Hot Rolled Steel Coils with Standard ASTM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rolled to its final dimensions while it’s hot enough to scale, our hot-rolled steel is an amalgamation of the various qualities of steel.

It can be in the form of plates, sheets and coils.

Our hot rolled steel sheets and coils are applied to wide range of uses such as automobile, electrical appliance, machinery manufacturing, container manufacturing, shipbuilding bridge, pipeline, and receive high acclaim from our customers for its excellent quality.

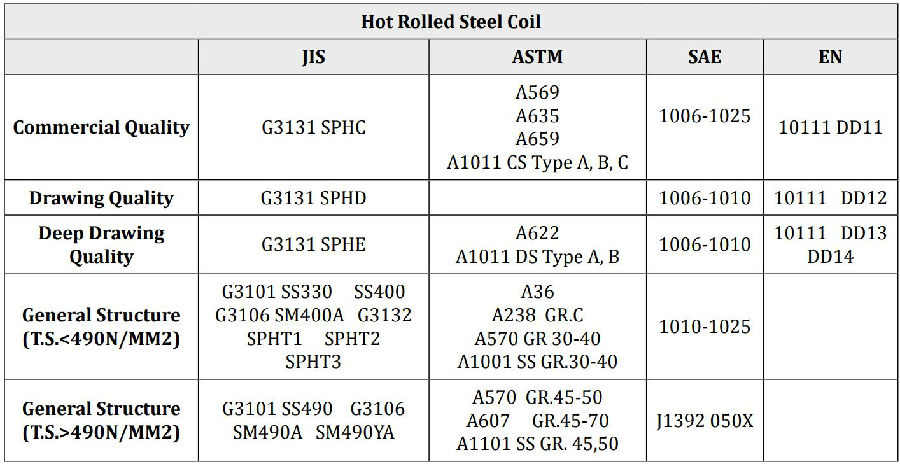

Specification of Hot Rolled Steel Coils with Standard ASTM

Standard:ASTM, JIS, GB

Steel Grade:Q235

Technique:Hot Rolled

Packing:in Bundles or Coils

STANDARD & GRADE

APPLICATION

Automobile, Electrical Appliance, Machinery, Transport Equipment, Steel Structure, Pressure Vassel Tank, Welded Pipe, Bridge, Container Shipbuilding.

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size.

And we will consider to give more discount if you make big order like 1000 tons and more.

Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC.

We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;

We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: In construction, what types of stress require steel to be placed in footings?

- Bending moment , shear stress and punching stresses

- Q: I bought a steel pendant on eBay, but it turned out to be too shiny.I've read on a couple forums that if I leave it soaked in urine for 2 days, it will get duller.Now, if it really does get duller, will the pendant get rusty afterwards?So is the shiny surface the only thing that prevents it from rusting?Any simple, non-urine ideas on how to make it duller are welcome too.Thanks!

- Stainless steel will rust under proper conditions. I live on a boat on salt water, trust me. If the urine works it won't be prone to rusting any more than before. It's not the shine that inhibits rusting with stainless steel, it the % of carbon in the steel, compared to regular steel. IF the urine works it's because it is acidic (a mild acid). Wash it with a small brush and some baking soda to neutralize the acid when your done. A much stronger acid would be swimming pool acid. (Muriatic acid) but be careful you might test a spot with a Q tip on the back. If you try Muriatic acid it would take seconds.Then wash in baking soda water to remove all acid.. SS

- Q: Can steel coils be coated with anti-glare materials?

- Yes, steel coils can be coated with anti-glare materials.

- Q: What are the common coil surface finish standards?

- The common coil surface finish standards include mill finish, brushed finish, polished finish, and embossed finish.

- Q: So I'm trying to decide which is better. I've always had aluminum on my 6 yr old tb gelding as I do hunters on him. He's never had steel on but I've recently moved and the shoer here is more expensive. So is aluminum really worth the extra cash to keep him light on his feet or is steel really not that much different?

- It really depends on your horse. If you horse is a good mover, and average weight steel shoe shouldn't make much of a difference. If the horse is a mediocre mover, sometimes the added weight will make it move worse. You should also understand that one steel shoe is not like another steel shoe- they come in different widths of web and thickness of steel. Some horses that don't do well in regular shoes do better in a light rim shoe or training plate. Discuss your concerns with your farrier, but he/she doesn't have a crystal ball. You may just have to try steel for a cycle and see how your horse does. When I am shoeing a horse that needs lighter weight steel, I tend to use either St. Croix's Lite Rim shoe or steel Concord training plate, or Kerckaert's DR training plate or the Triumph Lite steel shoe. All of these shoes are light weight, have decent traction and good break over.

- Q: What are the different types of steel coil surface treatment options?

- There are several types of steel coil surface treatment options, including galvanizing, painting, chromating, and pickling. Galvanizing involves coating the steel with a layer of zinc to protect it from corrosion. Painting involves applying a layer of paint to enhance the appearance and provide additional protection. Chromating is a chemical process that forms a thin layer of chromate on the surface to improve corrosion resistance. Pickling involves removing impurities and scale from the steel surface using an acid solution.

- Q: What are the common packaging defects in steel coils?

- Steel coils can have various packaging defects. These include edge damage, rust or corrosion, coil slippage, coil damage during handling, inadequate protection against impacts, improper coil strapping or banding, and insufficient labeling or identification. When the edges of the steel coil are not properly protected or wrapped, it can lead to dents, scratches, or deformities. This compromises the coil's integrity and can result in reduced performance or structural issues. If steel coils are not adequately protected during packaging, they can be prone to rust or corrosion. Moisture or harsh environmental conditions can cause oxidation, resulting in rust spots or widespread corrosion. This weakens the steel and makes it less suitable for its intended use. Improper packaging can cause the coils to shift or slip within the packaging material during handling or transportation. This can lead to misalignment, deformation, or interlocking, making it difficult to separate or use the coils effectively. Rough handling, improper lifting techniques, or inadequate support can cause mechanical damage to the steel coils. This can result in dents, scratches, or more severe structural damage, impacting their functionality or performance. Steel coils need sufficient protection against impacts during transportation or storage. Insufficient padding or cushioning can lead to deformities, dents, or fractures in the coil due to impacts or collisions. If the strapping or banding used to secure the steel coils is not properly applied or tightened, it can cause coil slippage or even complete unraveling of the packaging. This creates a tangled mess of steel coils, making them difficult to handle, transport, or use. Proper labeling and identification are crucial for efficient handling, storage, and tracking of steel coils. Inadequate or incorrect labeling can cause confusion, delays, or even loss of the coils during transportation or storage. To prevent these packaging defects, it is important to follow proper guidelines, use appropriate materials, provide adequate protection, and ensure proper labeling and identification of steel coils. Regular inspections and quality checks throughout the packaging process can help identify and rectify any defects before shipping or use.

- Q: What is the difference between hot-rolled and cold-rolled steel coils?

- The main difference between hot-rolled and cold-rolled steel coils lies in the production process. Hot-rolled steel coils are made by heating the steel above its recrystallization temperature, causing it to become malleable and allowing it to be rolled into the desired shape. This process results in a thicker and less precise product with a rough surface. On the other hand, cold-rolled steel coils are made by cooling the hot-rolled steel and then passing it through rollers at room temperature. This process enhances the steel's strength, durability, and dimensional accuracy, resulting in a thinner and smoother product that is ideal for applications requiring precision.

- Q: Can steel coils be coated with thermally insulating materials?

- Yes, steel coils can be coated with thermally insulating materials.

- Q: How are steel coils packaged for shipping?

- Steel coils are typically packaged for shipping by placing them on wooden or steel pallets, securing them with steel bands or straps, and covering them with protective wrapping such as plastic or waterproof paper. This packaging ensures the coils remain stable, protected from corrosion, and are easy to handle and transport.

Send your message to us

Hot Rolled Steel Coils with Standard ASTM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords