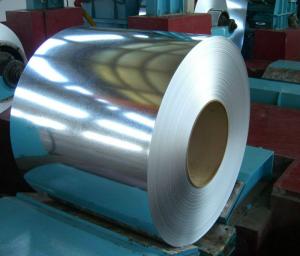

cold rolled steel coils for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SPCC cold rolled steel coil

1) Product Name: Cold rolled Steel Coil/sheet/strip

2) Thickness: 0.4mm-3.0mm

3) Width: 600mm-2000mm

4) Length: As requested

5) Width tolerance: different as per different width

6) Thickness tolerance: different as per different thickness

7) Weight: According to the different requirement

8) Packing: Mill standard export packing in bundles

9) Country of Origin : China

10)Standard: AISI, ASTM29, DIN16723, EN10130, JIS, GB

11)Grade: SPCC, SPCD, SPCE, SPCH, ST12-15, DC01-06, Q195A-Q235A

12)Width: 600-2000mm (general width: 1000mm, 1250mm, 1500mm)

13)Application:

1.For the further producing of hot dip galvanized steel products

2.Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

14)Packing: Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from

15)Payment term: L/C, T/T

16)Delivery date: 15-30 days

17)General Specification:

Classification | Designation | Characteristics | Main applications |

Commercial quality | SPCC SPCCT | Commercial quality suitable for bending fabrication and simple forming; this is thetype in greatest demand. | Refrigerators, cabinets, power distribution baords and drums. |

Drawing quality | SPCD | Drawing quality second only tothat of SPCEN. Excellent uniformity. | Automobile floor and roof panels. |

Deep-drawing quality | SPCE SPCF | Deep-drawing quality.With metallurgically controlled grain size, it retains its beautiful finish even after being deep-drawn. | Automobile fenders and quarter panels |

Extra deep-drawing quality | SPCG | Extra-low-carbon steel sheets with highest workability | Automobile internal panels and deep-drawn parts |

- Q: What are the different types of steel coil packaging materials used during processing?

- There are several types of steel coil packaging materials commonly used during processing, including but not limited to, steel strapping, plastic strapping, stretch film, shrink film, steel coil covers, and wooden crates.

- Q: I looking at replacing a few of the panels on my car with either Carbon Fiber or High Tensile Steel to shave off some weight and increase mpg and take some time off my quarter mile. Which is better: Carbon Fiber or High Tensile Steel?

- Because no matter how hard the helmet is it can not prevent brain damage from your brain slapping the inside of your skull. If the helmet was able to absorb the energy from an impact and prevent you brain from moving inside your skull it would have to be huge and everyone would look like bubble heads riding on bikes. The sides would have to be around 12 inches thick on each side and top to provide that much protection and would probably break your neck if you were in a wreck. Hope I have been helpful.

- Q: How are steel coils inspected for impact resistance using impact testers?

- Steel coils are inspected for impact resistance using impact testers, which are specially designed machines used to assess the ability of the steel coils to withstand impacts. The process involves subjecting the steel coils to controlled impacts and measuring the extent of deformation or damage caused by the impact. Firstly, the steel coils are securely placed on the impact tester, ensuring that they are in the correct position and orientation. The impact tester is equipped with a striking element, such as a pendulum or a falling weight, which is designed to deliver a specific amount of force upon impact. The striking element is carefully aligned with the steel coil to ensure accurate and consistent testing. Once everything is set up, the impact tester is activated, and the striking element is released to impact the steel coil. The force of the impact is carefully controlled and measured to ensure consistency across multiple tests. The impact tester records various parameters during the impact, including the force applied and the duration of the impact. After the impact, the steel coil is carefully examined for any visible deformation or damage. This can include checking for dents, cracks, or any other signs of structural compromise. The extent of the deformation or damage is recorded and compared to predetermined acceptance criteria to determine whether the steel coil passes or fails the impact resistance test. Impact testers can be equipped with various sensors and cameras to capture additional data during the testing process. High-speed cameras can be used to record the impact in slow motion, allowing for a detailed analysis of the coil's behavior during the impact. Strain gauges can be attached to the steel coil to measure the strain and stress experienced during the impact. Overall, the use of impact testers provides a reliable and standardized method for inspecting the impact resistance of steel coils. By subjecting the coils to controlled impacts and carefully measuring the extent of deformation or damage, manufacturers can ensure that their steel coils meet the required impact resistance standards for various applications.

- Q: I bought stainless steel appliances a year ago. I have two kids who like to put their hands all over the fridge and they always leave dirty marks all over it. I bought stainless steel cleaner but it doesn't do a good enough job. Anyone know any other cleaning remedies?

- I have a stainless steel cooker which is a nightmare. I've also tried everything but find the only thing that works for me is to wipe over with a damp cloth then immediately dry it with a dry cloth.

- Q: I received a very nice set of stainless steel cookware as a wedding gift. While very pretty, Im finding them almost useless for cooking. Everything sticks, they're difficult to clean, and Im using my old non-stick pans instead. Should I simply leave the stainless out for decortive purposes, or are stainless steel pans better for some applications?

- I can't understand why you're having difficulty. My pans are as good as the day they were bought.I would never return to non-stick after having my stainless steel pans! Non stick coatings come off in the food-yuk! What are you cooking in them? Are you trying to wash them in the dishwasher? That never works well. I always put water in mine if I've done a custard or stew, beans or things like that, for a little soak before washing by hand in hot soapy water. They really are great even when I have burnt something, because you can scrape the burn with a sharp implement and you do no damage at all to the pan. I highly recommend them.

- Q: How long do steel coils typically last?

- Steel coils typically last for decades. The lifespan of steel coils can vary based on several factors including the quality of the steel used, the level of maintenance and care, and the specific application they are utilized in. Generally, steel coils are designed to be durable and resistant to corrosion, ensuring a long lifespan. With proper care, regular maintenance, and adherence to recommended usage guidelines, steel coils can last anywhere from 20 to 50 years or even longer. However, it is important to note that the lifespan can be influenced by external factors such as exposure to harsh environments, extreme weather conditions, and the level of stress or load they are subjected to.

- Q: How are steel coils used in the production of steel springs?

- Steel coils are used in the production of steel springs as they are rolled into a specific shape and size, providing the necessary strength and flexibility required for springs. These coils are then cut and formed into the desired spring shape, allowing them to store and release energy efficiently.

- Q: I'm going to buy a guitar for beginners and i wondered what strings are better steel or nylon?

- I urge you to read the answer from OU again and ignore the others - who obviously haven't got the first clue of what they're talking about. You pick the guitar for the type of music (and sound) you're after. You can play basically everything on a steel string that you can on a nylon string, plus a whole lot more... And no, a classical guitar is NOT easier to play than a well adjusted steel string with light strings - in fact it's the opposite. A classical guitar has a wide, flat fingerboard, something which makes chords much harder to play. Furhermore, the scale is longer (the scale is the distance between the nut and bridge - the length of the vibrating string if you will). This longer scale increase the distance between the fret (increasing the reach), and also increase the string tension. Finally, the action (string height) is larger on a classical/nylon string guitar as opposed to a steel string guitar which has been properly adjusted. Most guitars off the shelf have an inferior set up for a beginner, and this is why many have this funny idea that a steel string is much harder to play. You may also want to check out guitar body sizes (steel string) that is smaller than the large Jumbo or Dreadnought varieties. In essence, if you play classical music, or classical finger style guitar - choose a nylon string instrument. If not, then get a steel string and have it properly adjusted. Make sure you try out a lot of models as the necks, bodies, woods etc, differ a lot.

- Q: given the buoyant economic growth of india, what you guys think about steel industry? what can be the major issues in this industry in the coming days

- Since2003, India has been the largest sponge iron producer in the world. In 2005, out of total global production of 56.05 mt of sponge iron, India produced around 11.1 mt (19.8%). In line with production target of 110 mt of steel (National Steel Policy) by FY20, many steel producers have announced their capacity expansion plans by signing MOUs with various state governments like Chattisgarh, Orissa and Jharkhand. The steel producers are expected to add around 8 mt of capacity by FY 08. CARE estimates that during 2006-09, demand for steel in the domestic market would grow at a CAGR of 8.4%. HR steel because of its widespread applicability is expected to grow at a CAGR of 17.5%. During this period, major demand drivers would be Consumer durables, Automobiles and Construction. Domestically, steel prices of flat products follow the international trend. Globally, steel prices are expected to firm up with continued growth in steel consumption. Further, the winds of consolidation have gathered pace with Arcelor-Mittal merger and latest acquisition of Corus by Tata Steel. The Indian steel industry has announced huge capacity expansions. With commissioning of these capacities demand-capacity ratio is expected to decline in FY 09 due to excess capacity. Will this lead to a drop in prices with commissioning of these capacities? With China and India becoming the focus of major global steel companies, will the consolidation of steel industry in these countries continue? For comprehensive analysis and CARE’s future outlook on the sector, please refer to the exhaustive report on the Indian Steel Industry by CARE Research.

- Q: How do steel coils contribute to the oil and gas industry?

- Steel coils are an essential component in the oil and gas industry as they are used to manufacture various equipment and structures like pipelines, storage tanks, and drilling rigs. These coils provide the necessary strength, durability, and resistance to corrosion required for the harsh operating conditions in the industry. Additionally, steel coils are crucial in the transportation of oil and gas as they are used in the construction of tankers and pipelines, ensuring the safe and efficient movement of these valuable resources.

Send your message to us

cold rolled steel coils for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords