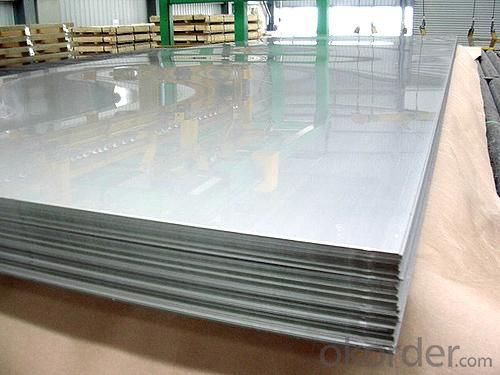

Stainless Steel Sheet 304 with Mill Test Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet in china alibaba

Product Description

Stainless steel sheet Detailed introduction

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What is the width of the carbon steel coil and the width of the stainless steel coil, one is 1250, and the other is 1219?

- Domestic stainless steel rolling mill is generally 1219, but the design standard is 1300, so there will be flash board 1250, that is not the standard board, belonging to the flash, waste materials, many products manufacturers are also in 1219 as a reference size, product development, if the plate width will be wasted, a lot of scrap production the process, so the business order is generally around 1219 stainless steel coil.

- Q: Can stainless steel sheets be painted or coated?

- Yes, stainless steel sheets can be painted or coated. However, it is important to properly prepare the surface by cleaning and applying a suitable primer before painting or coating to ensure adhesion and durability of the finish.

- Q: What are the different types of stainless steel sheet finishes for medical applications?

- There are several different types of stainless steel sheet finishes that are commonly used for medical applications. These finishes are designed to provide specific qualities and characteristics that are necessary for medical environments. One common finish is the 2B finish, which is a smooth, reflective finish that is achieved through a cold-rolling process. This finish is often used in medical equipment and instruments as it is easy to clean and has a high corrosion resistance. Another commonly used finish is the No. 4 finish, also known as a satin finish. This finish has a brushed appearance and is often used in medical cabinets and surfaces. It provides a good combination of aesthetics and functionality, as it is easy to clean and has good corrosion resistance. For more specialized applications, there are also finishes such as the No. 8 mirror finish. This finish is highly reflective and is often used in surgical instruments and other high-end medical equipment. It provides a visually appealing surface and has excellent corrosion resistance. In addition to these finishes, there are also other options such as the bead blast finish, which creates a matte surface with a textured appearance. This finish is often used for medical equipment that requires a non-reflective surface. Overall, the choice of stainless steel sheet finish for medical applications depends on the specific requirements of the equipment or surface. Each finish has its own advantages and characteristics, and it is important to select the appropriate finish to ensure the best performance and longevity in a medical environment.

- Q: Can stainless steel sheets be customized in terms of size and shape?

- Yes, stainless steel sheets can be customized in terms of size and shape. Stainless steel is a highly versatile material that can be easily manipulated and transformed to meet specific requirements. Whether it is a large sheet or a small one, stainless steel can be cut, shaped, and resized to fit the desired dimensions. This customization process can be achieved through various techniques such as cutting, bending, welding, and forming. Additionally, stainless steel sheets can also be perforated or embossed to add further customization and enhance their aesthetic appeal. Overall, stainless steel sheets offer great flexibility in terms of size and shape customization, making them suitable for a wide range of applications in industries such as construction, automotive, aerospace, and more.

- Q: How do you prevent galling on stainless steel sheets?

- To prevent galling on stainless steel sheets, it is important to use lubricants or anti-seize compounds during the manufacturing or assembly process. This helps reduce friction and surface adhesion, minimizing the risk of galling. Additionally, using proper cutting tools and techniques, such as slow speeds and low feed rates, can also help prevent galling.

- Q: Can stainless steel sheets be used for food processing?

- Yes, stainless steel sheets are commonly used in food processing due to their excellent corrosion resistance, durability, and ease of cleaning. They do not react with food, making them safe for use in various food processing applications such as food preparation surfaces, equipment, and storage containers.

- Q: How do you drill holes in stainless steel sheets?

- To drill holes in stainless steel sheets, you will need to use a high-quality drill bit specifically designed for stainless steel. It is advisable to use a drill press or a stable drilling platform to ensure accuracy and prevent slippage. To reduce heat and friction, lubricate the drill bit with cutting fluid or a suitable lubricant. Begin by marking the desired hole locations on the sheet with a center punch, then start drilling at a slow speed, gradually increasing the speed as you progress. Be cautious not to apply excessive pressure to avoid damaging the sheet or causing the drill bit to break.

- Q: How do you determine the best grade of stainless steel sheet for a specific application?

- Determining the best grade of stainless steel sheet for a specific application involves considering several factors. Firstly, it is important to assess the environmental conditions the sheet will be exposed to, such as temperature, humidity, and potential exposure to corrosive substances. This will help determine the required corrosion resistance of the stainless steel. Secondly, the mechanical properties required for the application should be considered. This includes factors like strength, hardness, and ductility. The intended use of the stainless steel sheet, whether it is for structural purposes or for a decorative application, will help determine the necessary mechanical properties. Additionally, the fabrication process and any subsequent treatments or finishes should be taken into account. Some grades of stainless steel may be more suitable for forming, welding, or machining, depending on their composition and characteristics. Furthermore, it is important to consider the cost implications of different stainless steel grades. Higher grades often come with a higher price tag, so it is crucial to balance the required performance with the available budget. To determine the best grade of stainless steel sheet, it is advisable to consult with experts in the field, such as stainless steel suppliers or engineers with expertise in materials selection. They can provide guidance based on their knowledge and experience, taking into consideration the specific requirements of the application.

- Q: Can stainless steel sheets be used for medical instruments?

- Yes, stainless steel sheets can be used for medical instruments. Stainless steel is a common material choice in the medical industry due to its excellent corrosion resistance, durability, and ease of sterilization. It is widely used in various medical instruments such as surgical tools, implants, and equipment due to its hygienic properties and ability to withstand harsh cleaning and sterilization processes.

- Q: Are stainless steel sheets suitable for chemical reactors?

- Yes, stainless steel sheets are indeed suitable for chemical reactors. Stainless steel is highly resistant to corrosion, which makes it an ideal material for handling various chemicals and withstanding harsh environments. Its durability, strength, and ability to maintain structural integrity under high temperatures and pressure make stainless steel sheets a reliable choice for chemical reactor construction. Additionally, stainless steel's non-reactive nature ensures that it does not contaminate or react with the chemicals being processed, ensuring the integrity and safety of the reactor.

Send your message to us

Stainless Steel Sheet 304 with Mill Test Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords