Hot Dipped Galvanized Steel Coil China Factory Price DX51 DZ100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Hot Dipped Galvanized Steel Coil DX51 DZ100 :

Plain galvanized sheets are used for automotive body building, panels, electrical appliances like refrigerator, washing machine, and use for advertisement panels. Etc.

The use of galvanized sheets improves paint ability and corrosion resistance and aesthetic looks.

We provide our customers with an assortment of corrugated sheets, galvanized corrugated sheets and galvanized plain sheets. These sheets are manufactured using premium quality material which provides high tensile strength and makes them seepage resistant. GC sheets prove to be a cost effective solution for various construction purposes such as roofing, side-walls, partitions and panels.

2.Main features of Hot Dipped Galvanized Steel Coil DX51 DZ100:

With excellent cold-rolling steel strips as a base material, it has the advantages of

.Not easily rust; acid resistance and corrosion resistance;

.Widely used in light and heavy industry, food making, architecture, shipping, paper and medicine industry;

.Large and stable supply capability;

.Prompt delivery and rich experience in exporting.

3.Hot Dipped Galvanized Steel Coil DX51 DZ100 Images:

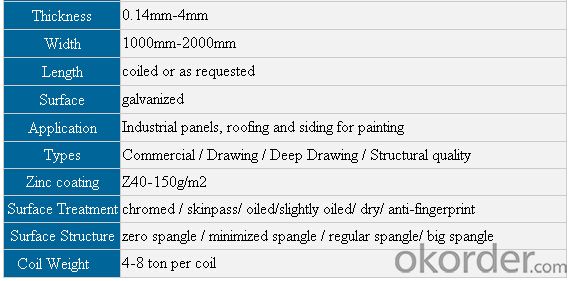

4.Hot Dipped Galvanized Steel Coils for Roofing Sheet -standard Specification:

5.Production Process

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the weight of a standard steel coil?

- The weight of a standard steel coil can vary depending on its dimensions and thickness. However, a typical standard steel coil can weigh anywhere between 3 to 25 tons.

- Q: What is the average cost of shipping steel coils?

- The average cost of shipping steel coils can vary depending on various factors such as the distance, weight, size, and mode of transportation. It is recommended to obtain quotes from shipping companies or freight forwarders to get a more accurate estimate based on your specific requirements.

- Q: i am debating weather to get the hercules rmx or the steel and from what i have read, the only differences between them is the rmx has a sound card (built in interface-to connect to the computer, correct me if im wrong) and that the steel has more effects. however, i cannot find out which effects it has so it would be a big help if someone can answer this for me.thanx

- I guess that since Steel doesn’t have headphones connection and a built-in soundcard, one won’t be able to play a track on one deck and prelisten the track on the other without using an external usb soundcard, right? I was wondering what’s the point in releasing a product like this if you also have to buy a bunch of equipment to be able to do sth “fondamental”: play while preparing your next song. However since the steel is meant for DJ’s who already have a great soundcard, but I don’t see why a Steel+sound card is ONLY for pro’s. Yes it’s designed for pro’s but you can use it as a beginner. Some consoles you also need to consider: Hercules Steel/RMX, Numark OMNI/Steath. It's all personal decision. Peace, Love Happiness

- Q: What is the role of steel coils in the manufacturing of pipes and tubes?

- The manufacturing process for pipes and tubes heavily relies on the crucial role played by steel coils. These coils serve as the primary raw material used in the production of these products. To produce steel coils, molten steel is processed through a series of rolling mills that shape it into flat, thin sheets. These sheets are then wound into coils for the purpose of easy transportation and storage. During the manufacturing process of pipes and tubes, steel coils are unwound, and the flat sheets are subjected to a series of machines and processes. Typically, the first step involves cutting the steel sheets into the desired width and length. This is followed by forming the sheets into a cylindrical shape through a process known as roll forming or continuous forming. The edges of the sheet are welded together to create a seamless pipe or tube. Steel coils offer numerous advantages in the manufacturing process. Firstly, they ensure consistent and reliable quality. The production of coils guarantees uniform thickness and strength throughout the entire length of the sheet, resulting in consistent properties in the final pipes and tubes. This is especially crucial for applications that demand high structural integrity and reliability. Secondly, steel coils facilitate efficient production. The continuous supply of coils ensures a steady flow of raw material, minimizing downtime and enhancing productivity. Coils also enable automated processes, such as roll forming, which can be extremely efficient and cost-effective. Moreover, steel coils provide flexibility regarding size and dimensions. Coils can be manufactured in various widths and thicknesses, enabling manufacturers to tailor the size and specifications of the pipes and tubes to meet their specific requirements. This flexibility empowers the production of pipes and tubes for a wide range of applications, from plumbing and construction to oil and gas pipelines. In conclusion, steel coils are indispensable raw materials in the manufacturing of pipes and tubes. They offer consistent quality, facilitate efficient production, and provide flexibility in terms of size and dimensions. Without steel coils, the production of pipes and tubes would be significantly more challenging and less efficient.

- Q: So finally got around to watching man of steelnow i heard a few times that batman was in iti didn't se him.in the film is it something subtle I've just missed or is he not in it?when i googled it got loads of results for them being together in the new film but nothing about man of steel 2013

- Zod okorder /

- Q: Where can I find a discount online for Stainless Steel Magnetic Knife Rack

- Don’t okorder and read why everyone loves this kitchen accessory so much.

- Q: i wanna know all the similarities between iron and steel

- Simple. Google it

- Q: i mean the properties include the elasticity, impact load and ductility. am doing assignment about the perfect material that should be possessed by spring and i found alloy steel is the perfect and am confused whether stainless steel is the same with alloy steel ?

- Is Stainless Steel An Alloy

- Q: What are the challenges in coil blanking for complex shapes?

- Coil blanking for complex shapes presents several challenges that need to be addressed in order to achieve accurate and efficient results. One significant challenge lies in the precise positioning and alignment of the coil material. Complex shapes often require intricate cutting patterns, and any misalignment or deviation can lead to inaccurate cuts and wasted material. Another challenge is the selection and optimization of the blanking tooling. Complex shapes often require specialized dies and punches, which need to be carefully designed and manufactured to ensure accuracy and consistency. This not only involves the selection of appropriate tooling materials but also the consideration of factors such as cutting forces, wear resistance, and tool life. The complexity of the shapes also poses challenges in terms of material deformation and springback. During the blanking process, the material undergoes various deformations and stresses, which can cause distortions and dimensional variations in the final product. Achieving the desired shape while minimizing these deformations requires a thorough understanding of material properties and advanced techniques such as compensation and adjustment in the die design. Furthermore, the high-speed nature of coil blanking for complex shapes can lead to increased vibration and noise levels. The dynamic forces involved in cutting intricate shapes can result in tool chatter and excessive noise, which not only affects the quality of the cut but also the overall operational efficiency. Implementing effective damping and vibration control measures, such as tool coatings and optimized cutting parameters, is crucial to mitigate these challenges. Lastly, the complexity of the shapes can also impact the overall production efficiency. Complex shapes often require longer tool setup times and more frequent tool changes, which can lead to increased downtime and reduced productivity. Additionally, the intricate nature of the cuts may require multiple passes or additional machining operations, further adding to the production time and complexity. To overcome these challenges, manufacturers need to invest in advanced technologies, such as computer-aided design and simulation software, to optimize the blanking process. Additionally, continuous research and development efforts focused on improving tooling materials, cutting techniques, and process control can help address the challenges associated with coil blanking for complex shapes.

- Q: steel welding with ms steel iron

- Welding austenitic stainless steels to carbon and low alloy steels are established methods in the process and construction industries. Dissimilar metal welds involving stainless steels can be done using most full fusion weld methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas). Weld procedures using filler (consumable) enable better control of joint corrosion resistance and mechanical properties. In selecting the weld filler, the joint is considered as being stainless, rather than the carbon steel. Over-alloyed fillers are used to avoid dilution of the alloying elements in the fusion zone of the parent stainless steel.

Send your message to us

Hot Dipped Galvanized Steel Coil China Factory Price DX51 DZ100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords