1/2 Aluminum Diamond Plate

1/2 Aluminum Diamond Plate Related Searches

1/2 Aluminum Plate Aluminum 1/2 Plate 1/4 Aluminum Diamond Plate 1/2 Inch Aluminum Plate 1/8 Aluminum Diamond Plate 1/4 Diamond Plate Aluminum 1/2 Thick Aluminum Plate 1/2 In Aluminum Plate 1 2 Aluminum Diamond Plate 1/4 Inch Aluminum Diamond Plate Aluminum Plate 1/2 Thick 1/8 Diamond Plate Aluminum 1/16 Diamond Plate Aluminum 1/2 Inch Thick Aluminum Plate 1/4 Inch Diamond Plate Aluminum 1/8 Black Aluminum Diamond Plate 1/8 Inch Aluminum Diamond Plate Aluminum Diamond Plate 1/4 Thick Half Inch Aluminum Plate Aluminum Plate 1/2 Inch Thick 1/8 Inch Diamond Plate Aluminum 1/4 Diamond Plate Aluminum Sheet 25 Aluminum Diamond Plate Weight Of 1/2 Aluminum Plate 1 4 Aluminum Diamond Plate 3/16 Aluminum Diamond Plate 1/2 Aluminum Plate Weight 1/4 Aluminum Plate 1/4 Plate Aluminum 1 16 Inch Aluminum Diamond Plate1/2 Aluminum Diamond Plate Supplier & Manufacturer from China

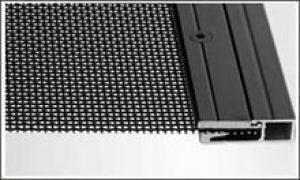

1/2 Aluminum Diamond Plate is a type of metal sheet material that features a distinctive diamond-shaped pattern on its surface, providing both an aesthetic appeal and enhanced traction. This product is known for its durability, corrosion resistance, and lightweight properties, making it a popular choice for various industrial applications.The 1/2 Aluminum Diamond Plate is widely used in a range of industries, including construction, transportation, and manufacturing. It is particularly useful in areas where slip resistance is crucial, such as walkways, ramps, and platforms. Additionally, its lightweight nature makes it an ideal choice for applications where weight is a concern, such as in the transportation industry for truck beds and trailer flooring. The product's corrosion resistance also makes it suitable for marine environments and outdoor applications where exposure to the elements is a factor.

Okorder.com is a leading wholesale supplier of 1/2 Aluminum Diamond Plate, offering a vast inventory of this product to cater to the needs of various industries. As a reliable source for this material, Okorder.com ensures that customers have access to high-quality 1/2 Aluminum Diamond Plate at competitive prices, making it an excellent choice for businesses looking to incorporate this versatile material into their projects.

Hot Products