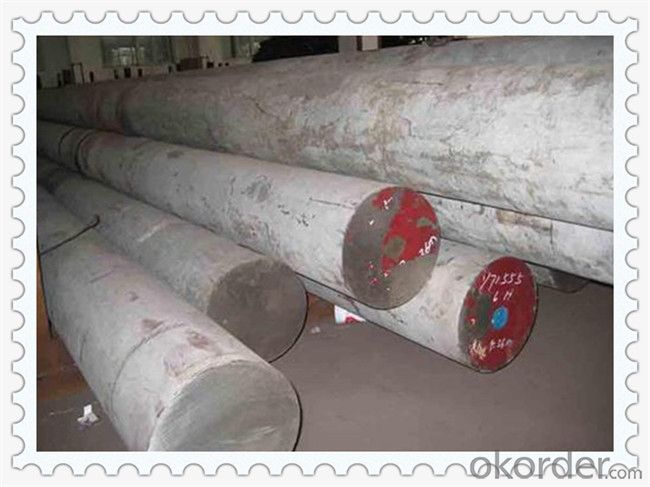

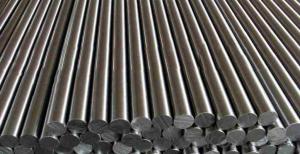

Hot Rolled Alloy Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Alloy Steel Round Bars

1. Commodity: Round steel bar

3. Technical: Hot rolling

2. Length: Min. 5.8meter, according to requirement.

3. Diameter: 16mm-250mm

5. Packing: In Bundle or according to your requirements.

4. Standard: GB/T 3077-1999(42CrMo) ; JIS SCM440; DIN 42CrMo4 ; ASTM 4140 ; BS 708M40

No.1 Rolling Line / Billet Size 150*150mm

16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 |

34 | 35 | 36 | 37 | 39 | 40 | 42 | 43 | 45.6 |

46 | 47 | 52 | 54 | 55 | 56 | 58 | 60 |

No.2 Rolling Line / Billet Size 180*220mm/ 260*300mm

62 | 63 | 64 | 65 | 66 | 67 | 68 | 69 | |

70 | 72 | 73 | 75 | 78 | 80 | 82 | 83 | 85 |

86 | 88 | 90 | 92 | 95 | 100 | 103 | 105 | 110 |

114 | 115 | 120 | 125 | 130 | 135 | 140 | 145 | 150 |

No.3 Rolling Line / Round Billet Size 350mm/450mm/600mm

90 | 95 | 100 | 105 | 110 | 115 | 120 | 125 | 130 |

140 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 |

230 | 240 | 250 |

- Q: What is the difference between a solid steel round bar and a hollow steel round bar?

- A solid steel round bar is a cylindrical metal rod that has a uniform diameter throughout its entire length. It is made of solid steel, meaning it does not have any hollow or empty space inside. On the other hand, a hollow steel round bar also has a cylindrical shape but contains a hollow or empty space within its center. This hollow space can vary in size, depending on the specific design and purpose of the hollow round bar. The main difference between the two lies in their structural integrity and weight-bearing capacity. A solid steel round bar offers greater strength and stability compared to a hollow steel round bar. This is because the solid bar is made of a continuous steel material, making it more resistant to bending, twisting, or deforming under pressure. It is commonly used in applications where high strength and durability are required, such as construction, engineering, and manufacturing industries. In contrast, a hollow steel round bar may have reduced strength and load-bearing capacity due to the presence of the hollow space within. However, the hollow design provides certain advantages in terms of weight, cost, and flexibility. The hollow space allows for a lighter overall weight of the bar, making it more suitable for applications where weight is a critical factor, such as aerospace or automotive industries. Additionally, the hollow space can be utilized for various purposes, such as passing through electrical wires or fluids, providing a channel for ventilation, or even reducing material costs by using less steel. Ultimately, the choice between a solid steel round bar and a hollow steel round bar depends on the specific requirements of the application. If strength and stability are paramount, a solid bar would be the preferred choice. Conversely, if weight reduction, cost-efficiency, or additional functionality is desired, a hollow bar may be more suitable.

- Q: How about tempering No. 45 round bar?

- Quenching and tempering is the double heat treatment of quenching and high temperature tempering, the purpose is to make the workpiece have good comprehensive mechanical properties.

- Q: Can steel round bars be machined using CNC equipment?

- Indeed, CNC equipment is capable of machining steel round bars. By utilizing computer programs to govern the movement of cutting tools, CNC machines can execute a vast array of operations on diverse materials, including steel round bars. These operations encompass turning, milling, drilling, and threading, effectively achieving the desired shape, dimensions, and surface finish. Notably, CNC machines exhibit exceptional repeatability, consistency, and efficiency, rendering them an optimal selection for machining steel round bars in industries such as automotive, aerospace, construction, and manufacturing.

- Q: Which is stronger, steel pipe or round steel? Which is good at bending?

- Of resistance to shearing, of course, of high round steel, generally used with steel tubes (light weight and material saving) for transmitting torque

- Q: What are the advantages of using aluminum-magnesium alloy steel round bars?

- Aluminum-magnesium alloy steel round bars offer several benefits: 1. Lightweight: With its lower density compared to traditional steel, aluminum-magnesium alloy steel is a lightweight material. This is advantageous in industries like aerospace and automotive where weight reduction is crucial. It improves fuel efficiency and increases payload capacity. 2. Corrosion resistance: Aluminum-magnesium alloy steel has excellent resistance to corrosion. The addition of magnesium enhances its ability to withstand harsh environments, including moisture, chemicals, and saltwater. It is ideal for marine applications and areas with high humidity or corrosive atmospheres. 3. High strength-to-weight ratio: Despite being lightweight, aluminum-magnesium alloy steel is highly strong. It offers a superior strength-to-weight ratio compared to other materials, allowing for the construction of durable structures. This is valuable in applications like construction where both strength and weight are important factors. 4. Excellent machinability: Aluminum-magnesium alloy steel is easy to machine, making it suitable for a variety of fabrication processes. It can be cut, drilled, and welded with ease, enabling efficient manufacturing and assembly. This saves time and costs while allowing for complex designs and customization. 5. Thermal conductivity: Aluminum-magnesium alloy steel has excellent thermal conductivity, facilitating efficient heat transfer. This property is valuable in applications such as heat exchangers, cooling systems, and electrical conductors. It prevents overheating and improves overall performance. 6. Recyclability: Aluminum-magnesium alloy steel is highly recyclable, making it an environmentally friendly choice. It can be melted down and reused, reducing the need for raw materials and minimizing waste. Recycling aluminum-magnesium alloy steel requires less energy compared to primary production, making it a sustainable option. In conclusion, the advantages of aluminum-magnesium alloy steel round bars make it a versatile and cost-effective material for various applications. Its lightweight nature, corrosion resistance, high strength-to-weight ratio, excellent machinability, thermal conductivity, and recyclability make it a preferred choice in industries where these properties are essential.

- Q: What are the different cutting methods used for steel round bars?

- The cutting of steel round bars can be done using various methods, depending on the specific requirements and available tools. Here are some commonly used cutting methods: 1. Sawing: Traditional sawing using a saw blade is a cost-effective and simple method suitable for smaller diameter round bars. 2. Abrasive Cutting: When cutting thicker and harder steel bars, abrasive cutting with an abrasive wheel or disc proves to be highly effective. It is often used in industrial applications where precision and speed are crucial. 3. Plasma Cutting: This thermal cutting method involves using a high-velocity jet of ionized gas to melt and remove the metal. It is suitable for cutting steel bars of different thicknesses and is renowned for its speed and precision. 4. Laser Cutting: Laser cutting is an efficient and precise method that utilizes a high-powered laser beam to melt and vaporize the metal. It is commonly employed for cutting intricate shapes and patterns in steel round bars. 5. Waterjet Cutting: Waterjet cutting utilizes a high-pressure stream of water mixed with an abrasive material to cut through steel bars of varying thicknesses and types. It is a versatile method. 6. Shearing: This cutting method involves using specialized machine blades to swiftly and accurately cut smaller diameter round bars. When considering the cutting method for steel round bars, it is crucial to carefully assess the project's specific requirements and consult with experts to determine the most suitable approach.

- Q: Can steel round bars be used in the manufacturing of shafts?

- Yes, steel round bars can be used in the manufacturing of shafts. Steel round bars are often used as raw materials for shaft manufacturing due to their high strength, durability, and excellent mechanical properties. The round shape of the bar allows for easier machining and forming processes, making it suitable for creating shafts of various sizes and lengths. Additionally, steel round bars can be heat treated to enhance their hardness, strength, and wear resistance, further improving their suitability for shaft applications.

- Q: What are the advantages of using carbon-manganese alloy steel round bars?

- Carbon-manganese alloy steel round bars offer numerous benefits: Firstly, they provide exceptional strength and durability, making them ideal for demanding applications. These bars can withstand heavy loads and resist deformation, ensuring long-lasting performance. Secondly, they possess excellent impact resistance, making them highly suitable for situations where there is a risk of impact or sudden loads. This feature helps to prevent fractures or breakages, enhancing safety and reliability. Furthermore, carbon-manganese alloy steel round bars have good weldability, allowing for easy fabrication and joining. They can be easily welded using common techniques, making them versatile and cost-effective for various construction projects. In addition, these bars exhibit good corrosion resistance, making them suitable for use in environments where exposure to moisture or corrosive substances is a concern. This property helps to extend the lifespan of the bars and reduces the need for frequent maintenance and replacement. Moreover, carbon-manganese alloy steel round bars are generally more cost-effective compared to other high-strength steel options. They offer a balance between strength and affordability, making them a cost-efficient choice for applications where high-strength materials are needed without excessive costs. Lastly, these bars are relatively easy to machine, allowing for precise shaping and finishing. This feature makes them suitable for applications that require complex or custom designs. Overall, the advantages of using carbon-manganese alloy steel round bars include their strength, durability, impact resistance, weldability, corrosion resistance, cost-effectiveness, and machinability. These properties make them a reliable and versatile choice for a wide range of applications in industries such as construction, automotive, and manufacturing.

- Q: How do steel round bars compare to wrought iron bars?

- Steel round bars and wrought iron bars have several differences that set them apart. Firstly, steel round bars are made from an alloy of iron and carbon, whereas wrought iron bars are composed of pure iron with a low carbon content. This difference in composition leads to varying properties. Steel round bars are known for their strength and durability, making them suitable for a wide range of applications, including construction, manufacturing, and engineering. On the other hand, wrought iron bars are softer and more malleable, allowing them to be easily shaped and formed into intricate designs. This characteristic makes wrought iron bars popular in decorative applications such as gates, fences, and ornamental pieces. Another difference lies in their manufacturing processes. Steel round bars are typically produced through hot rolling, which involves heating the steel billet and passing it through a series of rollers to shape it into the desired round bar form. In contrast, wrought iron bars are made through a labor-intensive process called blacksmithing. This involves heating the iron and repeatedly hammering it to remove impurities and create a fibrous structure, resulting in its characteristic grainy appearance. In terms of cost, steel round bars are generally more affordable compared to wrought iron bars. The manufacturing process for steel is more streamlined and efficient, leading to lower production costs. Wrought iron bars, on the other hand, require more time and labor, making them more expensive. Finally, when it comes to corrosion resistance, steel round bars have an advantage. Steel can be further alloyed with elements such as chromium, nickel, and molybdenum to enhance its resistance to rust and corrosion. This makes steel round bars suitable for outdoor applications where they may be exposed to moisture and harsh environmental conditions. Wrought iron bars, although they possess some level of corrosion resistance, are more prone to rusting and require regular maintenance to prevent deterioration. In conclusion, steel round bars and wrought iron bars differ in terms of composition, strength, manufacturing process, cost, and corrosion resistance. The choice between the two will depend on the specific requirements of the application, with steel round bars being favored for their strength and affordability, while wrought iron bars are often chosen for their malleability and decorative appeal.

- Q: Can steel round bars be used for making cooling system components?

- Yes, steel round bars can be used for making cooling system components. Steel is a versatile and durable material that can withstand high temperatures and pressures, making it suitable for cooling system applications. Steel round bars can be machined to specific dimensions and shapes required for different cooling system components such as pipes, fittings, valves, and heat exchangers. Additionally, steel has excellent thermal conductivity, allowing for efficient heat transfer in cooling systems. However, it is important to consider the specific requirements of the cooling system and consult with engineers or professionals in order to select the appropriate grade of steel and ensure compatibility with other system components.

Send your message to us

Hot Rolled Alloy Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords