All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

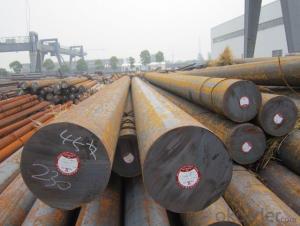

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the properties of electrical steel used in transformer cores?

Electrical steel used in transformer cores possesses several key properties. Firstly, it exhibits low core loss, which means it has minimal energy dissipation in the form of heat. This ensures efficient energy transfer within the transformer. Secondly, electrical steel has a high magnetic permeability, allowing it to efficiently conduct magnetic flux, resulting in effective transformation of electrical energy. Additionally, it has high saturation induction, enabling it to handle high magnetic field strengths without undergoing magnetic saturation. Lastly, electrical steel possesses excellent mechanical properties, such as high tensile strength and low hysteresis loss, ensuring the transformer core remains stable and durable over time.

How is steel used in the transportation sector, including railroads and public transit systems?

Steel is extensively used in the transportation sector, particularly in railroads and public transit systems, due to its strength, durability, and cost-effectiveness. In railroads, steel is used for the construction of tracks, bridges, and other infrastructure, providing a reliable and safe means of transportation. Similarly, in public transit systems, steel is used for the manufacturing of train and subway carriages, ensuring a sturdy and long-lasting mode of transportation for commuters. Overall, steel plays a vital role in the transportation sector by providing the necessary structural support and reliability for efficient and safe travel.

Can you elaborate on the methods used for non-destructive testing of special steel?

Non-destructive testing (NDT) methods used for special steel include techniques such as ultrasonic testing, magnetic particle testing, liquid penetrant testing, radiographic testing, and eddy current testing. Ultrasonic testing involves the use of high-frequency sound waves to detect internal flaws or defects in the steel. Magnetic particle testing uses magnetic fields and iron particles to identify surface cracks or flaws. Liquid penetrant testing involves applying a colored liquid to the surface of the steel and using a developer to highlight any defects. Radiographic testing uses X-rays or gamma rays to penetrate the material and create an image that can reveal internal flaws. Eddy current testing uses electromagnetic induction to detect surface or near-surface defects in conductive materials. These NDT methods play a crucial role in ensuring the quality and integrity of special steel without causing any damage to the material.

Wholesale Special Steel from supplier in Kyrgyzstan

We are a Special Steel supplier serving the Kyrgyzstan, mainly engaged in the sale, quotation, and technical support services of various Special Steel products in the Kyrgyzstan region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Special Steel procurement services in the Kyrgyzstan. Not only do we have a wide range of Special Steel products, but after years of market development in the Kyrgyzstan, we can also provide valuable experience for your projects.