Apply a small amount of the cleaner onto the microfiber cloth and wipe the surface in the direction of the grain. Remember to follow the manufacturer's instructions for the specific cleaner you are using. 6. Alternatively, you can use white vinegar as a natural cleaning solution. Dampen a cloth with vinegar and gently wipe the surface in the direction of the grain. Vinegar can help remove fingerprints and restore shine. 7. Once you have removed the fingerprints, use a dry microfiber cloth to buff the surface gently. This will help remove any remaining streaks and give the stainless steel a polished finish. Remember to always test any cleaning solution on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. Additionally, avoid using abrasive materials or cleaners that contain chlorine or bleach, as they can damage the brushed finish of the stainless steel.

- Q: Can stainless steel sheets be used for swimming pool construction?

- Yes, stainless steel sheets can be used for swimming pool construction. Stainless steel is a durable and corrosion-resistant material, making it suitable for withstanding the harsh conditions of a swimming pool environment. It is commonly used for constructing pool walls, floors, and other structural components.

- Q: What is the electrical resistance of stainless steel sheets?

- The electrical resistance of stainless steel sheets can vary depending on several factors, such as the grade of stainless steel, its thickness, and the specific properties of the alloy used. Generally, stainless steel exhibits a relatively high electrical resistance when compared to other metals. This is primarily due to its composition, which includes a significant amount of chromium and other alloying elements that impede the flow of electric current. However, the precise value of electrical resistance can range from a few micro-ohms per square meter to several ohms per square meter, depending on the specific grade and thickness of the stainless steel sheet. Consequently, it is essential to refer to the manufacturer's specifications or conduct specific electrical resistance tests to obtain accurate values for a particular stainless steel sheet.

- Q: Can stainless steel sheets be used for elevator shafts?

- Yes, stainless steel sheets can be used for elevator shafts. Stainless steel is a durable and corrosion-resistant material that is commonly used in construction for its strength and aesthetic appeal. Elevator shafts require materials that can withstand constant use and exposure to various elements, making stainless steel an ideal choice.

- Q: Can stainless steel sheets be used for elevator wall panels?

- Yes, stainless steel sheets can be used for elevator wall panels. Stainless steel is a popular choice for elevator interiors due to its durability, cleanliness, and aesthetic appeal. It offers a sleek and modern look that can enhance the overall appearance of the elevator. Moreover, stainless steel is resistant to corrosion, stains, and scratches, making it suitable for high-traffic areas like elevators. It is also easy to clean and maintain, ensuring that the elevator walls remain in good condition for a long time. Additionally, stainless steel sheets can be customized in various finishes, patterns, and colors to match the design requirements and preferences of the building or elevator. Overall, stainless steel sheets are an excellent choice for elevator wall panels.

- Q: Are stainless steel sheets suitable for chemical reactors?

- Chemical reactors can utilize stainless steel sheets as they possess favorable properties for this purpose. The chemical industry often opts for stainless steel due to its exceptional resistance to corrosion. It can withstand a broad spectrum of chemicals, including acids, alkalis, and solvents, without experiencing significant deterioration or reacting with the substances being processed. The selection of stainless steel sheets for chemical reactors is primarily based on their high strength, durability, and ability to withstand high temperatures and pressure. They can endure the challenging conditions and aggressive substances encountered in chemical processes, all while maintaining their structural integrity. Furthermore, stainless steel sheets are easy to clean and maintain, making them well-suited for applications where cleanliness is of utmost importance, such as the pharmaceutical and food processing industries. They also exhibit excellent heat transfer properties, enabling efficient temperature control within the reactor. In conclusion, stainless steel sheets are a dependable option for chemical reactors due to their corrosion resistance, strength, durability, and thermal properties. They offer a secure and long-lasting solution for handling various chemicals, making them widely utilized in the chemical industry.

- Q: How do you prevent crevice corrosion on stainless steel sheets?

- To minimize the occurrence of crevice corrosion on stainless steel sheets, there are several steps that can be taken: 1. Maintaining cleanliness and performing regular maintenance: It is crucial to keep the stainless steel sheets clean and free from any contaminants. Regular cleaning using mild detergent and water, followed by thorough rinsing and drying, helps eliminate potential corrosive agents. 2. Avoiding the accumulation of debris or moisture: Ensuring that there are no crevices or gaps where debris or moisture can accumulate is essential. Regular inspection and maintenance can help identify and rectify any such areas. Additionally, maintaining effective drainage systems and preventing water pooling can help prevent moisture accumulation, which contributes to crevice corrosion. 3. Applying protective coatings: The application of protective coatings on the stainless steel sheets provides an additional barrier against crevice corrosion. Various types of coatings, such as paints, epoxy coatings, or specialized corrosion-resistant coatings designed for stainless steel, are available. 4. Using suitable gaskets and sealants: When fastening or joining stainless steel sheets, it is important to utilize compatible gaskets and sealants. These components should be corrosion-resistant and act as barriers against moisture and contaminants. Silicone-based sealants or gaskets made from PTFE (polytetrafluoroethylene) are commonly employed for this purpose. 5. Preventing galvanic corrosion: Galvanic corrosion can arise when dissimilar metals come into contact with each other in the presence of an electrolyte, leading to corrosion of the less noble metal. To prevent this, it is crucial to avoid using dissimilar metals in close proximity to stainless steel sheets. When necessary, insulating materials or coatings can be used to separate them. 6. Conducting regular inspections and maintenance: Regularly inspecting the stainless steel sheets for any indications of corrosion and promptly addressing them is crucial in preventing crevice corrosion. This includes checking for signs of pitting, discoloration, or degradation of the protective coatings. Any identified issues should be promptly resolved to prevent further corrosion. By adhering to these preventive measures, crevice corrosion on stainless steel sheets can be effectively minimized, thus ensuring their longevity and preserving their aesthetic appeal.

Send your message to us

Embossed Decorative Stainless Steel Sheet for Household Eletrical Appliances

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords