All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

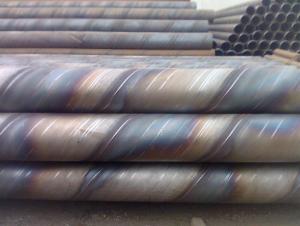

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel pipes integrated into the construction of underground tunnels for transportation?

Steel pipes are commonly used in the construction of underground tunnels for transportation as they serve various purposes. They are integrated into the tunnels to provide structural support, ensure the stability of the tunnel walls, and facilitate the transportation of utilities such as water, gas, and electrical cables. Additionally, steel pipes are used for drainage systems, allowing the efficient removal of water and preventing flooding within the tunnel.

What is the impact of water pH levels on the corrosion of steel pipes in plumbing and industrial systems?

The impact of water pH levels on the corrosion of steel pipes in plumbing and industrial systems is significant. pH levels below 7 (acidic) and above 8 (alkaline) can accelerate the corrosion process. Acidic water dissolves the protective oxide layer on the surface of steel, making it prone to rusting, while alkaline water can lead to the formation of scale deposits that promote localized corrosion. Therefore, maintaining an appropriate pH balance is crucial in preventing corrosion and ensuring the longevity and efficiency of steel pipes in plumbing and industrial systems.

What are the safety measures and regulations for transporting and handling steel pipes in various industries?

The safety measures and regulations for transporting and handling steel pipes in various industries include:

1. Proper securing and packaging: Steel pipes should be securely fastened and packaged to prevent movement and potential falling during transportation. This can be achieved through the use of strapping, wrapping, or palletizing.

2. Adequate lifting equipment: Steel pipes are often heavy and require specialized lifting equipment such as cranes, forklifts, or hoists. These should be used to ensure safe and controlled lifting and handling operations.

3. Personal protective equipment (PPE): Workers involved in transporting and handling steel pipes should wear appropriate PPE, including steel-toed boots, safety gloves, and protective eyewear to prevent injuries from sharp edges, falling objects, or flying debris.

4. Rigging and slinging techniques: Proper rigging and slinging techniques should be followed to secure the steel pipes during lifting and transportation. This includes using appropriate slings, hooks, and chains, ensuring even weight distribution and avoiding overloading.

5. Clear communication and signaling: Effective communication between workers involved in transporting and handling steel pipes is crucial to prevent accidents. Clear signaling and understanding of hand signals, radio communication, or other communication methods should be established.

6. Inspection and maintenance: Regular inspection and maintenance of transportation vehicles, lifting equipment, and packaging materials are essential to ensure their integrity and functionality. Any defects or damages should be promptly addressed to prevent accidents.

7. Compliance with regulations: Various industries have specific regulations and standards for the transportation and handling of steel pipes. These may include weight restrictions, load securement guidelines, and transportation permits. Compliance with these regulations is necessary to ensure safety and avoid legal consequences.

Overall, the safety measures and regulations for transporting and handling steel pipes aim to minimize the risk of accidents, injuries, and property damage, ensuring the well-being of workers and the integrity of the pipes during transportation and handling operations.

How do you join two steel pipes together?

To join two steel pipes together, a common method is to use welding techniques such as arc welding, MIG welding, or TIG welding. These processes involve melting the ends of the pipes and then fusing them together using a filler material to create a strong and durable joint. Other methods like threaded connections or flanges can also be used for joining steel pipes, depending on the specific requirements of the application.

Wholesale Steel Pipes from supplier in Mauritania

Whether you require seamless or welded steel pipes, we have a wide range of options to meet your specific needs. Our product offerings include carbon steel pipes, stainless steel pipes, alloy steel pipes, and more. We source our products from reputable manufacturers to ensure high-quality and reliable performance.

In addition to our comprehensive product range, we also provide value-added services such as cutting, threading, and coating to customize the steel pipes according to your project requirements. Our technical support team is well-trained and experienced, ready to assist you with any technical queries or challenges you may face.

As a subsidiary of CNBM, we have access to a global network of suppliers, ensuring a reliable and efficient supply chain for steel pipes. We understand the importance of timely delivery and strive to meet your project deadlines.

Whether you are involved in construction, oil and gas, water distribution, or any other industry that requires steel pipes, we are here to support you. Our team of sales professionals is dedicated to providing personalized service, offering competitive pricing, and finding the best solutions for your specific needs.

Contact us today to discuss your steel pipe requirements in Mauritania. Let us be your trusted partner in the distribution of steel pipes, providing you with convenient procurement services and valuable market insights.

In addition to our comprehensive product range, we also provide value-added services such as cutting, threading, and coating to customize the steel pipes according to your project requirements. Our technical support team is well-trained and experienced, ready to assist you with any technical queries or challenges you may face.

As a subsidiary of CNBM, we have access to a global network of suppliers, ensuring a reliable and efficient supply chain for steel pipes. We understand the importance of timely delivery and strive to meet your project deadlines.

Whether you are involved in construction, oil and gas, water distribution, or any other industry that requires steel pipes, we are here to support you. Our team of sales professionals is dedicated to providing personalized service, offering competitive pricing, and finding the best solutions for your specific needs.

Contact us today to discuss your steel pipe requirements in Mauritania. Let us be your trusted partner in the distribution of steel pipes, providing you with convenient procurement services and valuable market insights.