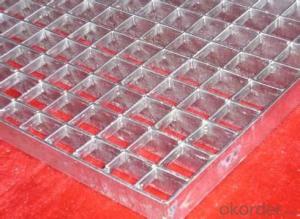

Steel Lattice Panel Grating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Superiority and application area

1. Material saving: It is the most material saving way under the same loading condition,can saving more backstand materials.

2. Investment reduction: Material saving, manual work saving, erection time saving, no need to clean and maintenance.

3. Easy erection working: Fix with bolt, on pre-set structure, one worker can finish.

4. Working time saving: No need rework on site, fast installation.

5. Durable in use: Hot zip galvanized and anti-rust treated before sell, durable in impact and pressure, have modern and fashion feeling.

6. Light structured: Less material, lighter structure, easier installation.

7. Dust and rubbish avoidable: Avoid cumulating of rain, snow, ice and dust.

8. Wind resistance reducing: Better in airiness, less wind resistance, reducing wind destroy.

9. Design simplified: No small support required, simple structure and design, no detailed grating design drawing required, only need to inform the ref number, the factory can design typeset for the customer.

10. Good at airiness, lighting, heat elimination, anti-riot, and anti-slip.

Usage/Applications of Steel Flat Bar

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

Production Flow of Steel Flat Bar

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

Packaging & Delivery of Steel Flat Bar

Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: What are the standards for the use of galvanized steel angles and flat steel for grounding?

- The distance of the grounding body from the building is over 1.5m, and the distance from the grounding rod of the independent lightning conductor is greater than 3m.(5) the connection of grounding wire and earthing body shall be done by lap welding.

- Q: How do steel flat bars perform under impact or shock-loading conditions?

- Steel flat bars generally perform well under impact or shock-loading conditions due to their high strength and resilience. The toughness and ductility of steel allow it to absorb and distribute the energy generated during impact, reducing the risk of deformation or fracture. Additionally, steel's ability to withstand high forces and maintain its structural integrity makes it a reliable choice for applications requiring resistance to impact or shock-loading.

- Q: Are steel flat bars available in different lengths and widths?

- Yes, steel flat bars are available in different lengths and widths.

- Q: What are the different storage and handling requirements for steel flat bars?

- Steel flat bars should be stored in a dry and well-ventilated area to prevent moisture buildup and minimize the risk of corrosion. They should be stored on a flat surface and stacked horizontally to prevent bending or deformation. Additionally, it is important to handle steel flat bars with care to avoid any damage to the surface or edges.

- Q: What are the different methods of surface coloring or tinting for steel flat bars?

- There are several methods available for surface coloring or tinting steel flat bars. These methods can enhance the appearance of the steel, provide protection against corrosion, or both. Some of the common methods include: 1. Paint: Painting is one of the most commonly used methods for coloring steel flat bars. It involves applying a layer of paint on the surface, which can be in any desired color. This method not only adds color but also provides a protective coating against rust and corrosion. 2. Powder coating: Powder coating is another popular method that involves applying a dry powder onto the steel surface. The powder is electrostatically charged and adheres to the steel, forming a durable and decorative coating. Powder coating provides a wide range of color options and offers excellent resistance to chipping, scratching, and fading. 3. Anodizing: Anodizing is a process commonly used to color aluminum, but it can also be applied to steel. In this method, a protective oxide layer is formed on the surface of the steel through an electrolytic process. This layer can be colored using dyes, resulting in a vibrant and long-lasting finish. 4. Galvanizing: Galvanizing is primarily used for corrosion protection, but it also imparts a silver-gray appearance to the steel flat bars. This method involves applying a layer of zinc onto the surface of the steel through a hot-dip or electroplating process. Galvanized steel offers excellent durability and resistance to rust. 5. Chemical coloring: Chemical coloring is a process that involves treating the steel with various chemical solutions to achieve different colors. This method can create unique and decorative finishes, such as black oxide, bronze, or even iridescent coatings. The colors obtained through chemical coloring are usually permanent and do not affect the structural integrity of the steel. 6. Patination: Patination is a natural process that occurs on steel surfaces over time, resulting in a unique color and texture. However, this process can be accelerated by treating the steel with chemicals or exposing it to specific environmental conditions. Patination can create various shades of brown, green, or blue, giving the steel flat bars a distinctive and aged appearance. It is important to note that the choice of coloring method may depend on factors such as the desired aesthetic, durability requirements, and the intended application of the steel flat bars.

- Q: Are steel flat bars suitable for food processing or hygiene-sensitive environments?

- No, steel flat bars are not typically suitable for food processing or hygiene-sensitive environments. While steel is generally a strong and durable material, it is not inherently resistant to corrosion or contamination. In food processing or hygiene-sensitive environments, the use of stainless steel is typically recommended. Stainless steel contains a higher percentage of chromium, which creates a protective layer on the surface of the metal, making it resistant to corrosion, staining, and bacterial growth. This makes stainless steel a more suitable choice for applications where cleanliness and hygiene are of utmost importance.

- Q: Can steel flat bars be used in outdoor applications?

- Steel flat bars are indeed viable for outdoor applications. Given steel's exceptional durability and resistance to weather, it is well-suited for a range of outdoor settings. Construction, landscaping, and outdoor furniture production often rely on steel flat bars due to their ability to endure moisture, sunlight, and extreme temperatures. Consequently, these bars prove ideal for outdoor use. Moreover, steel can be further fortified against corrosion through treatment or coating, ensuring even greater longevity when employed in outdoor scenarios.

- Q: Can steel flat bars be used for marine applications?

- Indeed, marine applications can make use of steel flat bars. Nevertheless, the choice of steel is of utmost importance in assessing its compatibility with marine surroundings. Specifically, stainless steel flat bars exhibit exceptional resistance to corrosion and, hence, are commonly employed in marine applications owing to their remarkable strength and durability. The capacity of stainless steel to resist rust and corrosion renders it suitable for deployment in saltwater environments, where conventional carbon steel would rapidly degrade. Consequently, when making a selection of steel flat bars for marine applications, it becomes crucial to opt for stainless steel in order to guarantee longevity and optimal performance in the face of challenging marine conditions.

- Q: Are steel flat bars cost-effective compared to other materials?

- Compared to numerous other materials, steel flat bars are widely acknowledged as being cost-effective. This is attributable to a range of factors. Firstly, steel is a material that is abundantly available, which helps to maintain its cost at a relatively low level. Moreover, steel possesses exceptional durability and a long lifespan, resulting in it being a cost-effective option in the long term since it necessitates minimal maintenance and replacement. Steel also boasts an outstanding strength-to-weight ratio, meaning that it can withstand substantial loads without being excessively heavy itself. Consequently, this may result in savings in terms of transportation and installation costs. Additionally, steel is highly versatile and can be conveniently fabricated into various shapes and sizes, including flat bars, rendering it suitable for a wide array of applications. On the whole, steel flat bars represent a cost-effective choice for numerous projects and industries.

- Q: What is the bending capacity of a steel flat bar?

- The bending capacity of a steel flat bar depends on various factors such as the dimensions of the bar, the type and grade of steel, and the specific application. To determine the bending capacity, engineers typically consider the yield strength, tensile strength, and modulus of elasticity of the steel. Additionally, the bar's width, thickness, and length will also affect its bending capacity. It is crucial to consult engineering reference materials or perform calculations to accurately determine the bending capacity of a specific steel flat bar.

Send your message to us

Steel Lattice Panel Grating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords