8.79KG/M steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

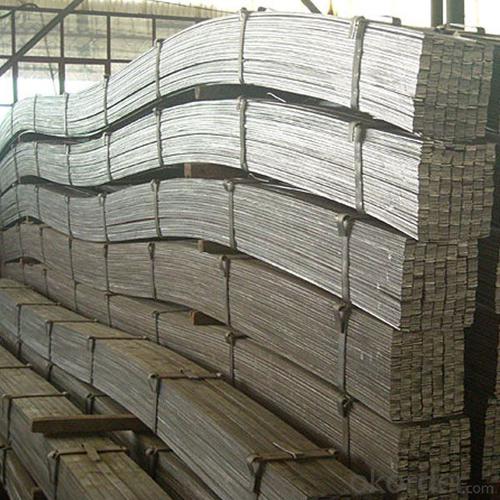

OKorder is offering 8.79KG/M steel flat bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

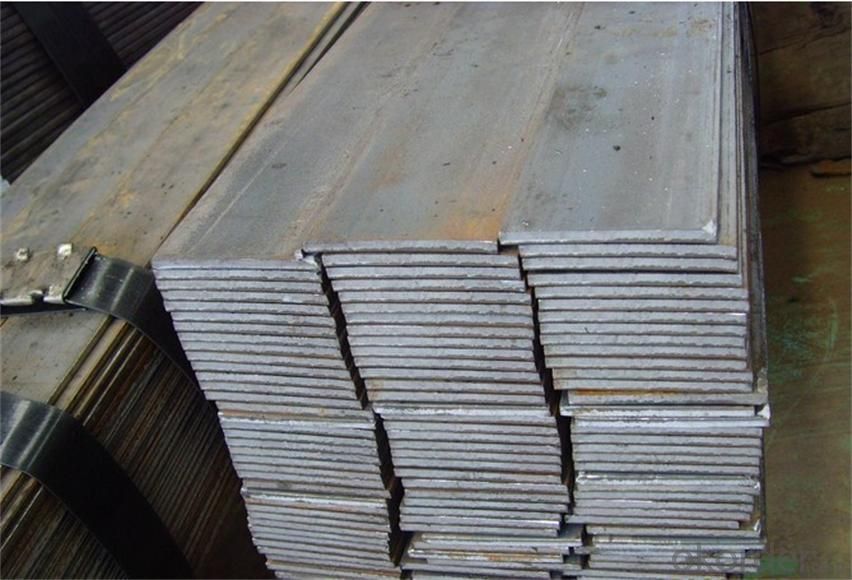

8.79KG/M steel flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar for construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: slited

Slitting precision (width) : 0.5 mm or less

Raw material: Q235B, Q345B, Q235-1 b

crosscutting precision (length) : 2 mm or less

Processing: the thickness of 2.0-16 mm;

Shear length: 2000 mm above

Wide degree: 15-1250 - mm;

Leveling precision: 1-2 MM square

Packaging: Export packing, nude packing, bundled

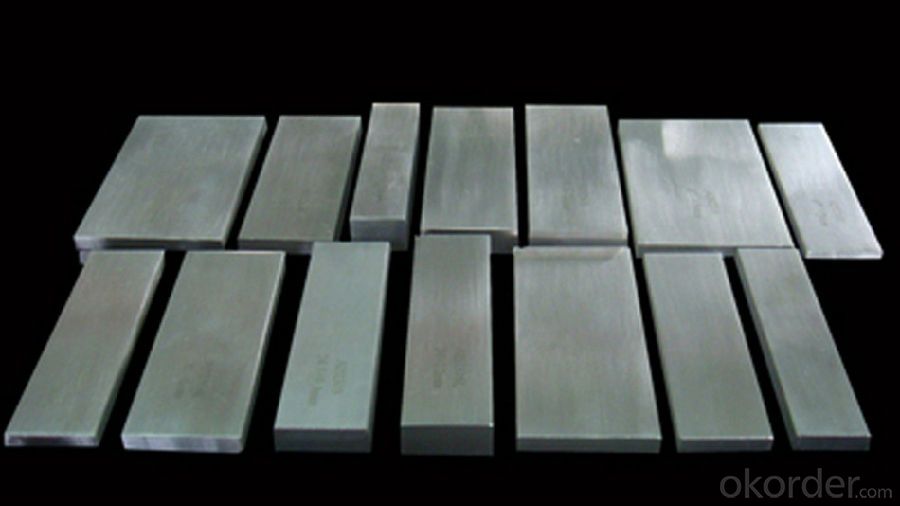

The Carbon Steel Flat Bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: What is the difference between 60X6 and 50X4 flat steel in grounding?

- The contact resistance varies with the return current.

- Q: Can steel flat bars be used in the manufacturing of material handling equipment?

- Yes, steel flat bars can definitely be used in the manufacturing of material handling equipment. Steel flat bars, which are commonly made from carbon steel, are known for their strength, durability, and versatility. These qualities make them ideal for various applications in material handling equipment, such as constructing frames, supports, brackets, and other structural components. Steel flat bars can be easily welded, cut, and formed into different shapes and sizes, allowing for customization and flexibility in the manufacturing process. Additionally, steel flat bars have excellent load-bearing capabilities, making them suitable for handling heavy loads and providing stability and reliability in material handling equipment. Overall, steel flat bars are a popular choice in the manufacturing of material handling equipment due to their strength, durability, and ability to meet the demanding requirements of such equipment.

- Q: Are steel flat bars suitable for machining operations?

- Yes, steel flat bars are suitable for machining operations. Steel flat bars are commonly used in various machining applications due to their versatility and durability. They can be easily machined using different processes such as cutting, drilling, milling, and turning. The flat surface of the bar provides a stable and consistent material for machining, allowing for precise and accurate operations. Additionally, steel flat bars offer excellent strength and toughness, making them ideal for heavy-duty machining tasks. Overall, steel flat bars are a reliable choice for machining operations in industries such as manufacturing, construction, and automotive.

- Q: The function of ground lead out galvanized flat steel

- 1, galvanized flat steel, refers to the width 12-300mm, thickness 4-60mm, cross section is rectangular and with pure edge of galvanized steel. Galvanized flat steel can be finished steel, also can be galvanized pipe blank and galvanized belt.2. Main uses: galvanized flat steel used as a useful material, can be used to make iron, tools and machinery parts, building for housing, structural parts, escalators.

- Q: Can steel flat bars be hot-dip galvanized?

- Certainly! Hot-dip galvanization is applicable to steel flat bars. In this process, steel is submerged in a molten zinc bath, resulting in the formation of a protective layer on the steel surface. This layer serves as a shield against rust and corrosion, thereby enhancing the durability and longevity of the steel. Galvanizing steel flat bars is a common practice to bolster their resistance against environmental factors and extend their lifespan. Hot-dip galvanization is a widely employed technique for safeguarding steel products, such as flat bars, from the detrimental impacts of moisture, chemicals, and other corrosive elements.

- Q: What is flat steel, please?

- The contract and other documents will be of stainless steel edge width, edge thick size fill in complete, and main process other matters: Hot + cold drawing + pickling, polishing, annealing, solid solution, stainless steel according to the different needs of structure composed of a variety of stress components, also can make connections between components. Widely used in a variety of architectural and engineering structures, such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reaction tower, container rack and warehouse shelves.

- Q: How do I determine the strength of a steel flat bar?

- To determine the strength of a steel flat bar, you need to consider its grade, which indicates the alloy composition and mechanical properties of the steel. The grade is usually marked on the bar or can be obtained from the manufacturer's specifications. Additionally, you can refer to industry standards or consult engineering handbooks that provide information on the strength and properties of various steel grades.

- Q: Are steel flat bars suitable for earthquake-prone areas?

- Yes, steel flat bars are suitable for earthquake-prone areas. Steel is a strong and durable material that can withstand seismic forces better than other materials. Flat bars provide structural stability and can be used in various applications such as reinforcing structures, bracing walls, or constructing seismic-resistant frames.

- Q: Can steel flat bars be used in the manufacturing of agricultural machinery?

- Yes, steel flat bars can be used in the manufacturing of agricultural machinery. Steel flat bars offer high strength and durability, making them suitable for various components and structures in agricultural machinery such as frames, brackets, and supports. They can withstand heavy loads, provide stability, and withstand harsh environmental conditions commonly encountered in agricultural operations. Additionally, steel flat bars can be easily fabricated, welded, and machined to meet specific design requirements, making them a versatile choice for manufacturing agricultural machinery.

- Q: How do steel flat bars compare to other materials like aluminum or wood?

- Steel flat bars possess several advantages over alternative materials such as aluminum or wood. To begin with, steel is renowned for its robustness and longevity. Steel flat bars are capable of enduring heavy loads and are less prone to warping or bending under pressure when compared to aluminum or wood. As a result, steel flat bars are frequently chosen for structural purposes or to provide support for hefty objects. Furthermore, steel flat bars exhibit exceptional resistance to corrosion. Unlike aluminum, which may corrode over time, steel is highly immune to rust and can maintain its integrity for a prolonged period. Consequently, steel flat bars are suitable for outdoor applications or in environments with elevated levels of moisture or humidity. Moreover, steel flat bars offer a remarkable level of versatility. They can be effortlessly welded, cut, or shaped to meet specific requirements. This adaptability in fabrication permits a broad range of design possibilities, establishing steel flat bars as a preferred option for various construction projects. Regarding cost, steel flat bars are generally more economical than aluminum. Although wood may initially be less expensive, steel provides a lengthier lifespan, reducing the necessity for frequent replacements and maintenance expenses. However, it is crucial to consider a few drawbacks. Steel is significantly heavier than aluminum, which can present challenges in transportation and installation. Additionally, steel possesses higher thermal conductivity, meaning it can conduct heat more readily than wood or aluminum. In applications where insulation is a priority, this can be a disadvantage. To conclude, steel flat bars offer superior strength, durability, and corrosion resistance in comparison to aluminum or wood. They exhibit remarkable versatility, cost-effectiveness, and suitability for a wide array of applications, rendering them a favored choice in various industries.

Send your message to us

8.79KG/M steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords