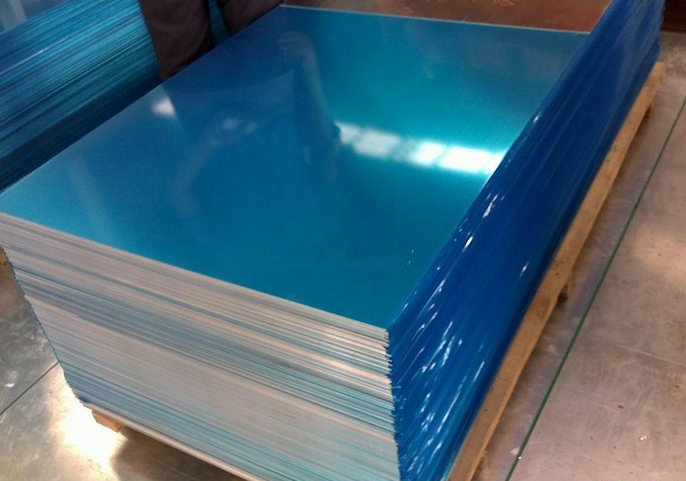

310 cold rolled stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of 310 STAINLESS STEEL SHEET.

STAINLESS STEEL SHEET IS ONE POPULAR PRODUCTS IN CHINA MARKET, IT HAVE SEVERAL DIFFERENT APPLICATIONS, SUCH AS, CONSTRUCTION, BUILDING, DECORATION, ETC.

THE GRADE ALSO INCLUDE: 200 SERIES, 300 SERIES, 400 SERIES, ETC.

Mainly applied in the industry of furniture, sports equipment, compressed containers, shipbuilding, railway and the automotive.

2、Main Features of the 304 STAINLES STEEL SHEET.

High intensity

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance

Wide applicability.

Length per spool only for reference

Spool Size Weight Specifications

D300mm 6Kg~7Kg 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.6mm

5、FAQ of 310 STAINLESS STEEL SHEET.

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are stainless steel sheets resistant to humidity?

- Yes, stainless steel sheets are highly resistant to humidity. Their composition, primarily consisting of iron, chromium, and nickel, forms a protective layer that prevents corrosion and rusting even in high humidity environments. This makes stainless steel sheets an excellent choice for applications where moisture resistance is crucial, such as in kitchen and bathroom fixtures, outdoor structures, and marine equipment.

- Q: What is the width of the carbon steel coil and the width of the stainless steel coil, one is 1250, and the other is 1219?

- Domestic stainless steel rolling mill is generally 1219, but the design standard is 1300, so there will be flash board 1250, that is not the standard board, belonging to the flash, waste materials, many products manufacturers are also in 1219 as a reference size, product development, if the plate width will be wasted, a lot of scrap production the process, so the business order is generally around 1219 stainless steel coil.

- Q: Can stainless steel sheets be used in food processing industries?

- Yes, stainless steel sheets are commonly used in food processing industries due to their excellent corrosion resistance, hygiene, and durability. The smooth and non-porous surface of stainless steel makes it easy to clean and maintain, ensuring sanitary conditions. Additionally, stainless steel is resistant to chemicals and can withstand high temperatures, making it suitable for various food processing applications such as equipment, storage tanks, and work surfaces.

- Q: What are the different types of stainless steel sheet patterns available?

- There are several different types of stainless steel sheet patterns available, each with its own unique design and characteristics. Some of the most common patterns include: 1. Plain or smooth: This is the most basic and common pattern, featuring a smooth and simple surface without any visible texture or design. 2. Brushed or satin: This pattern is achieved by brushing the surface of the stainless steel sheet with a fine grit abrasive, creating a consistent directional grain. It provides a subtle and elegant look. 3. Diamond or quilted: This pattern features a raised diamond-shaped design on the surface of the stainless steel sheet, providing enhanced traction and slip resistance. It is commonly used for flooring, stairs, and industrial applications. 4. Linen: This pattern resembles the texture of linen fabric, with a series of parallel lines etched onto the surface of the stainless steel sheet. It adds a unique visual appeal and can be used in various applications, including interior design and architectural projects. 5. Perforated: This pattern consists of a series of small holes or perforations punched into the stainless steel sheet, creating a visually interesting and functional design. It is commonly used in applications that require ventilation or filtration. 6. Checker or tread: This pattern features a raised checkerboard design on the surface of the stainless steel sheet, providing a non-slip surface. It is commonly used for flooring, stairs, and transportation equipment. These are just a few examples of the different types of stainless steel sheet patterns available. Each pattern offers a different aesthetic and functional value, allowing for versatile use in a wide range of applications.

- Q: How do I remove stains or marks from stainless steel sheets?

- To effectively eliminate stains or marks on stainless steel sheets, a few simple steps can be taken: 1. Initiate the process by cleansing the stainless steel surface with warm water and a mild detergent or dish soap. Take a soft cloth or sponge and gently scrub the affected area. Rinse thoroughly with clean water and dry with a towel. 2. If the stain persists, the utilization of white vinegar can be attempted. Dampen a cloth or sponge with vinegar and gently rub the stained area. The acidic properties of vinegar aid in breaking down the stains. Rinse the surface with water and dry it completely. 3. In the case of more stubborn stains or marks, a paste can be concocted using baking soda and water. Apply the paste to the affected area and gently rub it in using a soft cloth or sponge. Allow it to sit for a few minutes, then rinse with water and dry thoroughly. 4. Should the aforementioned methods prove ineffective, resorting to a stainless steel cleaner specifically designed for stain or mark removal is advisable. Adhere to the instructions on the cleaner's packaging for optimal results. Remember to rinse the surface thoroughly and ensure complete drying after employing a commercial cleaner. 5. It is essential to refrain from using abrasive cleaners, steel wool, or harsh chemicals on stainless steel sheets, as they possess the potential to scratch or damage the surface. Additionally, it is recommended to always test any cleaning method or product on a small, inconspicuous area before applying it to the entire surface. By adhering to these steps and utilizing appropriate cleaning methods, stains or marks can be effectively eradicated from stainless steel sheets, thereby restoring their original shine and appearance.

- Q: Can stainless steel sheets be used for architectural columns?

- Yes, stainless steel sheets can be used for architectural columns. Stainless steel is a versatile and durable material that can withstand various weather conditions and provide a modern and sleek aesthetic to architectural designs. It is commonly used in architectural applications, including columns, due to its corrosion resistance, strength, and aesthetic appeal.

- Q: Can stainless steel sheets be used for storage racks?

- Yes, stainless steel sheets can be used for storage racks. Stainless steel is a durable and corrosion-resistant material, making it ideal for storage racks that may be exposed to moisture or other harsh conditions. Stainless steel sheets can be fabricated into various shapes and sizes to suit different storage needs, and they can support heavy loads without warping or bending. Additionally, stainless steel is easy to clean and maintain, ensuring a hygienic storage environment. Overall, stainless steel sheets are a reliable choice for storage racks in industries such as food and beverage, pharmaceuticals, and warehouses.

- Q: Can stainless steel sheets be used for elevator interiors?

- Elevator interiors can indeed incorporate stainless steel sheets. Stainless steel proves to be a favored material for elevator interiors due to its durability, aesthetic appeal, and low maintenance. Its resistance to corrosion, scratches, and stains makes it an excellent choice for heavily frequented areas such as elevators. Moreover, stainless steel sheets can be customized to meet specific elevator design requirements and are available in a range of finishes, including brushed, mirrored, or patterned, offering a sleek and contemporary appearance. Furthermore, stainless steel is effortless to clean and sanitize, a crucial consideration in public spaces like elevators where hygiene is of utmost importance. In summary, stainless steel sheets present a versatile and pragmatic solution for elevator interiors.

- Q: What are the different types of patterned finishes available for stainless steel sheets?

- Stainless steel sheets come in a variety of patterned finishes, each offering a unique aesthetic and functionality. Some of the most commonly used finishes include: 1. Diamond: This finish has a raised diamond-shaped texture on the surface, providing better grip and slip resistance. It is often used for flooring or industrial equipment. 2. Linen: The linen finish resembles woven fabric, adding a subtle elegance to stainless steel sheets. It is commonly used in interior design applications like wall cladding or decorative panels. 3. Checkered: This finish creates a checkerboard-like appearance with a grid of raised squares or rectangles. It adds visual interest and can give a retro or industrial look to stainless steel sheets. 4. Bead Blasted: In this finish, fine glass beads are blasted onto the surface to create a matte texture with a slightly rough surface. It is often used in architectural applications to provide a modern and uniform appearance while reducing glare and fingerprints. 5. Etched: This finish involves chemically altering the surface to create intricate patterns or designs. It can range from simple line patterns to complex images and is commonly used for decorative purposes like signage, artwork, or custom designs. 6. Sandblasted: Similar to bead blasting, sandblasting uses high-pressure sand or other abrasive materials to create a textured surface. It provides a rougher and more pronounced pattern, making it suitable for industrial or rugged applications. 7. Mirror: Although not technically a patterned finish, the mirror finish is highly popular for stainless steel sheets. It is achieved through a series of polishing and buffing processes, resulting in a highly reflective surface similar to a mirror. It is commonly used in architectural elements like cladding or decorative accents. In conclusion, the choice of patterned finish for stainless steel sheets depends on the desired aesthetic, functionality, and specific application requirements. Each finish offers a distinct look and texture, providing endless possibilities in design.

- Q: Can stainless steel sheets be cut or welded?

- Indeed, it is possible to cut and weld stainless steel sheets. Various methods, such as shearing, plasma cutting, laser cutting, or waterjet cutting, can be utilized to cut stainless steel sheets. When it comes to welding, the process involves joining two pieces together by heating them to their melting points and, if needed, incorporating a filler material. Nevertheless, it is crucial to acknowledge that welding stainless steel necessitates specific techniques and equipment due to its distinctive attributes, including low thermal conductivity and high thermal expansion. Consequently, it is imperative to possess adequate training and expertise to guarantee a fruitful and high-quality weld.

Send your message to us

310 cold rolled stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords