All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

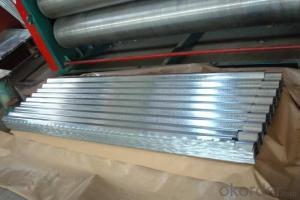

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does hot-rolled steel respond to various types of corrosion?

Hot-rolled steel is generally more susceptible to corrosion compared to other types of steel due to its lower carbon content and lack of protective coatings. It responds differently to various types of corrosion, such as atmospheric, galvanic, and pitting corrosion. In atmospheric corrosion, hot-rolled steel forms a layer of iron oxide on its surface, which provides some protection but can still lead to rusting over time. Galvanic corrosion occurs when hot-rolled steel comes into contact with a different metal in the presence of an electrolyte, causing accelerated corrosion. Pitting corrosion, on the other hand, creates localized pits or holes on the steel's surface, especially in environments with high chloride concentrations. To minimize corrosion, hot-rolled steel often requires additional protective measures such as coatings, paints, or regular maintenance.

What is the role of hot rolled steel in the manufacturing of solar panel support structures?

Hot rolled steel plays a crucial role in the manufacturing of solar panel support structures as it provides strength, durability, and cost-effectiveness. Its ability to be molded into various shapes and sizes makes it ideal for constructing sturdy frameworks that can withstand the weight of solar panels and endure harsh weather conditions. Additionally, hot rolled steel's high tensile strength ensures the stability and longevity of support structures, enabling the solar panels to efficiently capture sunlight and generate renewable energy.

How does hot rolled steel perform in the production of industrial storage tanks?

Hot rolled steel is highly suitable for the production of industrial storage tanks due to its superior strength, durability, and resistance to corrosion. The hot rolling process enhances the steel's structural integrity, making it capable of withstanding high pressure and heavy loads associated with storage tank operations. Additionally, the hot rolled steel's malleability allows for easier fabrication, customization, and welding, enabling efficient construction of storage tanks with complex designs.

Wholesale Hot Rolled Steel from supplier in Canada

With our strong supply chain and global network, we can guarantee timely delivery and competitive pricing for all your Hot Rolled Steel requirements. Our team of experts is always available to provide technical support and assistance, ensuring that you receive the right products for your specific applications.

Furthermore, we prioritize quality control and assurance, ensuring that all our Hot Rolled Steel products meet the highest industry standards. We work closely with our suppliers to ensure consistent quality and performance, giving you peace of mind and confidence in the products you receive.

In addition to our product offerings, we also provide value-added services such as cutting, slitting, and custom fabrication. Our state-of-the-art facilities and experienced staff enable us to meet your unique requirements and specifications, providing you with tailored solutions for your projects.

As a responsible and environmentally conscious company, we are committed to sustainable practices and minimizing our impact on the environment. We adhere to strict environmental regulations and continuously invest in eco-friendly technologies to reduce our carbon footprint.

Partnering with us means gaining access to a reliable and trusted supplier of Hot Rolled Steel in Canada. Our commitment to customer satisfaction, quality products, and exceptional service sets us apart from the competition. Contact us today to discuss your Hot Rolled Steel needs and discover how we can support your business.

Furthermore, we prioritize quality control and assurance, ensuring that all our Hot Rolled Steel products meet the highest industry standards. We work closely with our suppliers to ensure consistent quality and performance, giving you peace of mind and confidence in the products you receive.

In addition to our product offerings, we also provide value-added services such as cutting, slitting, and custom fabrication. Our state-of-the-art facilities and experienced staff enable us to meet your unique requirements and specifications, providing you with tailored solutions for your projects.

As a responsible and environmentally conscious company, we are committed to sustainable practices and minimizing our impact on the environment. We adhere to strict environmental regulations and continuously invest in eco-friendly technologies to reduce our carbon footprint.

Partnering with us means gaining access to a reliable and trusted supplier of Hot Rolled Steel in Canada. Our commitment to customer satisfaction, quality products, and exceptional service sets us apart from the competition. Contact us today to discuss your Hot Rolled Steel needs and discover how we can support your business.