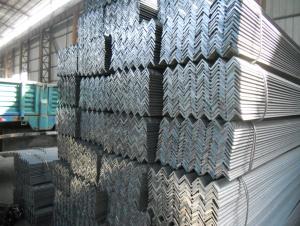

ANGLE BAR

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | | ||||

C | Mn | S | P | Si | | ||

| | |||||||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | | ||||

Thickness (mm) | | ||||||

≤16 | >16--40 | >40--60 | >60--100 | | |||

≥ | | ||||||

|

|

|

|

|

| | |

Q235 | B | 235 | 225 | 215 | 205 | | |

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | | |||

Thickness (mm) | | ||||||

| ≤16 | >16--40 | >40--60 | >60--100 | | ||

≥ | | ||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel angles be used in marine applications?

- Yes, steel angles can be used in marine applications. They are commonly used in the construction of ships, offshore platforms, and marine structures due to their strength, durability, and corrosion resistance properties. Steel angles provide structural support and stability in marine environments, making them suitable for various applications in the maritime industry.

- Q: What are the different types of steel angles used in shelving units?

- There are several different types of steel angles that are commonly used in shelving units. Some of the most common types include: 1. L-shaped angles: These are the most basic type of steel angles used in shelving units. They have a 90-degree angle and are commonly used to create the frame of the shelving unit. 2. Slotted angles: Slotted angles are similar to L-shaped angles but have holes or slots along their length. These holes allow for easy adjustment of the shelving height and allow for flexibility in configuring the shelving unit. 3. Equal angles: Equal angles have equal length legs and are commonly used in shelving units where the shelves are made of steel or other heavy materials. These angles provide additional strength and support to the shelves. 4. Unequal angles: Unequal angles have legs of different lengths. They are often used in shelving units where the shelves are made of lighter materials such as wood or plastic. The unequal angles provide stability and prevent the shelves from sagging under the weight of the items placed on them. 5. Slotted equal angles: Slotted equal angles are similar to slotted angles but have equal length legs. These angles are commonly used in shelving units where adjustability is required, but the added strength of equal angles is also needed. Overall, the choice of steel angles for shelving units depends on the specific requirements of the unit, such as load capacity, adjustability, and material used for the shelves.

- Q: What are the common applications of steel angles?

- Steel angles find extensive use in a multitude of applications owing to their adaptability and robustness. Some prevalent applications of steel angles encompass: 1. Supporting structures: Steel angles are frequently employed as integral components in the construction of buildings and bridges, providing the required fortitude and stability. They serve as beams, columns, and braces, bolstering the structure. 2. Construction: Steel angles play a crucial role in construction endeavors, facilitating the creation of frameworks, supports, and reinforcements. They are adept at forming wall corners, bolstering roof trusses, and enhancing the durability of concrete structures. 3. Machinery and equipment: In the manufacturing of machinery and equipment, steel angles are extensively employed as brackets, frames, and supports for various components. Their utilization ensures stability and structural integrity within these machines. 4. Industrial shelving and racks: Industrial shelving units and racks are frequently constructed using steel angles. These angles provide a robust and dependable structure capable of accommodating heavy items while optimizing storage space. 5. Agricultural equipment: Steel angles are integral to the fabrication of agricultural machinery and equipment, often serving as frames, supports, and brackets for farm implements like plows, cultivators, and harvesters. 6. Fencing and barriers: Steel angles find application in the construction of fences, barriers, and handrails, where their strength and durability are paramount. These angles imbue the structures with the resilience to endure harsh weather conditions and offer enhanced security. 7. Transportation: Vehicles and transportation equipment rely on steel angles during their construction. These angles can be found in truck beds, trailers, and railings, providing the necessary strength and stability for the safe transportation of goods and passengers. 8. Decorative and architectural applications: Steel angles are often utilized for decorative and architectural purposes. They seamlessly integrate into building facades, staircases, and ornamental metalwork, imparting a contemporary and sleek aesthetic while providing structural support. In conclusion, the versatility, durability, and strength of steel angles render them indispensable across a vast array of industries, serving a multitude of purposes.

- Q: What are the different types of steel angles used in material handling equipment?

- Material handling equipment commonly utilizes various types of steel angles to provide structural support and reinforcement. These angles are crucial in maintaining stability and strength. One frequently used steel angle in material handling equipment is the equal angle. This angle possesses equal sides and is often employed to construct frames or supports in conveyors, cranes, and lifting devices. Its stability and structural integrity make it a dependable choice for heavy-duty applications. Another type of steel angle found in material handling equipment is the unequal angle. As its name suggests, this angle has sides of unequal length, with one side being longer than the other. It is often utilized in equipment that requires a specific angle or slope, such as ramps, inclined conveyors, or equipment with adjustable height mechanisms. The unequal angle permits customization and flexibility in design. Moreover, there are specialized steel angles with specific profiles designed for unique applications in material handling equipment. For instance, the L-shaped angle is frequently used as a corner bracket or reinforcement in shelving units, racks, and pallets. On the other hand, the T-shaped angle is commonly employed as a support or bracket for attaching additional components or accessories to the equipment. It is important to note that the selection of steel angles in material handling equipment depends on various factors, including weight capacity, load distribution, environmental conditions, and design requirements. Engineers and manufacturers meticulously evaluate these factors to choose the most suitable steel angle for each specific application, ensuring the equipment's safety, durability, and efficiency.

- Q: Can steel angles be used in the construction of industrial chimneys?

- Yes, steel angles can be used in the construction of industrial chimneys. Steel angles provide structural support and stability to the chimney, making them a common choice in industrial construction projects.

- Q: How do steel angles perform under cyclic loading?

- Steel angles perform well under cyclic loading due to their high strength and stiffness. They are capable of resisting repeated loading and can withstand significant stress and strain without experiencing fatigue failure. The structural design of steel angles allows them to efficiently distribute and dissipate the applied loads, making them reliable and durable in cyclic loading conditions.

- Q: Are steel angles suitable for historical restoration projects?

- Historical restoration projects can benefit from the suitability of steel angles. These versatile and durable materials are ideal for enhancing structural support and reinforcement in historic buildings. In fact, they can be employed to revive or duplicate original architectural elements like window frames, ornamental railings, and decorative features. Moreover, steel angles can be custom-made to perfectly match the original design, seamlessly merging with the existing structure. Nonetheless, it is crucial to take into account the specific demands and regulations of the historical restoration project, as some preservation authorities may impose limitations on the use of contemporary materials. Seeking guidance from experts in historical restoration and obtaining the necessary approvals will guarantee the appropriate and effective utilization of steel angles in preserving the historical integrity of the building.

- Q: Can steel angles be used for support structures in sports arenas or stadiums?

- Sports arenas or stadiums can make use of steel angles for their support structures. The construction industry often opts for steel angles due to their strength, durability, and versatility. These angles are particularly suitable for support structures as they can handle heavy loads and offer stability. In the realm of sports arenas or stadiums, steel angles serve various purposes. They can be utilized to support the roof, create seating platforms, construct staircases, and form the framework for walls and partitions. Architects and engineers can design custom support structures that meet the specific requirements of each sports arena or stadium, thanks to the flexibility of steel angles. Moreover, steel angles can be easily fabricated and joined, which makes them ideal for constructing complex support systems. Their ability to resist bending, twisting, and compression ensures the overall stability and safety of the structure. Additionally, steel is an environmentally friendly material as it is 100% recyclable. By using steel angles for support structures, the construction industry can contribute to reducing carbon emissions and promoting a more sustainable future. In conclusion, steel angles are a dependable and efficient choice for support structures in sports arenas or stadiums. Their strength, durability, versatility, and sustainability make them an excellent option for ensuring the safety and stability of these large-scale structures.

- Q: Can steel angles be used for manufacturing furniture?

- Yes, steel angles can be used for manufacturing furniture. They provide structural support and can be used to create strong and durable furniture pieces. Steel angles are commonly used in industrial and modern furniture designs due to their sleek and minimalist aesthetic.

- Q: Can steel angles be used in modular building systems?

- Indeed, modular building systems can utilize steel angles. Due to their strength and versatility, steel angles are frequently employed in construction. These angles contribute structural support and stability to the building system. In the realm of modular construction, steel angles serve as framing members, connectors, or reinforcements, depending on the specific design requirements. They can effortlessly be attached and integrated into the modular system, enabling efficient and cost-effective construction. Furthermore, steel angles possess durability and resistance to diverse environmental factors, rendering them suitable for modular buildings that must endure various conditions. All in all, steel angles constitute a dependable and pragmatic option for modular building systems.

Send your message to us

ANGLE BAR

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords