Flat Bar In I Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Spring Steel:

-Material: 70Si2CrA

-Production: Hot rolled or cold rolled

-Standard: GB/T·5218-1999

-Type: Spring Steel

-Alloy or no: Alloy

Chemical Composition:

C | Mn | Si | Cr |

0.65~0.75 | 0.40~0.60 | 1.40~1.70 | 0.20~0.40 |

S | P | Ni | |

≤0.030 | ≤0.030 | ≤0.030 |

Mechanical Properties:

-Annealing Condition:

1, Tensile Strength: σb/MPa:≤835

2, Elongation: δ/%:≥8

-Quencher condition:

1, Tensile strength: σb/MPa:785~1175

2, Elongation: -

Packaging & Delivery

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail:

1, Delivery time: 30~45 working days after receive buyer’s T.T. or L/C.

2, Delivery status should be written in the contract. (Heat treatment or no)

Usage/Applications

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

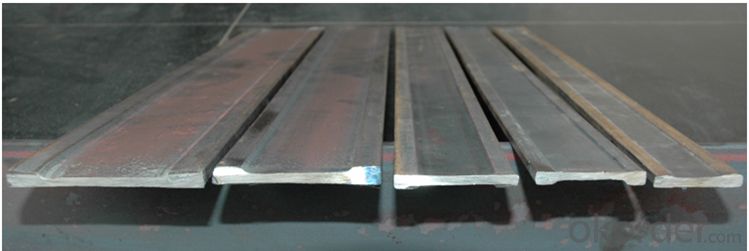

Production Flow of Steel Flat Bar

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

Packaging & Delivery of Steel Flat Bar

Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: What are the different methods of surface buffing for steel flat bars?

- There are several methods of surface buffing for steel flat bars, including hand buffing with abrasive compounds, mechanical buffing using a rotating wheel or belt, and electrochemical buffing that utilizes an electric current to remove surface imperfections.

- Q: What are the different types of surface treatments available for steel flat bars?

- There are several different types of surface treatments available for steel flat bars, each offering unique benefits and characteristics. Some of the most common types include: 1. Hot-dip galvanizing: This process involves immersing the steel flat bar in a bath of molten zinc, creating a protective layer that prevents corrosion and rust. Hot-dip galvanizing provides excellent durability and resistance to atmospheric conditions. 2. Powder coating: This technique involves applying a powdered polymer coating to the surface of the steel flat bar. The powder is electrostatically charged and then cured under heat, creating a tough and durable finish. Powder coating provides excellent resistance to impact, abrasion, and chemicals, while also offering a wide range of colors and finishes. 3. Electroplating: Electroplating involves depositing a thin layer of metal onto the steel flat bar through an electrochemical process. This can be done with various metals such as chromium, nickel, or zinc, depending on the desired properties. Electroplating enhances the appearance, corrosion resistance, and wear resistance of the steel. 4. Paint coating: Applying a paint coating to the steel flat bar is a common method of surface treatment. This can be done through various techniques such as spray painting or roller coating. Paint coatings not only provide a decorative finish but also offer protection against corrosion and environmental factors. 5. Anodizing: Anodizing is a process primarily used for aluminum, but it can also be applied to steel. It involves creating a controlled oxidization layer on the surface of the metal, which enhances corrosion resistance and provides an attractive finish. Anodizing can be done in various colors and provides excellent durability. 6. Phosphating: Phosphating involves treating the steel flat bar with a phosphate coating, usually through immersion in a solution containing phosphoric acid and other chemicals. This creates a thin, crystalline layer that enhances corrosion resistance and improves the adhesion of subsequent coatings or paints. These are just a few examples of the different surface treatments available for steel flat bars. The choice of treatment depends on factors such as the desired appearance, environmental conditions, and specific functional requirements of the steel flat bar.

- Q: What are the different grades of steel used for flat bars?

- There are several grades of steel used for flat bars, including low carbon steel (1018, A36), medium carbon steel (1045), high carbon steel (1095), alloy steel (4140), and stainless steel (304, 316). The choice of grade depends on the specific application and desired properties such as strength, durability, and corrosion resistance.

- Q: What is a steel flat bar?

- Made of steel, a steel flat bar is a metal bar that is long and rectangular in shape. It is commonly used in construction, manufacturing, and engineering. Due to its flat surface, it can be easily fabricated and installed in different projects. Steel flat bars have various applications such as structural supports, braces, frames, and reinforcement in concrete structures. They come in different sizes, thicknesses, and lengths to meet specific needs. Known for their strength, durability, and resistance to corrosion, steel flat bars are widely favored in numerous industries.

- Q: Can steel flat bars be used for making conveyor belts?

- Indeed, the utilization of steel flat bars is feasible when fabricating conveyor belts. These flat bars possess qualities of strength, durability, and resilience against wear and tear, rendering them appropriate for conveyor belt usage. They proficiently bear the weight of hefty loads, endure elevated temperatures, and withstand impact and abrasion. Furthermore, the seamless assembly of steel flat bars through simple welding or joining techniques enables the creation of an uninterrupted conveyor belt system. Ultimately, the sturdiness and dependability of steel flat bars contribute significantly to their widespread preference in the production of conveyor belts.

- Q: What are the different methods of surface hardening for steel flat bars?

- There are several methods of surface hardening for steel flat bars, including case hardening, nitriding, induction hardening, flame hardening, and laser hardening.

- Q: How do steel flat bars contribute to the overall safety of public structures?

- Public structures benefit greatly from the use of steel flat bars in various ways. Firstly, these bars possess immense strength and durability, making them an excellent choice for constructing essential components like beams, columns, and supports. This strength ensures that public structures can withstand external forces, such as heavy loads, wind, earthquakes, and other natural disasters, thereby minimizing the risk of collapse or damage. Additionally, steel flat bars exhibit remarkable resistance to fire. Unlike materials like wood or concrete, steel has a high melting point and does not combust or release toxic fumes when exposed to fire. This fire resistance capability adds an important layer of safety to public structures, enabling occupants to evacuate safely in the event of a fire emergency. Furthermore, steel flat bars display a high level of corrosion resistance, which is crucial for structures exposed to harsh weather conditions or environments with high moisture levels. Corrosion weakens materials over time and poses potential safety hazards. By utilizing steel flat bars, public structures can withstand corrosion and maintain their strength and safety for an extended period. Another advantage of steel flat bars lies in their versatility and ease of installation. Steel is a highly adaptable material that can be transformed into various shapes and sizes to meet specific design requirements. This versatility empowers engineers to create structures with intricate geometries and optimize load-bearing capacities, ensuring the overall stability and safety of public infrastructure. Lastly, steel flat bars possess excellent seismic resistance properties, making them ideal for regions prone to earthquakes. The flexibility and ductility of steel allow it to absorb and dissipate seismic energy, minimizing the impact of ground movements on the structure. This capability enhances the safety of public structures by reducing the risk of structural failure during seismic events. In conclusion, steel flat bars play a critical role in ensuring the overall safety of public structures. Their strength, fire resistance, corrosion resistance, versatility, and seismic resistance properties contribute to the durability, stability, and integrity of public infrastructure, providing a safe environment for the public to utilize and enjoy.

- Q: Are steel flat bars suitable for making brackets or supports for HVAC systems?

- Yes, steel flat bars are suitable for making brackets or supports for HVAC systems. Steel is known for its strength and durability, making it an ideal material for providing structural support. Additionally, steel flat bars can be easily shaped and welded, allowing for customization to fit specific HVAC system requirements.

- Q: Can steel flat bars be cold-formed or bent?

- Yes, steel flat bars can be cold-formed or bent. Cold-forming or bending is a process that involves shaping the metal at room temperature without the use of heat. Steel flat bars are commonly cold-formed or bent to create various shapes, angles, or curves to suit specific applications and designs. The process typically involves using specialized machinery such as press brakes or rollers to exert force on the steel flat bar, causing it to deform and take on the desired shape. Cold-forming or bending steel flat bars allows for precise customization and flexibility in design, making them suitable for a wide range of industries and applications such as construction, manufacturing, and engineering.

- Q: What is the difference between hot rolled and cold rolled steel flat bars?

- The main difference between hot rolled and cold rolled steel flat bars lies in the manufacturing process. Hot rolled steel flat bars are produced by heating a billet of steel above its recrystallization temperature and then rolling it into the desired shape. This process results in a rougher surface and slightly rounded edges. On the other hand, cold rolled steel flat bars are formed by passing the hot rolled bars through a series of rollers at room temperature, which gives them a smoother surface, tighter tolerances, and sharper edges. Additionally, cold rolled steel flat bars tend to have a higher strength and a more uniform thickness compared to hot rolled ones.

Send your message to us

Flat Bar In I Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords