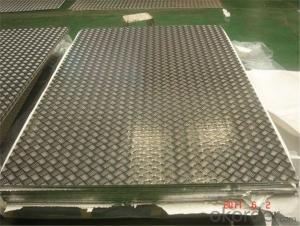

032 Aluminum Diamond Plate Sheets - Embossed Aluminum Sheet Five Bars Aluminum Sheet 0.1~5mm 3 Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

5 bar embossed aluminum sheet :

1.Thickness:0.8-12mm

2.Width:300-1900mm

3.factory price

4.ISO & SGS

0.1~5mm 3 bar embossed aluminum sheet five bars aluminum sheet

Product Description

Embossed aluminum sheet | |

Alloy grade | 1050,1060,1100,3003,3004,3105,5052,5005,5754,5083,6061,6063 etc |

Temper | 0,H12,H14,H16,H18,H22,H24,H26,H32,H34 |

Thickness | 0.8-12mm |

width | 10~1200mm |

length | 1000-10000mm |

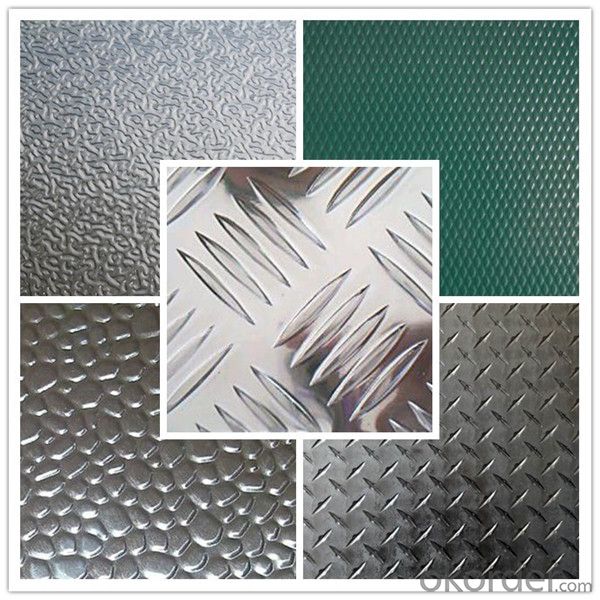

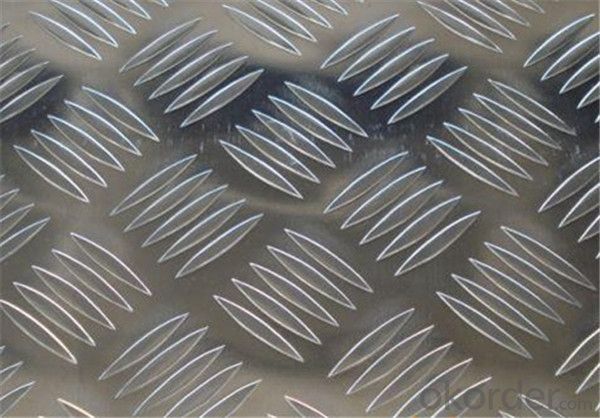

Decorative design | Five bars, classic stucco(orange peel), variation stucco, semi-circle, diamond ,three bars, two bars ,compass etc |

Coating | PE and PVDF |

Application/use | Widely used in refrigeratory house ,floor, freight car, ship, compartment lamp, construction platform ,air conditioner ,lift for skid-resistance etc |

Quality certificate | ISO 9001-2008 ,SGS |

Technical standard | GB/T 3880 |

MOQ | 3-5 tons, negotiable |

Payment terms | T/T or L/C |

Delivery | About 20~25 days after receipt of deposit |

Package | Export standard package |

Kindly remind | Our machine can cut any size according to your requirement |

FAQ

1, Question: What your mini order?

Answer: Our mini oder can be 5 tons. It just likes shopping. Good for you!

2, Question: If i buy larger quantity, is there any discount or good payment terms?

Answer: Take it easy,budy, we have the good financial policy like the credit period, it can enlarge your business.

3, Question: How can I get the best price?

Answer: For more than 20 years experience, we can keep the low the price in this aluminium market. Our products has been widely exported to U.A,.E, India, Unkraine, Europe and South American.We have the faith to keep the low price.

Photos

- Q: Are aluminum sheets affected by UV radiation or sunlight exposure?

- Yes, aluminum sheets are affected by UV radiation and sunlight exposure. Over time, exposure to UV radiation and sunlight can cause the aluminum sheets to oxidize, resulting in a dull and discolored appearance. Additionally, prolonged exposure to UV rays can weaken the material, making it more prone to cracking or breaking. To protect aluminum sheets from the damaging effects of UV radiation, it is recommended to apply a protective coating or use anodized aluminum, which has a more robust and durable surface.

- Q: Do aluminum cans melt in typical campfires? I know the melting point is about 660 Celsius but do campfires get that high? I thought it would just be that the can becomes disfigured and collapses due to the heat, not due to it melting. Even if it did melt in the fire how would you find the remains? The can in a liquid form would certainly not be confined to one part of the fire and therefore wouldn't solidify in a small pool to see if it had melted or not. Any ideas?

- Typical campfires do not get that hot. The can can become disfigured but it wont completely melt.

- Q: What specific considerations should be taken into account when using aluminum sheets in cold weather conditions?

- <p>In cold climates, aluminum sheets should be selected with consideration for their thermal expansion properties. It's important to use alloys with low thermal expansion coefficients to minimize distortion. Additionally, the design should account for potential contraction and expansion to prevent warping or cracking. Proper insulation and sealing are crucial to prevent condensation and moisture buildup, which can lead to corrosion. It's also advisable to use thicker sheets to enhance durability and resistance to the elements. Regular inspections and maintenance are recommended to ensure the longevity of aluminum structures in cold environments.</p>

- Q: Can aluminum sheet be used for electrical enclosures?

- Indeed, electrical enclosures can indeed utilize aluminum sheet. The remarkable conductivity, lightweight composition, and resistance to corrosion render aluminum a favored option for electrical enclosures. It effectively safeguards against electromagnetic interference and possesses commendable heat dissipation properties. Moreover, aluminum boasts malleability, enabling the production of intricate shapes and designs. In summary, aluminum sheet is a fitting material for electrical enclosures and finds widespread application in diverse industries like electronics, telecommunications, and power distribution.

- Q: Can 101 aluminum sheets be customized in terms of size and thickness?

- Yes, 101 aluminum sheets can be customized in terms of size and thickness according to specific requirements and needs.

- Q: A solid aluminum sphere has a mass of 83 g.Use the density of aluminum to find the radius of the sphere in inchesExpress your answer using two significant figures.I can't figure this out :(

- Aluminum's density is about 2.7 grams per cubic centimeter. So a sphere with a mass of 84grams has a volume of about 31.111 cubic centimeters. You get this by dividing 84 by 2.7. Now that you know the volume, you can calculate the radius of the sphere. for a sphere, volume = 4/3 pi * radius to the third power. So 31.111 = 4/3 * (3.14...) * r^3. Divide both sides by 4/3 then divide both sides by pi and you get something like r^3 is 7.427. Then find the cube root of this to find your radius. I don't have a calculator, so someone should check the numbers.

- Q: What are the different methods for engraving aluminum sheets?

- There are several different methods for engraving aluminum sheets, each with its own advantages and applications. 1. Laser engraving: This is one of the most popular methods for engraving aluminum sheets. It uses a laser beam to vaporize the aluminum surface, creating a permanent and precise engraving. Laser engraving offers high precision, speed, and versatility, making it suitable for a wide range of applications. 2. Mechanical engraving: This method involves using a mechanical tool, such as a rotary cutter or diamond-tipped tool, to physically remove material from the aluminum surface. Mechanical engraving can achieve deep and detailed engravings, making it suitable for applications where durability and depth are important. 3. Chemical etching: Chemical etching involves using chemicals to selectively remove material from the aluminum surface. It is a highly precise method that can create intricate and detailed designs. Chemical etching is often used in industries such as electronics and aerospace, where precision and high-quality finishes are required. 4. CNC milling: Computer Numerical Control (CNC) milling is a method that uses a computer-controlled machine to remove material from the aluminum sheet. It can achieve precise and complex engravings, making it suitable for applications that require intricate designs or 3D engravings. 5. Hand engraving: Hand engraving involves using handheld tools, such as gravers or chisels, to manually create engravings on the aluminum surface. While it may not offer the same level of precision as other methods, hand engraving allows for artistic freedom and customization. Each method has its own advantages and limitations, so the choice of engraving method depends on factors such as the desired design, level of detail, production volume, and budget.

- Q: What specific tools or equipment are required when working with aluminum sheets?

- <p>When working with aluminum sheets, you'll need a few special tools and equipment. These include sheet metal shears for cutting, a metal file for smoothing edges, a metal straight edge for measuring and marking, and a vise for holding the sheet securely. For bending, a sheet metal brake is essential. Safety gear such as gloves and goggles are also crucial to protect against sharp edges and debris. Additionally, a T-square and a marker are needed for precise measurements and markings.</p>

- Q: What's the difference between 6061 aluminum plate, 7075 aluminium plate and 6063 aluminum plate?

- Simply put, 6061 and 6063 belong to the 6 series, 6061 hardness in 90HB 6063 in 80HB, suitable for brazing, surface oxidation treatment is better, 7075 T6 hardness in 150HB, hardness is highestUsually 6061 and 6063 can be common

- Q: a dream I had where the carbon element was extracted from aluminum and ploished it became transparent, it was bendable and you could puncher it with out breaking it ?

- Aluminium is an element! Elements are pure substances, therefore aluminium doesn't contain any carbon. What do you mean?

Send your message to us

032 Aluminum Diamond Plate Sheets - Embossed Aluminum Sheet Five Bars Aluminum Sheet 0.1~5mm 3 Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords