Galvanized Steel Coil with No Spangle in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

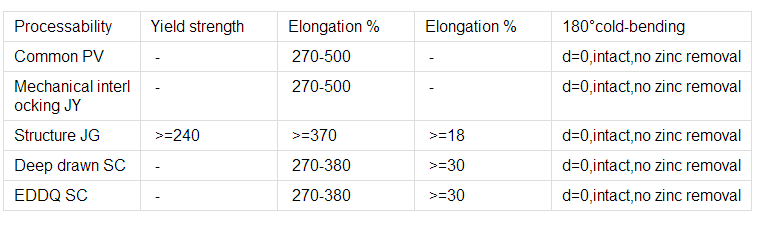

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet :

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:What are the trends and developments in the steel coil industry?

- Some of the current trends and developments in the steel coil industry include increased demand for high-strength and lightweight steel coils due to their use in various industries such as automotive and construction. Technological advancements have also led to the development of advanced coating methods, improving the durability and corrosion resistance of steel coils. Additionally, there is a growing focus on sustainability and environmental friendliness, leading to the use of recycled steel and the implementation of energy-efficient manufacturing processes in the industry.

- Q:How are steel coils used in the production of steel tanks?

- Steel coils are used in the production of steel tanks by being cut and shaped into the desired size and shape of the tank. These coils are typically made of high-quality steel, which provides strength and durability to the tanks. The coils are processed through various manufacturing techniques like rolling, bending, and welding to create the tank's body, ensuring a seamless structure. Additionally, the coils can also be used to create the tank's base, lid, and other components, resulting in a complete and sturdy steel tank suitable for various applications.

- Q:Hi, I have ranch style home. I would like to remove a barring wall, And leave it open it will become a 18' foot 7 inch opening , and I'm interested in installing a steel beam so that i may remove the barring wall that supporting the ceiling and rafters. My house is about 57' feet long 28' feet 7 inch wide and it is 13' feet high from the floor to the top of the roof ridge. I heard there is aluminum beams but I never heard of that, I've only heard of steel beams. I don't want to use wood. I would also like to now how much longer do i need the beam to be the opening would be 18'7 plus the extra that i would need to put on the block wall to hold the beam up, do I make it 2' feet bigger so i can have a foot on each side that would sit on a block wall. or do i need more then that.THanks for your help

- I see steel beams inserted into pockets in concrete foundations, they typically go 6 inches into the pocket. There is other problems with what you want to do. You must support the rafters while the work is being done. You must be sure your beam pockets are strong enough for the weight. another problem is that a steel beam this size is very heavy, How will you place it without a crane? Maybe an army of helpers can lift it. You may want to consider a laminated wood beam, they are lighter than steel.

- Q:How are steel coils protected during storage and transportation?

- Steel coils are typically protected during storage and transportation through various methods such as applying anti-corrosion coatings, wrapping them in protective materials like plastic or paper, and securing them with strapping or banding to prevent damage or movement.

- Q:How are steel coils used in the production of agricultural implements?

- Steel coils are used in the production of agricultural implements as they are typically rolled into specific shapes and sizes to create parts such as blades, tines, and plowshares. These coils provide the necessary strength and durability required for farm machinery to withstand the demanding conditions of agricultural work.

- Q:Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with a zinc-nickel alloy. Zinc-nickel alloy coating provides excellent corrosion resistance and is commonly used in various industries including automotive, construction, and manufacturing.

- Q:What are the common coil transportation options?

- The common coil transportation options include trucking, rail transport, and sea freight.

- Q:What are the different types of steel coil slitting lines?

- In the metal processing industry, various types of steel coil slitting lines are utilized to cut large coils of steel into narrower strips for different applications. 1. Loop Slitting Lines: The industry commonly employs loop slitting lines, which consist of a decoiler to hold the coil, a slitter head for cutting the coil into strips, and a recoiler to wind the strips into smaller coils. These lines are versatile and can handle different coil widths and thicknesses. 2. Scrap Chopper Slitting Lines: Similar to loop slitting lines, scrap chopper slitting lines incorporate a scrap chopper unit. This unit eliminates excess material from the coil edges before slitting, enhancing efficiency and reducing waste. 3. Double Loop Slitting Lines: For high-speed slitting of thin-gauge coils, double loop slitting lines are utilized. These lines feature two looping pits, enabling continuous operation. While one coil is processed, the other is prepared for slitting, minimizing downtime. 4. Turret Head Slitting Lines: Designed for high-volume production, turret head slitting lines can process multiple coils simultaneously. They are equipped with a turret head containing multiple slitter knives that can be swiftly rotated to switch between different coil widths, resulting in faster and more efficient production. 5. Rotary Shear Slitting Lines: Rotary shear slitting lines are suitable for thicker and harder materials. Instead of a slitter head, they employ a rotary shear to cut the coil into strips. The rotary shear offers improved cutting performance and can handle higher tensile strength materials. 6. Combination Slitting Lines: Combination slitting lines are versatile machines that can handle various materials and perform both slitting and cut-to-length operations. They are ideal for smaller manufacturers or those requiring flexibility in their production process. Ultimately, the choice of steel coil slitting line depends on the manufacturer's specific requirements, including the type of material, desired strip width, and production volume.

- Q:How are steel coils processed for specific applications?

- Steel coils go through a series of meticulously planned steps to be processed for specific applications. The process commences with the selection of the appropriate steel grade and thickness, which is based on the requirements of the end application. Upon receiving the steel coils, they undergo a series of processing steps to transform them into the desired product. The first step in processing steel coils is referred to as uncoiling, where the coil is unwound and straightened to ensure it is flat and ready for further processing. Next, the uncoiled steel is cleaned to eliminate any dirt, oil, or rust on the surface. This is typically done through pickling, a process that involves immersing the steel in an acid bath to remove impurities. Once cleaned, the steel undergoes various shaping processes depending on the desired application. This can involve slitting, where the coil is cut into narrower strips, or shearing, where it is cut into specific lengths. These shaping processes often require specialized machinery capable of handling the high strength and thickness of the steel. After shaping, the steel may undergo additional processes to enhance its properties. For instance, it can be heat treated to increase strength or hardness, or it can go through a coating process to improve corrosion resistance. Coating techniques can include galvanizing, where a layer of zinc is applied to the steel, or painting, where a layer of paint is added. Finally, the processed steel coils are inspected for quality and undergo any necessary finishing processes. This can involve trimming the edges to remove irregularities, or applying protective coatings to prevent damage during transportation or storage. In conclusion, processing steel coils for specific applications is a complex and carefully controlled process. It involves a combination of shaping, cleaning, coating, and finishing processes to ensure that the steel meets required specifications and is suitable for use in various industries such as automotive, construction, and manufacturing.

- Q:How are steel coils used in the production of household goods?

- Steel coils are used in the production of household goods as they are a primary material for manufacturing various products. They are commonly used in appliances, such as refrigerators, stoves, and washing machines, as well as in furniture, shelving units, and even construction materials. The steel coils are typically shaped, cut, and formed into specific components or structures required for these household goods, ensuring durability and strength in the final products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Coil with No Spangle in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords