Din 1.7131 16mncr15 Alloy Structure Steel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

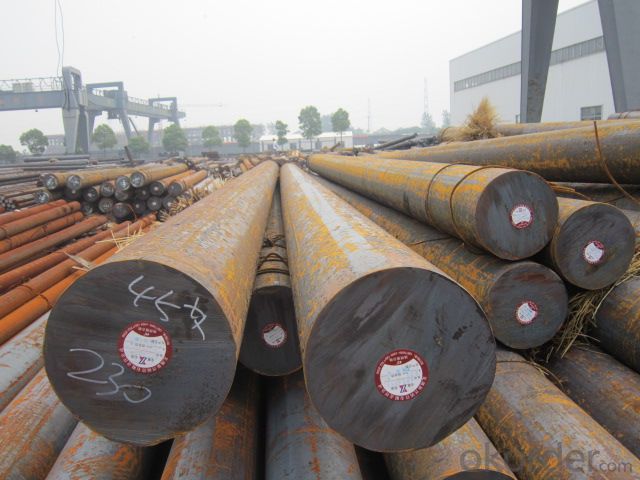

Din 1.7131 16mncr15 Alloy Structure Steel

Product information:

1.Standard: Chinese GB50221-2001, Or Equivalent.

2.Material: Grade Q235, or equivalent to ASTM A36.

Grade Q345, equivalent to ASTM A572.

3.Section: I / H section, or customlized profile.

4.Sand Blast: Sweden SA 2.5 Sand blasting.

5.Welding: Single level butt welding, fillet welding by electric arc welding, and Gas shielded welding.

6.Surface treatment: Zinc primer, Red primer, Hot-dip Galvanize and Powder painted.

7.Certification: ISO quality system.

8.Advantages:

a.Light weight with high strength.

b.Corrosion resistance.

c.Labor saving, time saving and cost saving.

d.Long time durable.

| What are details of din 1.7131 16mncr15 /alloy structure steel ? | ||||

| Name | Songshun din 1.7131 16mncr15 /alloy structure steel | |||

| Features | 1.Good hardenability and machinability. | |||

| 2.For Large cross-section parts,it can get high surface hardness and abrasive resistance. | ||||

| 3.High low temperature impact toughness. | ||||

| Applications | For making wheel gear; worm gear; plastic mould; the oil seal of steamship andgasoline set etc. | |||

| Sizes | Round bar | Diameter(mm) | Length(mm) | |

| 20~800 | 3000~5800 | |||

| Plate | Thickness(mm) | Width(mm) | Length(mm) | |

| Max:800 | 205~800 | 2000~4000 | ||

| The above is our regular size, We also can provide customized sizes! | ||||

| Packing | seaworthy packing; 20ft: GW:17.5T; (5.80mX2.13mX2.18m,) 40ft: GW:22T; (11.8mX2.13mX2.18m,) | |||

| Price | The price will change according to the weight of the steel you need. | |||

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

Special steel and there is no uniform definition of the concept of special steel is generally considered to have a special chemical composition (alloying), using a special production process, with a special organization and performance to meet the special needs of the steel type. Compared with ordinary steel, special steel has a higher strength and toughness, physical properties, chemical properties, biocompatibility and process performance.

China and Japan, the EU definition of special steel closer, into the special steel quality carbon steel, alloy steel, high alloy steel (alloying elements greater than 10%) three categories, including steel and high-alloy special steel production accounted for 70%. The main advantages of special steel carbon structural steel, carbon tool steel, carbon spring steel, alloy spring steel, alloy steel, ball bearing steel, alloy tool steel, high alloy tool steel, high speed tool steel, stainless steel, heat-resistant steel , and high-temperature alloys, precision alloy, electric alloy. There are nearly 2,000 special steel grades, about 50,000 varieties and specifications in the world currently. In addition to a wide range of special steel outside, in the specification with ordinary steel also showed different characteristics. In addition to plates, tubes, wire, strip, rods and profiles outside, as well as composite materials, surface alloying material, surface treatment material, forging materials, precision casting, powder metallurgy products.

- Q: What are the different methods of surface hardening for special steel?

- Special steel can be surface hardened using various methods. These methods comprise: 1. Carburizing: By subjecting the steel to a carbon-rich environment, such as gas or liquid, carbon atoms can infiltrate the steel surface. This results in enhanced surface hardness and wear resistance. 2. Nitriding: Steel is heated in an environment rich in nitrogen, causing nitrogen atoms to permeate the surface. This creates a durable, wear-resistant outer layer. 3. Induction hardening: By passing an alternating current through a coil, a magnetic field is generated, inducing electrical currents in the steel. The resistance to these currents generates heat, leading to high surface temperatures and rapid quenching, ultimately increasing hardness. 4. Flame hardening: The steel surface is heated using a flame or oxy-fuel torch, followed by quenching in water or oil. The swift cooling from elevated temperatures facilitates surface hardening. 5. Laser hardening: Laser beams are employed to rapidly heat a specific area of the steel surface, which is then promptly cooled with a coolant. This localized heating and cooling process enhances the hardness of the treated region. 6. Plasma nitriding: Steel is placed in a low-pressure plasma chamber, where nitrogen ions bombard the surface, facilitating nitrogen diffusion and the formation of a hardened layer. Each method offers distinct advantages and is suitable for diverse applications and types of special steel. The selection of a surface hardening method depends on factors such as desired hardness, dimensional limitations, and specific application requirements.

- Q: What are the different mechanical properties of special steel?

- Special steels exhibit a diverse array of mechanical characteristics that render them distinctive and well-suited for specific uses. Among the noteworthy mechanical properties of special steel are its exceptional strength, impressive toughness, commendable wear resistance, and superior corrosion resistance. Of all these properties, high strength emerges as a particularly crucial attribute of special steel. This inherent strength enables the material to withstand substantial loads and stress without succumbing to deformation or failure. As a result, special steel finds application in areas where the preservation of structural integrity and durability holds paramount importance, such as in the construction of buildings, bridges, and machinery. Another significant mechanical property of special steel lies in its toughness. This quality refers to the material's ability to absorb energy and withstand fracture when subjected to impact or sudden loads. Special steels possessing high toughness become indispensable in applications involving dynamic and high-impact forces, such as the fabrication of tools, gears, and machinery components. Wear resistance constitutes yet another critical mechanical property of special steel. It denotes the material's capacity to endure damage and deterioration caused by friction, abrasion, or erosion. Special steel boasting good wear resistance frequently finds employment in scenarios where it will be exposed to harsh conditions or repetitive mechanical actions, as witnessed in the manufacturing of cutting tools, dies, and molds. Of equal importance is the superior corrosion resistance offered by special steel. This mechanical property proves invaluable, particularly in environments where exposure to moisture, chemicals, or extreme temperatures looms likely. Special steels endowed with high corrosion resistance can withstand the adverse effects of oxidation, rust, and chemical reactions, rendering them eminently suitable for deployment in industries such as marine, chemical, and oil and gas. In conclusion, special steels possess a diverse range of mechanical properties that distinguish them from conventional steels. High strength, remarkable toughness, commendable wear resistance, and superior corrosion resistance represent a few of these key mechanical properties, rendering special steel the preferred choice for numerous industrial applications.

- Q: How is special steel used in the oil and gas industry?

- Special steel is used in the oil and gas industry for various applications such as manufacturing drill pipes, casings, and pipelines, as well as components for offshore platforms and equipment. It is highly resistant to corrosion, high temperatures, and extreme pressures, making it suitable for harsh environments and ensuring the integrity and safety of infrastructure in the industry.

- Q: What are the challenges in casting special steel?

- One of the challenges in casting special steel is the high melting point of the material. Special steels often have a higher carbon content or alloying elements, which increases their melting point. This requires the use of specialized furnaces and techniques to reach and maintain the necessary temperature for casting. Additionally, special steels can be prone to defects such as porosity, inclusions, and segregation during the casting process. These defects can negatively impact the mechanical properties and overall quality of the steel, making it difficult to achieve the desired specifications. Therefore, strict control over the casting conditions, including temperature, mold design, and pouring techniques, is crucial to overcome these challenges and produce high-quality special steel castings.

- Q: What are the applications of special steel in the electronics industry?

- Special steel is widely used in the electronics industry due to its unique properties and benefits. Some of the applications of special steel in this industry include the manufacturing of electronic components, such as connectors, springs, and contacts, which require high strength and corrosion resistance. Special steel is also used in the production of magnetic cores for transformers and inductors, as it exhibits excellent magnetic properties. Additionally, special steel is utilized in the fabrication of precision tools and equipment used in electronics manufacturing processes, ensuring high precision, durability, and reliability. Overall, the applications of special steel in the electronics industry contribute to enhanced performance, efficiency, and longevity of electronic devices and systems.

- Q: How long does special steel last compared to regular steel?

- Due to its unique composition and properties, special steel tends to have a longer lifespan than regular steel. Regular steel primarily consists of iron and carbon, while special steel is alloyed with elements like chromium, nickel, and molybdenum to enhance its strength, hardness, and resistance to corrosion. The lifespan of special steel is influenced by factors such as the specific type of steel, its usage conditions, and maintenance practices. However, in general, special steel has a significantly longer lifespan compared to regular steel. It exhibits greater resistance to wear and tear, corrosion, and high temperatures, making it suitable for demanding applications and environments. Industries such as aerospace, automotive, and construction extensively utilize special steel for critical components like engine parts, structural elements, and cutting tools. These components often endure high stress, friction, and exposure to harsh conditions. Special steel's exceptional properties enable it to withstand these challenges and maintain its performance for an extended period. Furthermore, special steel undergoes rigorous testing and quality control measures during its manufacturing process. This ensures that it meets specific industry standards and can endure extreme conditions without significant degradation. In contrast, regular steel may not possess the same level of durability or longevity. In conclusion, special steel generally lasts longer than regular steel due to its enhanced properties and resistance to wear, corrosion, and high temperatures. Although the exact lifespan may vary depending on various factors, special steel's superior characteristics contribute to its prolonged durability.

- Q: How is die steel used in metal stamping processes?

- Die steel is commonly used in metal stamping processes due to its high strength, hardness, and wear resistance properties. It is used to create dies, which are specialized tools that shape and cut metal sheets or strips into desired shapes. Die steel ensures that the dies can withstand the high forces and repetitive actions involved in metal stamping, allowing for precise and efficient production of various metal components and products.

- Q: What are the properties of low alloy steel?

- Low alloy steel is a type of steel that contains a small amount of alloying elements, typically less than 10%. These alloying elements can include elements such as manganese, chromium, nickel, and molybdenum. The properties of low alloy steel can vary depending on the specific alloying elements used, but generally, low alloy steel exhibits improved strength, hardness, and toughness compared to regular carbon steel. It also offers enhanced corrosion resistance and can withstand higher temperatures. Additionally, low alloy steel has good weldability and can be easily formed and machined.

- Q: What are the requirements for special steel used in high-strength applications?

- The requirements for special steel used in high-strength applications typically include high tensile strength, excellent toughness, good corrosion resistance, and the ability to withstand extreme temperatures. Additionally, the steel must possess good weldability and formability to facilitate the manufacturing process. Furthermore, it should meet specific industry standards and specifications to ensure its suitability for the intended application.

- Q: What are the main factors affecting the fatigue strength of special steel?

- The main factors affecting the fatigue strength of special steel include the material's microstructure, surface condition, heat treatment, and loading conditions. Additionally, factors such as environmental conditions, stress concentration, and the presence of defects or imperfections can also influence the fatigue strength of special steel.

Send your message to us

Din 1.7131 16mncr15 Alloy Structure Steel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords