Grade SAE 4140 Steel Price Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade SAE 4140 Steel Price_Steel Round Bar

Details of Grade SAE 4140 Steel Price_Steel Round Bar

Name | Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

1.Size of 4140 Steel Round Bar | ||||||||

Round bar | Diameter(mm) | Length (mm) | ||||||

20~800 | 3000~9000 | |||||||

Plate | Thickness(mm) | Width (mm) | Length (mm) | |||||

Max:800 | Max:2200 | Max:9000 | ||||||

The specification can be customized. | ||||||||

2.Chemical Compositons | ||||||||

Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

42CrMo | 0.38~0.45 | 0.17~0.37 | 0.50~0.8 | ≤0.035 | ≤0.035 | 0.9~1.2 | 0.15-0.25 | ≤0.3 |

4140 | 0.40~0.45 | 0.15~0.35 | 0.75~1.0 | ≤0.035 | ≤0.040 | 0.8~1.1 | 0.15-0.25 | - |

SCM44 | 0.38~0.43 | 0.15~0.35 | 0.60~0.9 | ≤0.030 | ≤0.030 | 0.9~1.2 | 0.15-0.30 | ≤0.25 |

1.7225 | 0.38~0.45 | ≤0.40 | 0.60~0.9 | ≤0.025 | ≤0.035 | 0.9~1.2 | 0.15-0.30 |

|

3.Features of 4140 alloy steel | ||||||||

1. Chromium molybdenum alloy steel | ||||||||

2. Slightly higher carbon content then 4130 | ||||||||

3. Greater strength and heat treatment | ||||||||

4.Typical Applications | ||||||||

1. Applications in the oil and gas sector | ||||||||

2. Connection rods, collets, conveyor pins, | ||||||||

3. Gears, stem assemblies, | ||||||||

4. Pump shafts and tool holders | ||||||||

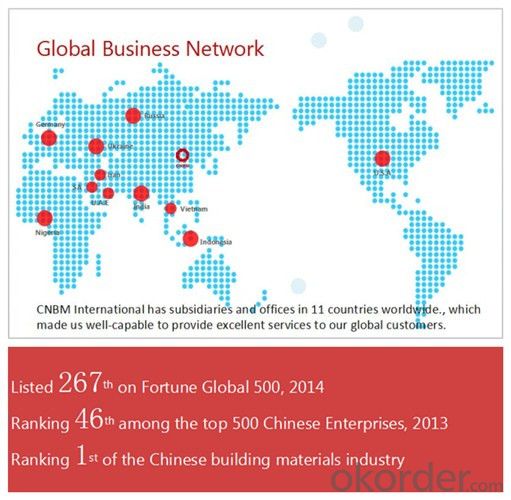

CNBM Introduction of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How is special steel used in the production of engine components?

- Special steel is used in the production of engine components due to its exceptional strength, durability, and resistance to heat and corrosion. It is commonly used to manufacture parts such as crankshafts, camshafts, connecting rods, and valves, which are subjected to high stress and temperature conditions. The special steel's properties enable these components to withstand the demanding operating conditions of engines, resulting in enhanced performance, reliability, and longevity.

- Q: How does precipitation-hardening steel achieve high strength through heat treatment?

- Precipitation-hardening steel achieves high strength through a process called heat treatment. This involves heating the steel at a specific temperature to dissolve the alloying elements evenly throughout the metal. The steel is then rapidly cooled, forming a supersaturated solid solution. Subsequent aging or precipitation heat treatment allows tiny particles to precipitate out, strengthening the steel. These fine particles hinder the movement of dislocations, enhancing the steel's strength while maintaining its toughness.

- Q: Can special steel be used in medical applications?

- Yes, special steel can be used in medical applications. Special steel alloys, such as stainless steel, are commonly used in the production of surgical instruments, orthopedic implants, and medical devices due to their excellent corrosion resistance, durability, and biocompatibility properties.

- Q: What are the different types of alloy steel?

- There are several different types of alloy steel, including stainless steel, tool steel, maraging steel, high-strength low-alloy steel (HSLA), and nickel-based alloy steel.

- Q: How does special steel perform in magnetic applications?

- Special steel performs well in magnetic applications due to its high magnetic permeability and low electrical conductivity. This allows it to efficiently conduct and concentrate magnetic fields, making it ideal for various magnetic devices and applications such as transformers, motors, generators, and magnetic sensors. Additionally, special steel can exhibit excellent magnetic properties such as high saturation magnetization and low coercivity, making it capable of generating strong magnetic fields and maintaining magnetization even in challenging conditions.

- Q: What are the different non-destructive testing methods for special steel?

- There are several non-destructive testing methods that can be used to evaluate special steel materials. These methods are designed to detect any flaws or defects in the steel without causing any damage to the material itself. Some of the commonly used non-destructive testing methods for special steel include: 1. Ultrasonic Testing (UT): This method uses high-frequency sound waves to detect internal flaws or defects in the steel. Ultrasonic waves are directed into the material, and the reflected waves are analyzed to identify any discontinuities such as cracks, voids, or inclusions. 2. Magnetic Particle Testing (MT): This technique is primarily used to identify surface defects in steel. A magnetic field is applied to the material, and iron particles are applied to the surface. If there is a defect present, the magnetic field will cause the particles to cluster around the defect, making it visible for inspection. 3. Liquid Penetrant Testing (PT): PT is a widely used method to detect surface defects in special steel. A liquid dye is applied to the steel surface, and after a certain amount of time, excess dye is removed. A developer is then applied, which draws the dye out of any defects, making them visible for inspection. 4. Radiographic Testing (RT): This method involves the use of X-rays or gamma rays to examine the internal structure of special steel. The steel is exposed to radiation, and the resulting image is captured on a radiographic film or digital detector. This method is particularly effective in detecting internal defects such as porosity, inclusions, or cracks. 5. Eddy Current Testing (ECT): ECT is primarily used for surface inspection of special steel. It involves passing an electrical current through a coil that generates a magnetic field. Any variations in the magnetic field caused by defects on the surface of the steel can be detected and analyzed. These non-destructive testing methods provide valuable information about the quality and integrity of special steel materials without causing any damage. By employing these techniques, manufacturers and engineers can ensure that the steel meets the required standards and specifications, thus enhancing safety and reliability in various applications.

- Q: How is special steel used in the production of molds and dies?

- Special steel is used in the production of molds and dies due to its exceptional properties, such as high hardness, wear resistance, and heat resistance. These characteristics make it ideal for shaping and forming various materials, including metals and plastics. Special steel can withstand the high pressures and temperatures involved in the molding and die casting processes, ensuring durability and precision in the production of molds and dies.

- Q: What are the different international trade regulations for special steel?

- Special steel, which is produced for specific applications or industries, falls under the purview of various international trade regulations. These regulations have the objectives of ensuring fair trade practices, protecting domestic industries, and promoting safety standards. The World Trade Organization (WTO) agreements are one of the primary international trade regulations for special steel. The WTO, through agreements like the General Agreement on Tariffs and Trade (GATT) and the Agreement on Safeguards, establishes rules for global trade. These agreements address issues such as tariffs, non-tariff barriers, and safeguard measures that may be imposed on imports of special steel. Another significant regulation is the Harmonized System (HS) codes. These codes provide a standardized system of names and numbers to classify traded products. Special steel is assigned specific HS codes, which enable customs authorities to determine the relevant duties and regulations applicable to these products during import or export. Regional trade agreements (RTAs) also play a role in regulating international trade of special steel. RTAs are agreements between countries or regions that aim to reduce trade barriers and promote economic integration. Examples of such agreements include NAFTA, the EU, and the CPTPP. They often include provisions related to tariffs, technical standards, and trade facilitation for special steel. Furthermore, certain countries may have specific regulations concerning the import or export of special steel. These regulations may encompass licensing requirements, quality standards, safety certifications, or restrictions on certain types of steel. Businesses involved in the trade of special steel must be aware of these country-specific regulations to ensure compliance. In conclusion, the regulations governing international trade of special steel encompass a variety of agreements, codes, and country-specific rules. Adhering to these regulations is crucial for companies engaged in global trade to ensure compliance, avoid penalties, and uphold fair trade practices.

- Q: What are the challenges faced in the manufacturing process of special steel?

- There are several challenges faced in the manufacturing process of special steel. Firstly, the raw materials used in special steel production, such as alloying elements, need to be carefully selected and sourced to ensure high quality and desired properties. Secondly, the melting and casting process requires precise control of temperatures and cooling rates to prevent defects and achieve uniformity. Thirdly, achieving the desired composition and microstructure through heat treatment can be complex and time-consuming. Additionally, maintaining consistent quality throughout the entire production process can be a challenge, as any variation in parameters can result in variations in the final product. Finally, ensuring compliance with stringent industry standards and regulations adds another layer of complexity to the manufacturing process of special steel.

- Q: How does special steel perform in heat treatment applications?

- Special steel performs well in heat treatment applications due to its unique composition and properties. It has a high carbon content, which allows it to be hardened and tempered to achieve desired hardness, strength, and wear resistance. The controlled heating and cooling processes during heat treatment enable the transformation of its microstructure, enhancing its mechanical properties. Special steel also exhibits excellent heat resistance, maintaining its strength and toughness even at elevated temperatures. Overall, special steel is highly suitable for heat treatment applications, providing superior performance and durability.

Send your message to us

Grade SAE 4140 Steel Price Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords