316 Cold Rolled Stainless Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:316

Type:Stainless Steel Sheets

Shape:Rectange

Grade:300 Series

Certification:ISO, SGS, BV

Perforated:Not Perforated

Standard:AISI

Technique:Cold Rolled

Surface Treatment:Bright

Product:316 Cold Rolled Stainless Steel Coil

Surface:2b, No.1, No.4, Ba, Hl, 8k, Polish, Mirror

Thickness:0.1-3mm

Width:10-2000mm

Length:1000-12000mm

Color:Bright White

Edge:Mill Edge and Slit Edge

Stock:in Stock

Package:Seaworthy Standard Package

Delivery:Within 5 Days

Export Markets:Global

Additional Info.

Trademark:TISCO, BAO STEEL, LISCO, JISCO

Packing:Wooden Pallets, Water Proof Papers

Standard:CE, SGS, ISO, BV

Origin:China

Production Capacity:10000 Tons/Month

Product Description

316 cold rolled Stainless steel coil

1. Specification

Thickness: 0.1mm-150mm

Size:1000mm*C

1220mm/1240mm*C

1250mm*C

1500mm/1524mm*C

1800mm*C

a) This is the usual size that in stock.

b) If you have a large quantity we can order as the size you need.

2.stainless steel coil maintenance:

1)Regular cleaning and maintenance

2)Pay attention to prevent the occurrence of the phenomenon of surface scratcges

3)Use soap,weak detergent or warm water to remove surface dust,dirt

4)In addition to the surface of the binder with alcohol or an organic solvent

5)Use neutral detergent or ammonia solution in addition to surface oil

6)With 10% nitric acid,abrasive detergent in addition to the surface of embroide caused by the dirt.

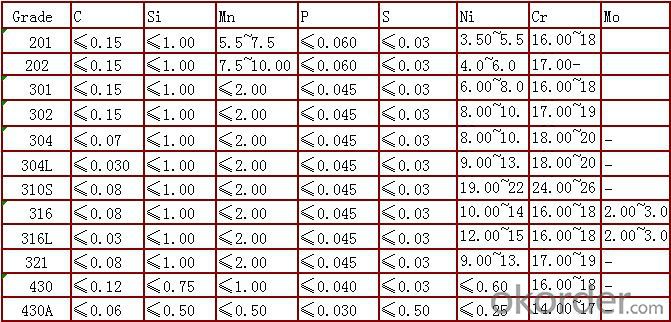

3.Chemical Composition for 316 stainless steel coil

Composition Type 316 (wt %)

Carbon 0.08 max.

Manganese 2.00 max.

Phosphorus 0.045 max.

Sulfur 0.030 max.

Silicon 1.00 max.

Chromium 16.00 - 18.00

Nickel 10.00 - 14.00

Molybdenum 2.00 - 3.00

Iron Balance

4. 316 stainless steel coil--Physical priperties

Also known as titanium steel, 316 stainless steel. Titanium steel grades: 00Cr17Ni14Mo2

Add Mo (2 ~ 3%), excellent resistance to pitting corrosion, high temperature, excellent creep resistance.

Feature

1) cold-rolled product appearance, good gloss, beautiful;

2) the addition of Mo, corrosion resistance, especially resistance to pitting corrosion;

3) excellent high temperature strength

4) Excellent hardening (after processing weakly magnetic)

5) solid solution state non-magnetic;

6) relative to 304 stainless steel, and higher prices.

5.316 Stainless steel coil surface:

2B,BA,Hairline-HL,No.4,brush,8K,Polish,SB,Mirror finish. 6. Packing and Delivery

6. Packing and Delivery

a) Packing: seaworthy wooden pallets,water proof paper,pvc film,interleaving paper,

in 20' or 40' container or as per customers' requirements.

b) Delivery: products in stock can be prepare within 3 days after receiving deposit.

Products as your order can be finished within 15 days under 500 tons.

7.Application of Stainless steel coil:

1)Construction feild,shipping building industry

2)Petroleum and Chemical Industries

3)Food and Mechanical Industries

4)Boiler Heat Exchange

5)Mechinery and Hardware Industries

8.Our advangtages of stainless steel coil:

1) High-prime quality and best price.

2)With rich experience in this line for many years.

3)Professional team and warehouse for stock.

4)It's very important for a company to be honest in the process of trading and so do we.

5)Our products are exported to countries around the world.

- Q: i have been playing with hand me down graphite shaft irons and wedges. i was wondering if someone of my stature (5'3, 90 lbs., 12 years old) should be using steel shafted irons. i can definately swing them im just wondering if they are better for making contact

- Steel will give you more consistency as they don't flex as much as graphite but at the same time are less forgiving. Graphite can give you more flex which increases club head speed for distance but you lose some consistency. I would say stick with your current clubs being your only 12yo and will being a lot in the next 5-6 years. You don't want to be stuck at 17yo and 5'10 swinging clubs that are for someone much shorter.

- Q: i have a white spot on my stainless steel stove, its on the part behind the burners where the oven controls are, does anyone know what it may be and how to remove it. i have tried soap and water and stainless steel cleaner but neither worked. thanks!

- Barkeeper's Friend is the bomb for a metal and fiberglass cleaner, if it can be removed, it will remove it. I have no clue what it is thats on there.

- Q: How are steel coils heat treated?

- Steel coils are heat treated using a process called annealing. Annealing is a heat treatment technique in which the steel coils are heated to a specific temperature and then slowly cooled down. This process helps to relieve any internal stresses within the steel, improve its mechanical properties, and enhance its overall performance. The heating process involves raising the temperature of the steel coils to a critical point, typically between 800°C and 900°C, depending on the specific grade and desired outcome. The coils are then held at this temperature for a specific period of time, allowing for the transformation of the steel's microstructure. Once the desired time has elapsed, the heated steel coils are slowly cooled down in a controlled manner. This slow cooling process is vital as it allows the steel to undergo a gradual transformation, resulting in a more uniform and refined microstructure. This controlled cooling also helps to minimize the formation of internal stresses, which can potentially weaken the steel. The annealing process can be performed in different atmospheres, such as air, nitrogen, or hydrogen. The choice of atmosphere depends on the specific requirements and properties desired for the steel coils. For instance, annealing in a protective atmosphere like nitrogen or hydrogen can help prevent oxidation or decarburization of the steel surface. Overall, heat treating steel coils through annealing is a critical step in enhancing their mechanical properties, improving their formability, and achieving the desired characteristics for various industrial applications.

- Q: How are steel coils shipped internationally?

- To ensure the safe and efficient transportation of steel coils internationally, various methods are utilized. The most commonly employed technique involves container shipping, where steel coils are placed in standard shipping containers. These containers are specifically designed to handle heavy and bulky cargo like steel coils. To load the steel coils into the containers, they are typically stacked horizontally and secured with steel strapping or metal bands to prevent any movement during transit. This ensures stability and minimizes the risk of damage. Additionally, wooden or metal dunnage may be used to separate and secure the coils, further preventing any shifting. Once loaded, the containers are sealed and transported to the port using trucks or trains. At the port, the containers are loaded onto cargo ships utilizing crane or specialized equipment, such as roll-on/roll-off (RO-RO) vessels or semi-submersible ships. These ships provide a protected environment for the steel coils during the journey, shielding them from adverse weather conditions and potential damage. Throughout the voyage, the steel coils are subjected to various safety measures to prevent corrosion and maintain their integrity. These measures include the application of protective coatings, such as oil or special paints, as well as the use of desiccants or humidity control systems inside the containers to regulate moisture levels and minimize the risk of rusting. Upon arrival at the destination port, the containers are unloaded from the ship and transferred to trucks or trains for further transportation to their final destination. At this stage, the steel coils may undergo customs clearance and inspection procedures before being delivered to the intended recipients. In conclusion, the international shipping of steel coils requires careful planning, secure packaging, and the utilization of specialized containers and equipment to ensure their safe and successful transport.

- Q: Is steel cut really better? The nutritional profiles are nealy identical. Which one has the best flavor??Thanks!

- Steel okorder /

- Q: What are the common applications of steel coils?

- Steel coils have a wide range of applications, commonly used in industries such as automotive, construction, manufacturing, and appliances. They are utilized for making various products including automobiles, pipes, electrical appliances, roofing, and packaging materials.

- Q: I had a damascus steel katana made for me and was wondering if I could put gun blue on it to make the steel black and it still work right

- There are many makers that use blue on there Damascus. My question, what the heck are you wanting to mess with the finish for? If you had a true Damascus blade made that that thing cost a fortune, and I don't mean under a grand either. Then there is the question of what it is made from, some steel combinations react well to the gun blue, others not so much. If it is a stainless blade it won't work at all and you shouldn't be using it either. I can tell you, my Damascus blades start at $100 for a small cable knife and go up from there. If you wanted a sword it would push 10 g's easy. None of my customers would mess with the finish, most would cry if it got scratched. If it's has a pretty pattern don't mess with it.

- Q: What are the common coil edge options?

- The common coil edge options include open coil edge, continuous coil edge, and hand-tied coil edge.

- Q: I was wondering whether anyone knew if painted steels rusts at the same speed as steel that isn't painted. Also, does steel rust quicker than aluminium?Thank you

- If the steel is properly prepped when painted, then it would last a long time before any rust or corrosion sets in. This still all depends if the item is subjected to water or salt and if the item you painted is not scratched in any way, once exposed from the paint, the rust will begin rapidly. As far as aluminum, no it will not rust, but you do get aluminum oxidation. It gets a white flakey appearance when it begins to oxidize. Now if you are thinking of painting the rims on a car, i recommend scuffing the rim, priming it, lightly sanding and then paint to the color of choice and for the final touch apply a clear coat on the rims to help avoid the rusting. Use a paint such as rustoleum to prolong the effects of rust settling in. good luck..... good luck.....

- Q: How are steel coils protected from mechanical damage?

- Steel coils are protected from mechanical damage by using various methods such as wrapping them with protective materials like plastic or paper, using suitable packaging and strapping techniques, and storing them in a controlled environment to prevent any potential impacts or collisions.

Send your message to us

316 Cold Rolled Stainless Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords